Carbon calcinations rotary kiln secondary wind pipe installation structure and installation method

A secondary air duct and installation structure technology, applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problem that the protective layer of refractory castable cannot be laid in advance, the installation structure of the secondary air duct is unreasonable, and maintenance personnel operate Harsh environment and other problems, to achieve the effect of health protection, avoid a large drop in temperature, and prevent scald accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

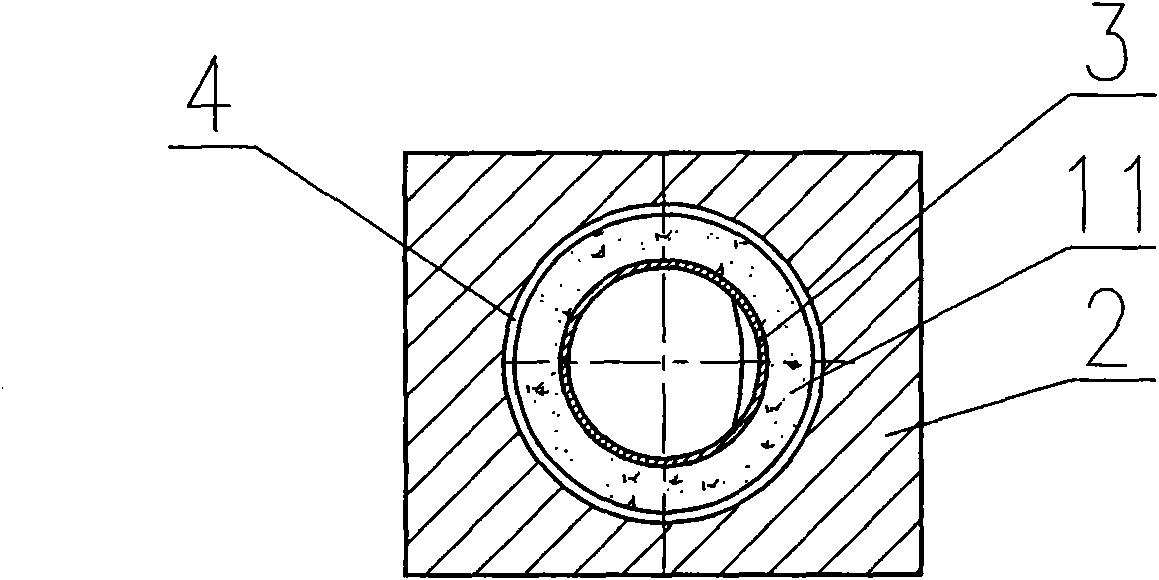

[0029] Such as Figure 1-3 As shown, the carbon calcination rotary kiln secondary air duct installation structure of the present invention includes a rotary kiln shell 1 and a kiln lining 2, and the rotary kiln shell 1 and the kiln lining 2 are provided with an installation hole 4, and the installation hole 4 is provided with There is a secondary air duct 3 with a refractory castable protective layer 11, and the end of the secondary air duct 3 outside the installation hole 4 is provided with an end flange 9, and the end flange 9 is connected to the fan, and the secondary air duct 3 Heat-resistant steel pipe is used, and the sealing sleeve 5 is put on the secondary air pipe 3 outside the rotary kiln cylinder 1. The sealing sleeve 5 is welded on the kiln outer skin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com