Hydraulic eight-arm anchor rod drill carriage for coal mine

A bolter and hydraulic technology, which is applied in the installation of bolts, drilling equipment, mining equipment, etc., can solve the problems of four-arm bolter bolting speed lagging behind continuous coal mining machines, etc., to solve the problem of mining and Contradictory support, reliable stability, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

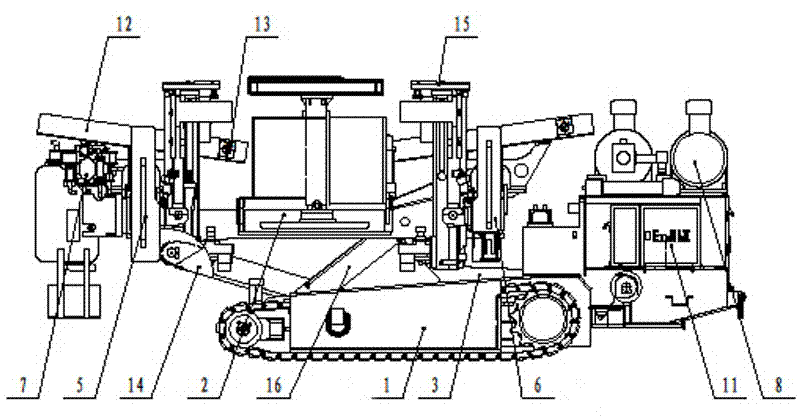

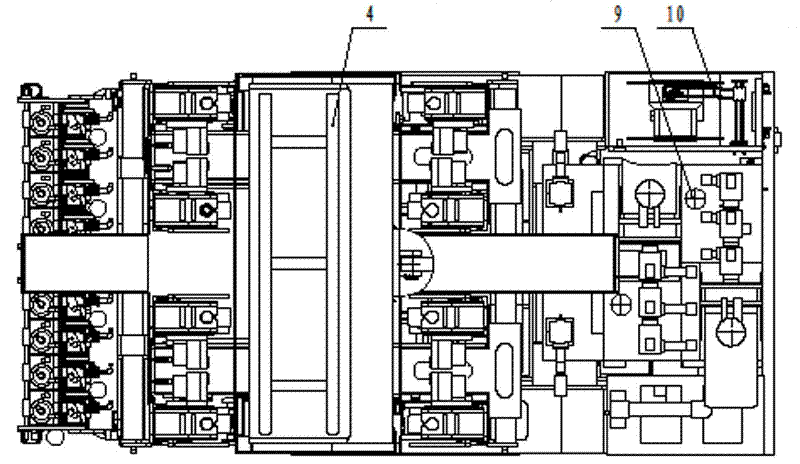

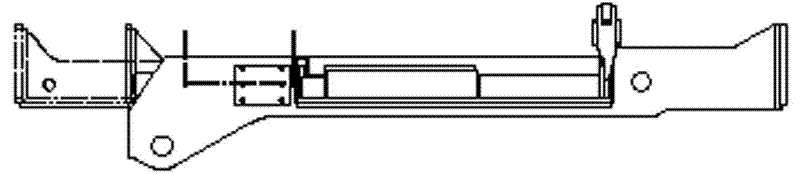

[0029] The specific embodiments of the present invention will be further described with reference to the drawings.

[0030] 1. The layout of the whole machine.

[0031] The invention mainly consists of a frame, a workbench, a temporary support, a ceiling, a connecting rod mechanism, front and rear slide rails, a coiled cable, a hydraulic system, an electrical system, an anchor drilling system, a dust removal system, etc.

[0032] In the case of the same width as the four bolt rigs, and slightly changed machine height and captain length, four drill booms, four sets of dust removal systems, and the volume of the hydraulic oil tank are increased. Eight bolts can be supported at the same time at the same time, which can meet the bolt support of 4500-6000 roadways. Under better roadway conditions, the practical performance is improved to ensure the tunneling speed of the roadway.

[0033] The main technical parameters of the invention:

[0034]

[0035] 2. Highly integrated dust removal sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com