Elevator traction machine

A technology of elevator traction machine and motor, which is applied to elevators, mechanical equipment, transmission parts in buildings, etc., to achieve the effect of simple and compact, stable operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions and beneficial technical effects of the present invention clearer, the technical content and specific embodiments of the present invention are further described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described in this specification are only for explaining the present invention, and not for limiting the present invention.

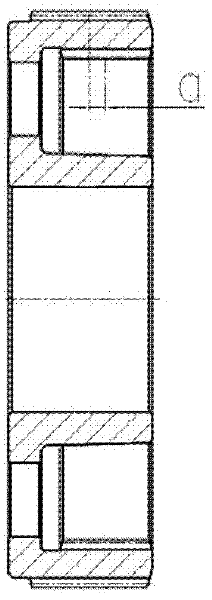

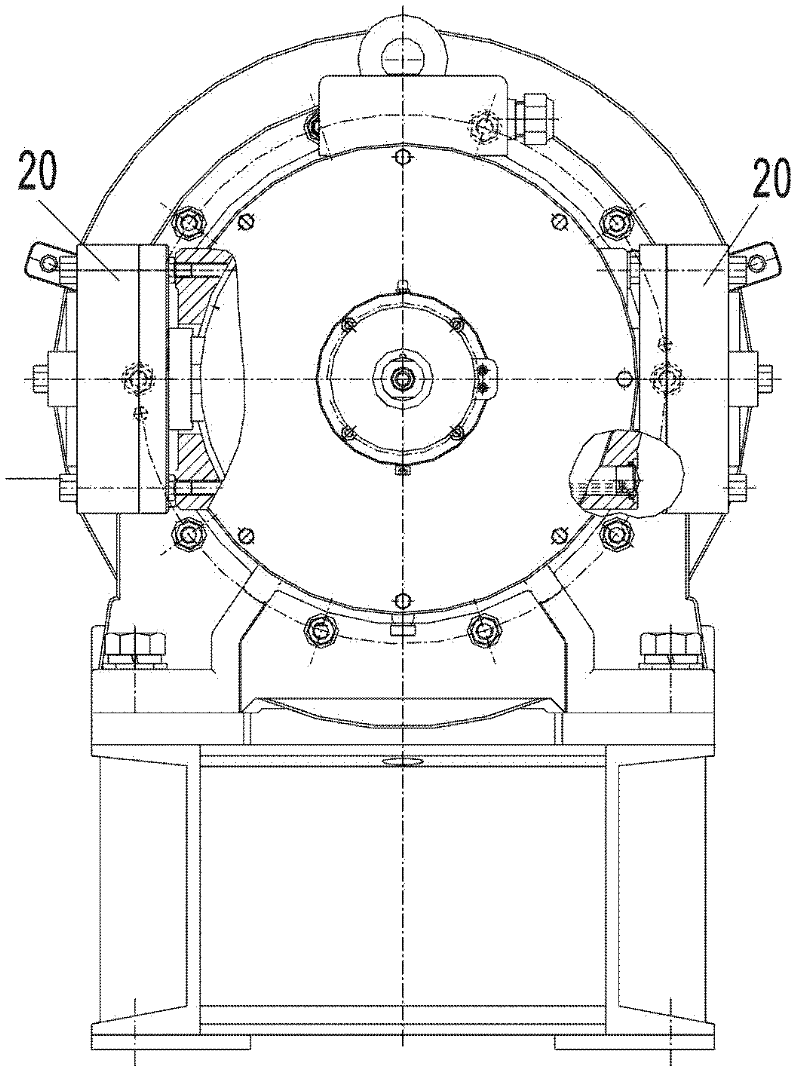

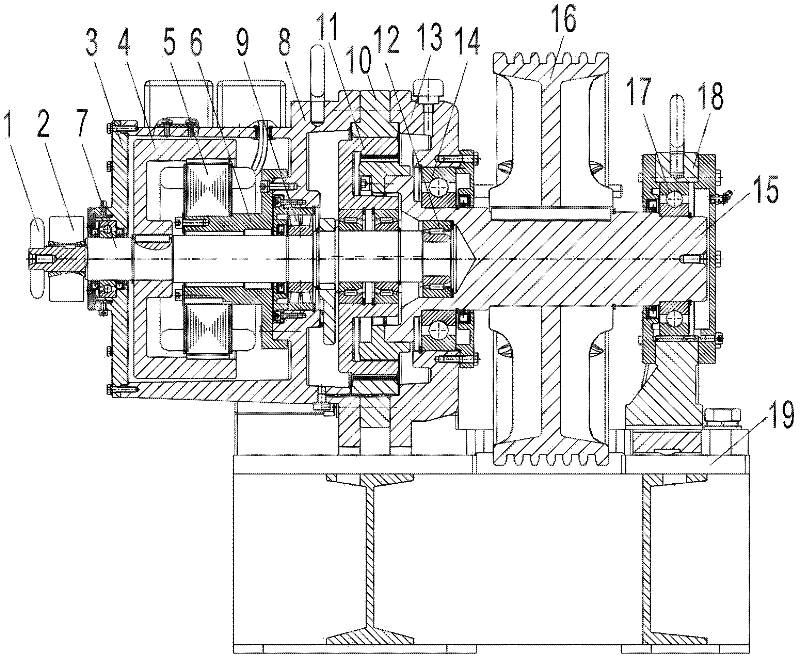

[0018] see Figure 1 to Figure 3 As shown, it is a schematic diagram of the structure and installation of the embodiment of the present invention. The elevator traction machine of the embodiment of the present invention includes a motor, a gear reduction box and a traction sheave 16, wherein the motor is a permanent magnet synchronous motor, and the gear reduction box is a novel involute planetary gear reduction box with small tooth difference. The gear tooth shape of the gear reduction box is modified, and adopts the NN ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com