Dispersion liquid of chemical for rubbers, method for producing same, rubber wet master batch containing chemical for rubbers, rubber composition, and tire

A chemical and dispersion technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problem of large deviation of anti-aging agent content, lower Mooney viscosity, and the enlightenment of the method of high dispersion of rubber chemicals, etc. problem, to achieve good dispersion and improve the effect of heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

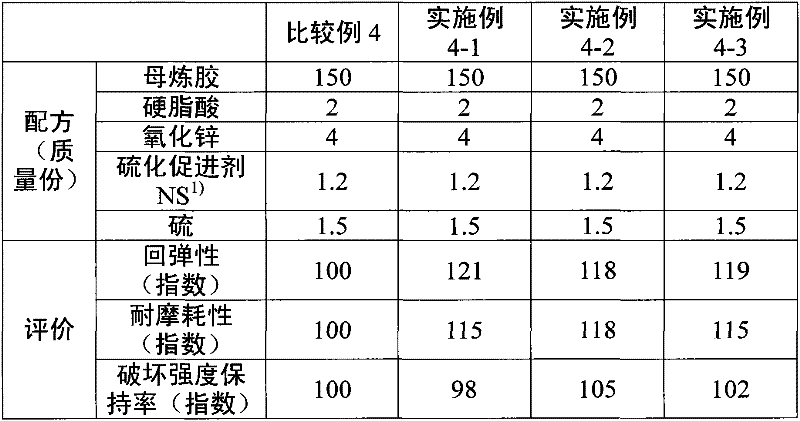

Examples

Embodiment 1

[0131] Example 1 Preparation of white turbid dispersion liquid containing antioxidant 6C and preparation of wet rubber masterbatch

[0132] (1) Preparation of white turbid dispersion containing antioxidant 6C

[0133] The antioxidant 6C (N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine) ["Ozonone 6C" manufactured by Seiko Chemical Co., Ltd.] is dissolved in ethanol as a good solvent , Prepare a 6C solution with a concentration of 10% by mass. Next, the same amount of water as a poor solvent was added to the 6C solution while stirring, and the mixture was stirred at 25°C for 10 minutes to prepare a 6C-containing white turbid dispersion liquid with a 6C concentration of 5 mass%.

[0134] In this white turbid dispersion liquid containing 6C, 96% by mass of all 6C was dispersed as particles, and the average particle diameter (mv) of the particles was 1.7 μm.

[0135] (2) Production of wet masterbatch

[0136] The natural rubber latex with a rubber concentration of 20% by mass and the wh...

Embodiment 2

[0141] Example 2 Preparation of white turbid dispersion liquid containing antioxidant RD and preparation of wet rubber masterbatch

[0142] (1) Preparation of white turbid dispersion containing antioxidant RD

[0143] Except in Example 1(1), the antioxidant RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer) ["Nonflex RD" manufactured by Seiko Chemical Co., Ltd.] is used instead of the antioxidant Except for the agent 6C, it was carried out in the same manner as in Example 1 (1) to prepare an RD-containing white turbid dispersion liquid having an RD concentration of 5% by mass.

[0144] In this white turbid dispersion liquid containing RD, 93% by mass of the total RD was dispersed as particles, and the average particle diameter (mv) of the particles was 0.9 μm.

[0145] (2) Production of wet masterbatch

[0146] Using a natural rubber latex with a rubber concentration of 20% by mass and the RD-containing white turbid dispersion liquid with an RD concentration of 5% by mass obtained in (1...

Embodiment 3

[0151] Example 3 Preparation of white turbid dispersion containing phenolic resin and preparation of wet rubber masterbatch

[0152] (1) Preparation of white turbid dispersion containing phenolic resin

[0153] Except that phenol resin [SP1006N" manufactured by Asahi Organic Materials Co., Ltd.] was used in Example 1 (1) instead of the antioxidant 6C, the same procedure as in Example 1 (1) was carried out to prepare a phenol resin with a concentration of 5% by mass. White turbid dispersion containing phenolic resin.

[0154] In this white turbid dispersion liquid containing the phenol resin, 92% by mass of the total phenol resin was dispersed as particles, and the average particle diameter (mv) of the particles was 2.1 μm.

[0155] (2) Production of wet masterbatch

[0156] The natural rubber latex with a rubber concentration of 20% by mass and the phenolic resin-containing white turbid dispersion with a phenolic resin concentration of 5% by mass obtained in (1) above are used so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com