Method for productive preparation of silver-plated fibers

A silver-plated fiber and metal silver technology, which is applied in fiber treatment, plant fiber, textiles and paper making, etc., can solve the problems of silver antibacterial effect, poor adhesion, high pollution, etc., and achieve strong bactericidal effect, low cost and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

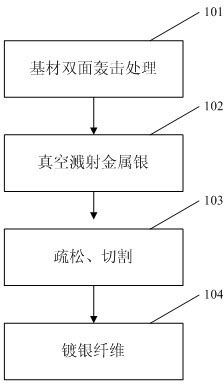

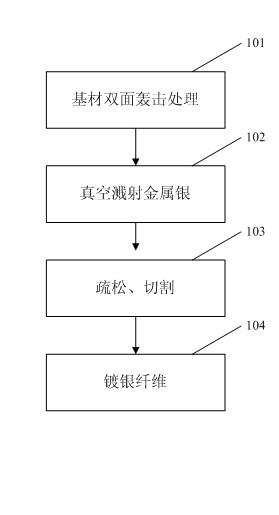

[0018] Such as figure 1 as shown, figure 1 It is a flowchart of the production and preparation method of the silver-plated fiber of the present invention. In step 101, a certain pressure of argon gas is introduced into the vacuum chamber, and the substrate is bombarded on both sides by using plasma or ion source equipment in the front chamber of the vacuum machine. Among them, the base material is chemical fiber fabric or non-woven fabric, chemical fiber fabric includes: polyester cloth, nylon cloth, cloth base specification is 180T-360T, fiber filament diameter is 10-80um, specification is 20dtex / 1f-24f to 75dtex / 1f-24f; the non-woven fabric is polyester spunlace non-woven fabric, nylon non-woven fabric, viscose non-woven fabric, cellulose non-woven fabric, etc., with a thickness of 0.05-0.4mm and a weight of 30-120g / m2 . During double-sided bombardment treatment, impurities such as oil stains and particles attached to the surface of the substrate can be removed. The pro...

Embodiment 1

[0024] Preparation of silver-coated fiber of polyester spunlace non-woven fabric

[0025] 1. The substrate is polyester spunlace non-woven fabric with a weight of 80g / m2 and a width of 1.2m.

[0026] 2. Under the protection of argon gas in the vacuum chamber, the above substrates are first bombarded on both sides with ion source equipment, the temperature is 55°C, the vacuum degree is 20Pa, and the substrate running speed is 1.5 m / min;

[0027] 3. Continuously carry out vacuum sputtering of metallic silver on the base material after plasma bombardment in the same vacuum chamber, the temperature is 110° C., the vacuum degree is 0.15 Pa, and the running speed of the base material is 1.5 m / min.

[0028] (Steps 2 and 3 are performed continuously and simultaneously in the same vacuum chamber)

[0029] 4. The polyester spunlace non-woven fabric with silver-plated fibers is prepared through the above process, and then loosened by a specific method to prepare silver-plated staple fi...

Embodiment 2

[0031] Preparation of silver-plated fibers on nylon knitted fabric

[0032] 1. Substrate, nylon knitted fabric, thickness 0.35mm, width 1.2m.

[0033] 2. Under the protection of argon gas in the vacuum chamber, the above substrates are first bombarded on both sides with an ion source, the temperature is 55°C, the vacuum degree is 30Pa, and the substrate running speed is 1.8 m / min;

[0034] 3. Continuously carry out vacuum sputtering of metallic silver on the base material after plasma bombardment in the same vacuum chamber, the temperature is 110° C., the vacuum degree is 20 Pa, and the running speed of the base material is 1.8 m / min.

[0035] (Steps 2 and 3 are carried out continuously and simultaneously in the same vacuum chamber)

[0036] 4. The nylon knitted fabric with silver-plated fibers is prepared through the above process, and it is loosened and cut through specific methods to prepare long or short silver-plated fibers according to specific needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com