Method for multifunctional pipe inspection and material testing, and apparatus thereof

A material testing and multi-functional technology, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc. It can solve the problems that are difficult to test the tensile and compressive properties of gradient materials, and achieve fast and accurate testing. , Eliminate measurement error, reduce the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

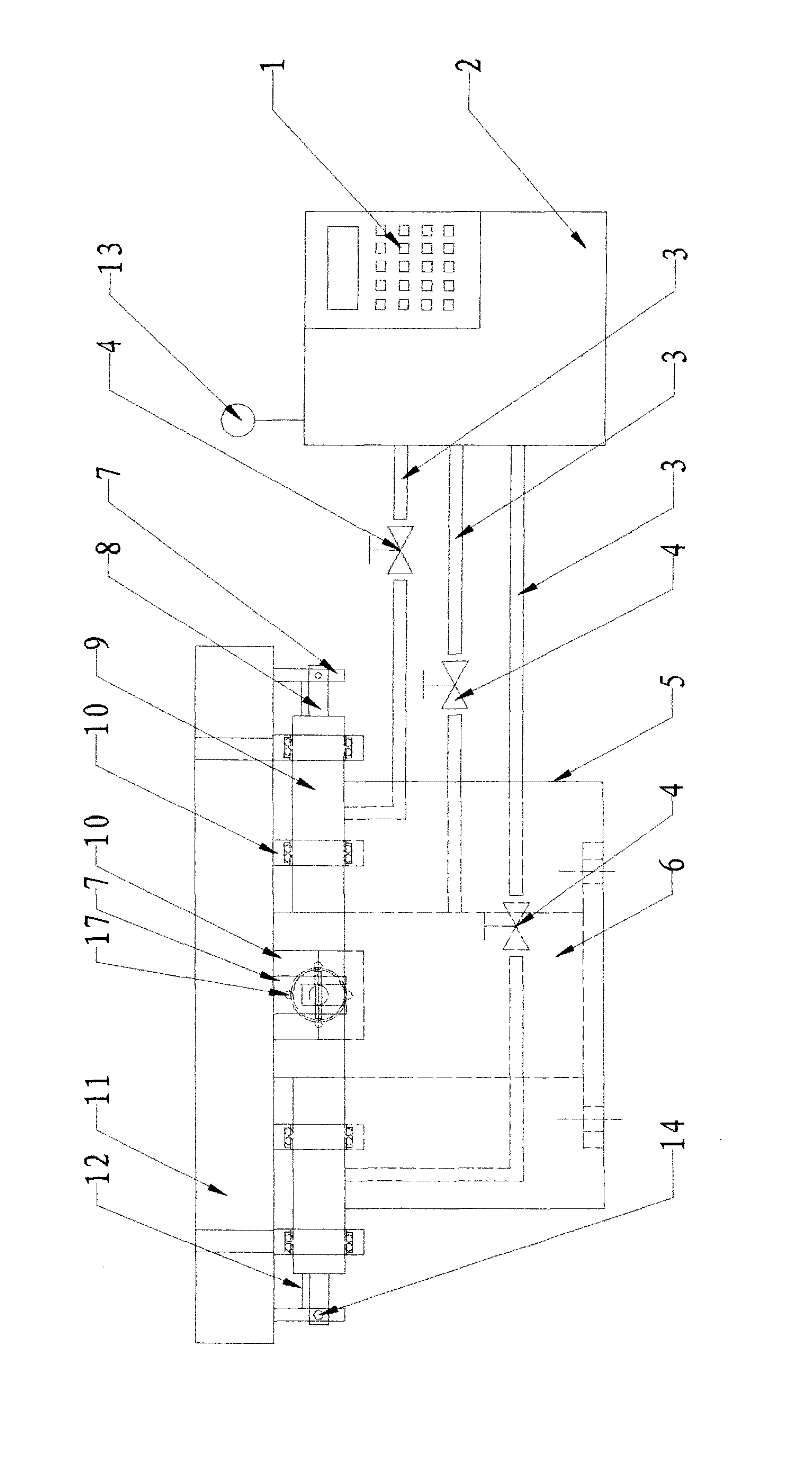

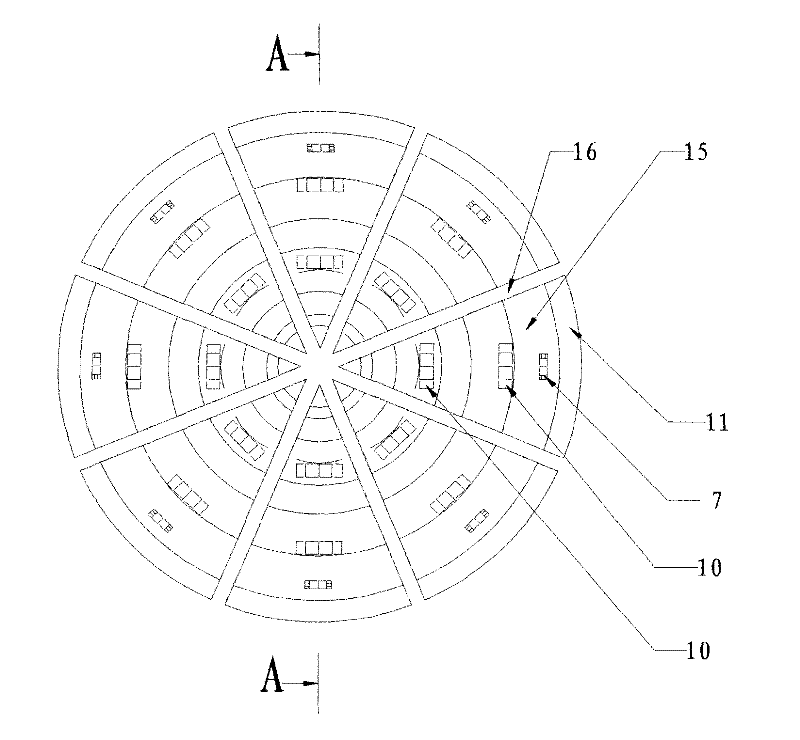

[0043] Equal to 8 (n=4) as embodiment with the block number 2n of concentric fan-shaped plate 11, as attached figure 1 , 2 3. Further explain the present invention: the multifunctional pipe inspection and material testing device described in this embodiment can respectively inspect four kinds of PE pipes and material properties with outer diameters of 110, 200, 315 and 500 mm.

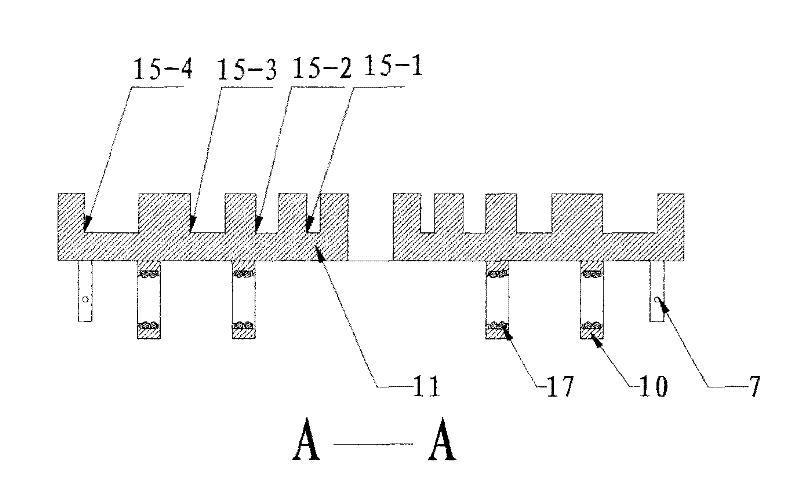

[0044] Four kinds of PE pipes with outer diameters of 110, 200, 315 and 500mm are compared with the PE pipe specification and size table to obtain the average wall thickness respectively. On a plane of a steel disc with a thickness of 60mm and a diameter of 550mm, 4 concentric annular grooves 15 are processed, and the dimensions of each concentric annular groove 15 are as follows:

[0045] Groove 1: outer diameter 112mm, inner diameter 88mm, depth 35mm;

[0046]Groove 2: outer diameter 202mm, inner diameter 162mm, depth 35mm;

[0047] Groove 3: outer diameter 318mm, inner diameter 256mm, depth 35mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com