Interface pressure distribution testing sensing element

A sensing element and pressure distribution technology, which is applied in the field of interface pressure distribution testing sensing elements, can solve the problem of inability to obtain field characteristics, unsuitable for rock soil/structure interface pressure distribution measurement, and inability to measure interface pressure distribution and changes and other problems, to achieve the effect of high force-sensitive precision, thin structure and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

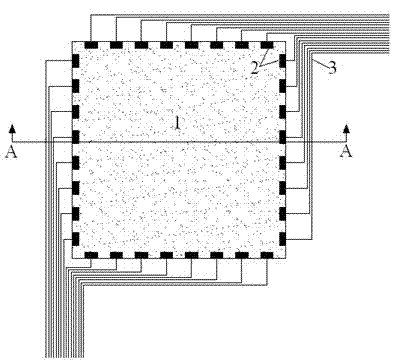

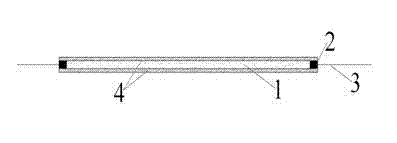

[0016] Embodiment 1, as figure 1 image 3 As shown, the interface pressure distribution test sensing element is a square, which includes a sensing film 1, electrodes 2 evenly spaced around the sensing film 1, and wires 3 are connected to the electrodes 2. The upper and lower surfaces of the sensing film 1 and A layer of insulating and sealing insulating paint layer 4 is sprayed on the connection of the electrodes 2 respectively. The sensing film 1 is made of carbon black-filled rubber-based conductive composite material, with a thickness of 50 μm, a square sensing element with a side length of 200 mm, 32 electrodes with 8 evenly spaced on each side, and the electrodes are made of copper with a thickness of 0.1 mm. The size is 5mm×10mm, and each electrode 2 is connected with a wire. The electrode 2 and the sensing film 1 are bonded with conductive glue, and the wire 3 is welded with the electrode 2 .

Embodiment 2

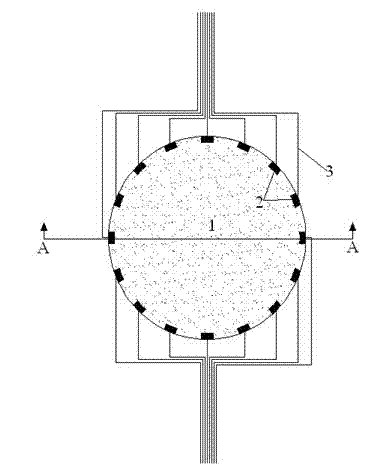

[0017] Embodiment 2, as figure 2 image 3 As shown in the figure, the interface pressure distribution test sensing element is circular, which includes a sensing film 1, electrodes 2 evenly spaced around the sensing film 1, and wires 3 are connected to the electrodes 2. The upper and lower surfaces of the sensing film and A layer of insulating and sealing insulating paint layer 4 is respectively sprayed on the electrode connections. The sensing film 1 is made of a rubber-based conductive composite material filled with carbon nanotubes, with a thickness of 100 μm. The shape of the sensing film 1 is a circle with a diameter of 150 mm, and 16 electrodes are evenly spaced on the circumference. The electrodes are 0.1 mm Thick copper sheets, 5mm x 5mm in size, with wires attached to each electrode. The electrode and the sensing film are bonded with conductive glue, and the wire and the electrode are welded.

[0018] The shape of the sensing film 1 can be determined according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com