Chemical flooding injection method for improving recovery rate of crude oil

A chemical flooding and recovery technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of alkali agent consumption increasing the cost of oil extraction, restricting the promotion and application of industrialization, and damage to formations and oil wells. Achieve the effect of enhancing oil recovery, increasing swept volume, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is further described below in conjunction with specific embodiment:

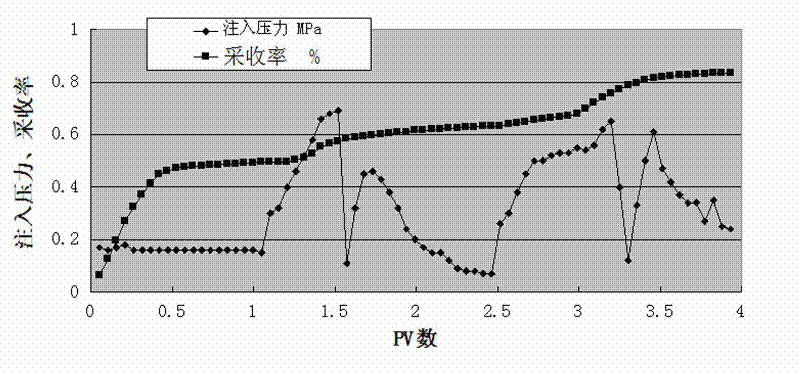

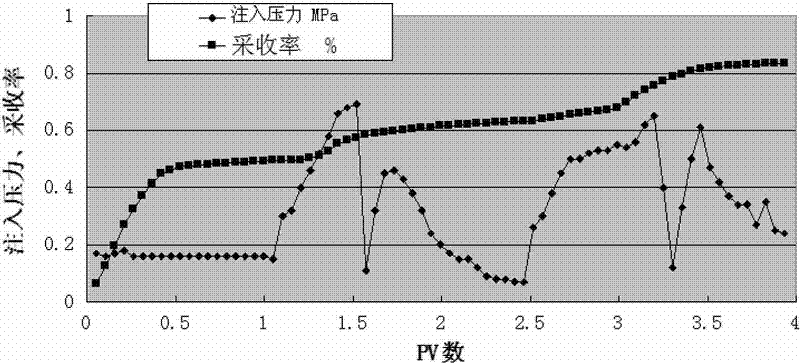

[0008] Chemical flooding injection method for enhanced oil recovery: ① After polymer flooding, inject 0.3PV emulsifier slug with concentration of 1700mg / L; ②Reinject polymer with molecular weight of 25 million and concentration of 1500mg / L, concentration % (wt) surfactant binary compound slug 0.4PV. The emulsifier slug is composed of: functional polymer 1000mg / L, T-60 500mg / L, sodium tripolyphosphate 200mg / L, and water as the balance.

[0009] Chemical flooding injection method 2 for enhanced oil recovery: ① After polymer flooding, inject emulsifier slug 0.2PV with a concentration of 2250mg / L; % (wt) surfactant binary compound slug 0.4PV. The emulsifier slug is composed of: functional polymer 1500mg / L, OP-2 500mg / L, citric acid 250mg / L, and water as the balance.

[0010] Chemical flooding injection method three for enhanced oil recovery: ① inject 0.25PV emulsifier slug wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com