Method for hot-dip coating flat steel products containing 2-35% by weight mn and flat steel products

A technology of hot-dip plating and finished products, applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of coating shedding, cracks, inability to meet economic and ecological needs, etc., and achieve good wettability The effect of wet, long-lasting connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

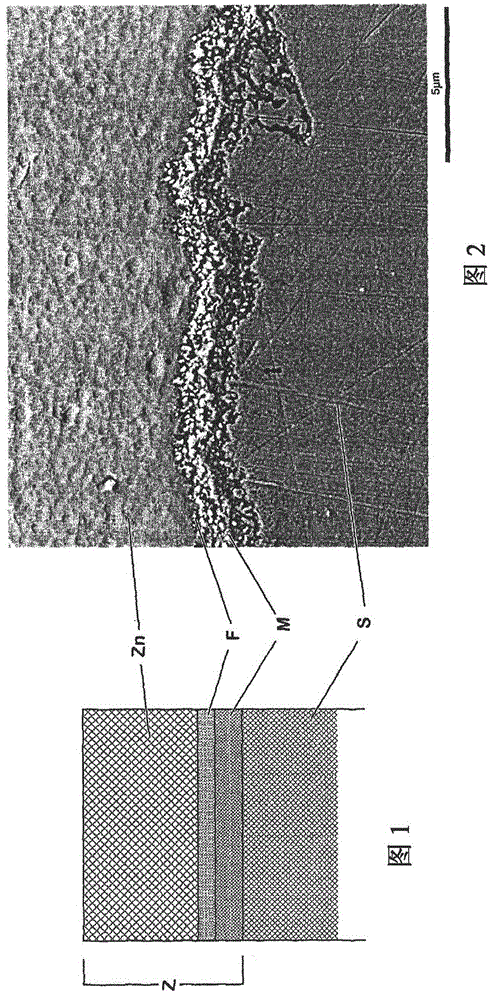

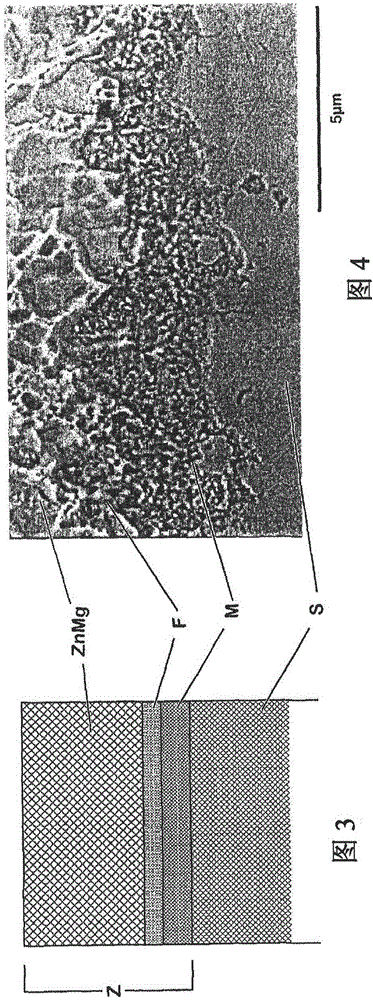

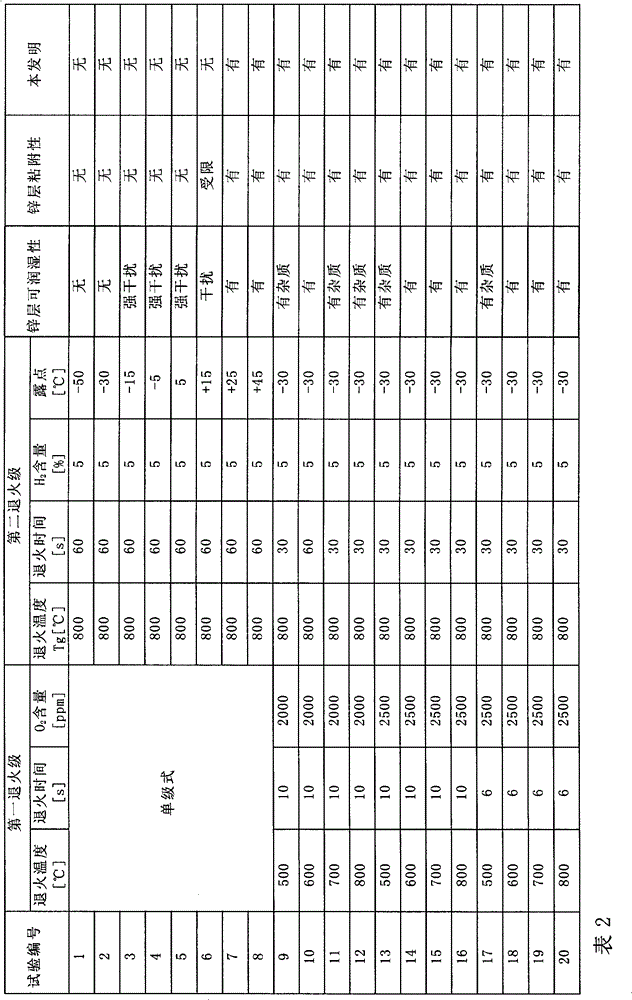

[0050] High manganese steel having the composition shown in Table 1 was produced into cold strip in a known manner.

[0051] C mn P Si V Al Cr Ti Nb 0.634 22.2 0.02 0.18 0.2 0.01 0.08 0.001 0.001

[0052] residual iron and unavoidable impurities,

[0053] Expressed in % by weight.

[0054] Table 1

[0055] Then, the first sample of the cold-rolled strip was annealed in a single-stage annealing process.

[0056] For this purpose, a steel strip sample was heated at a heating rate of 10 K / s to an annealing temperature of 800° C., and the sample was then kept at this condition for 30 seconds. Here, the annealing is carried out in an annealing atmosphere with up to 5% by volume of H 2 and up to 95% by volume of N 2 composition, and a dew point of +25°C. Next, the annealed steel strip was cooled to a bath temperature of 480° C. at a cooling rate of 20 K / s, and then overaged for 20 seconds under this condition. H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com