Authigenic Al3Ni and Si mixed particle aluminium alloy piston for local enhancement and preparation method thereof

A local enhancement, aluminum alloy technology, applied in the direction of piston, mechanical equipment, machine/engine, etc., can solve the problem of Al-Si-Ni ternary alloy gradient functional material research has not been reported, hardness and wear resistance need to be improved, etc. problems, to achieve the effect of smooth and continuous transition of structure and performance, excellent mechanical properties, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

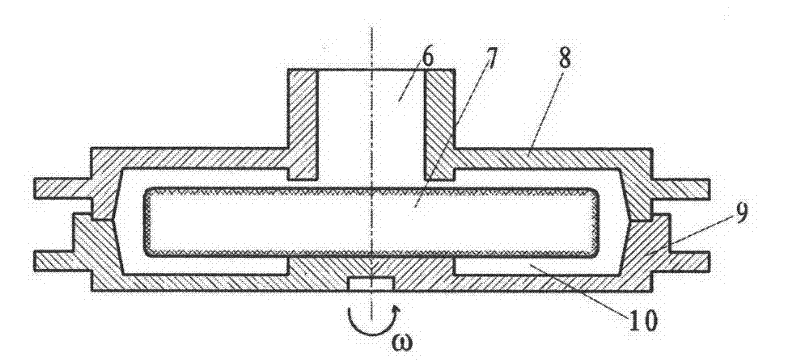

Image

Examples

Embodiment 1

[0022] The alloy composition is Al-18Si-8Ni, and the reinforced area has excellent high temperature resistance and wear resistance.

Embodiment 2

[0024] The alloy composition is Al-18Si-15Ni, and the high temperature resistance and wear resistance of the reinforced area of this embodiment are better than those of Embodiment 1.

Embodiment 3

[0026] The alloy composition is Al-24Si-8Ni, and the high temperature resistance and wear resistance of the reinforced area in this embodiment are better than those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com