Control valve of deep-water blowout preventer

A blowout preventer control, electromagnetic control valve technology, applied in wellbore/well components, servo motor components, sealing/packing, etc., can solve problems such as inability to meet offshore development, equipment dependent on wellheads, slow development, etc. Compact, reliable sealing, and the effect of improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

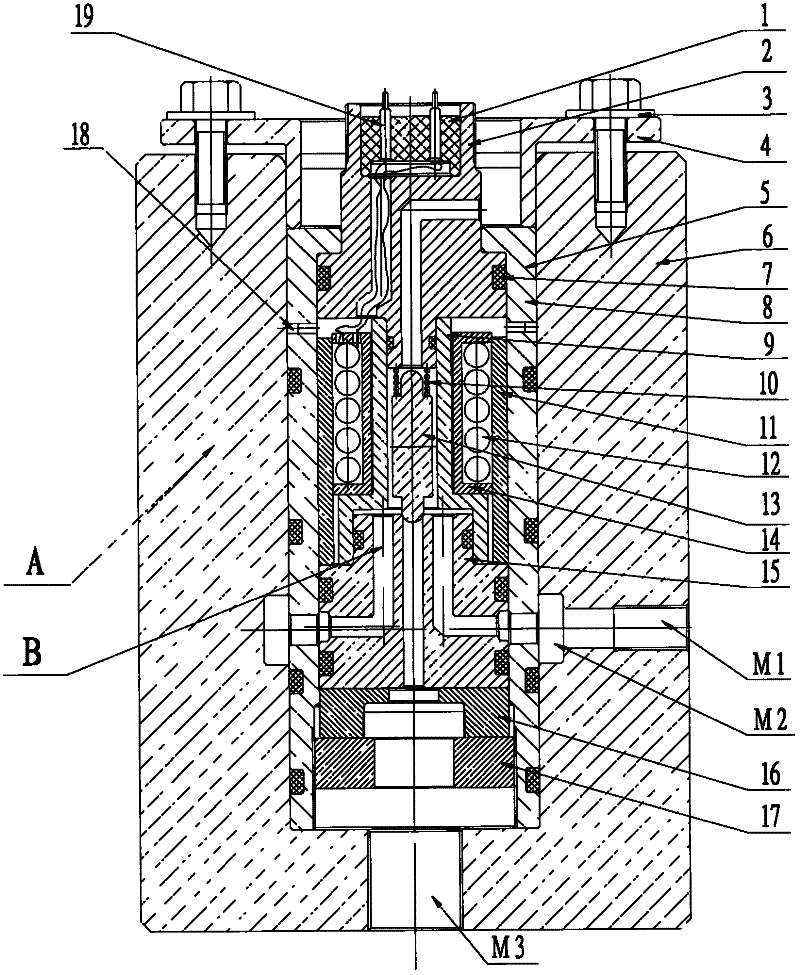

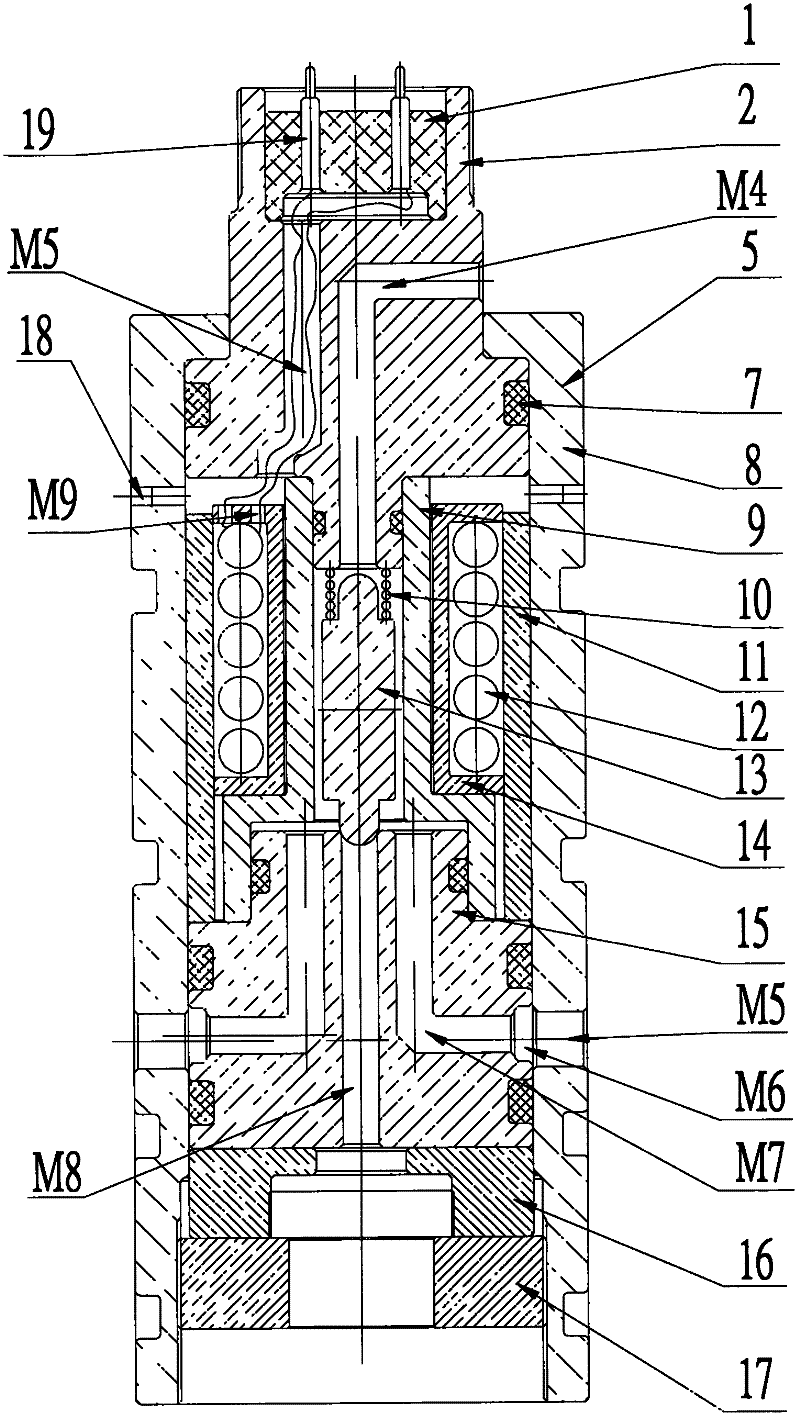

[0015] see figure 1 , figure 2 . The deep water blowout preventer control valve of the present invention includes two parts, a pilot valve A and an electromagnetic control valve B, and the electromagnetic control valve B is installed in the inner chamber of the pilot valve A. The electromagnetic control valve is mainly composed of cable plug 1, upper valve seat 2, bolt 3, gland 4, solenoid valve body 5, pilot valve body 6, sealing ring 7, solenoid valve body 8, isolation ring 9, compression spring 10 , magnetic ring 11, electromagnetic coil 12, iron core 13, electromagnetic coil slot 14, lower valve seat 15, filter grid 16, fastening nut 17, wire plug 18 and thread pin 19 are formed. There is an annular space between the valve body 8 and the isolation ring 9 of the electromagnetic control valve. There are electromagnetic coils 12 and magnetically conductive rings 11 fixedly installed in the annular space; Between the valve and the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com