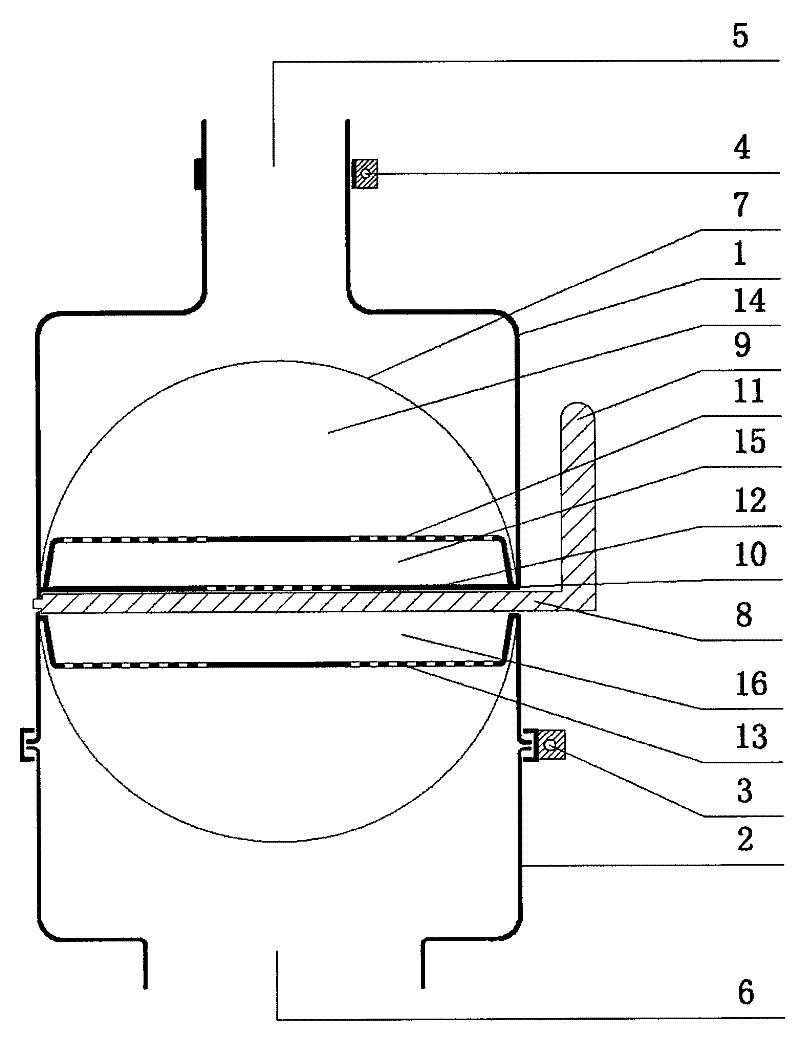

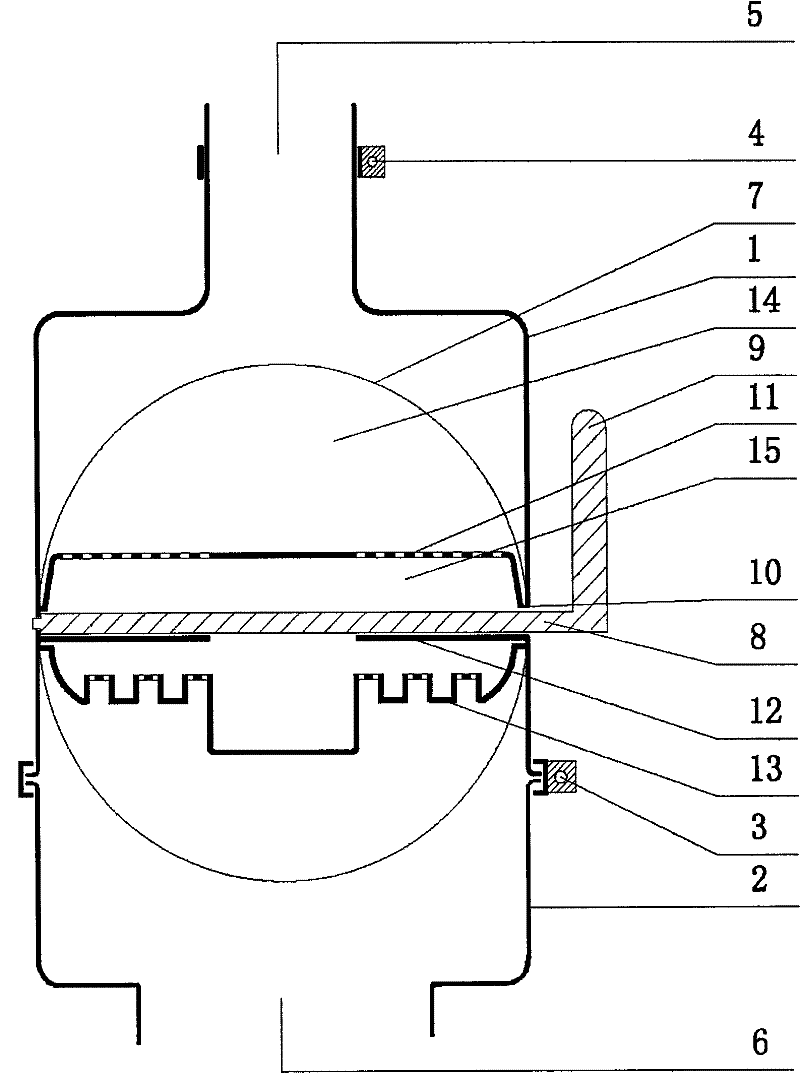

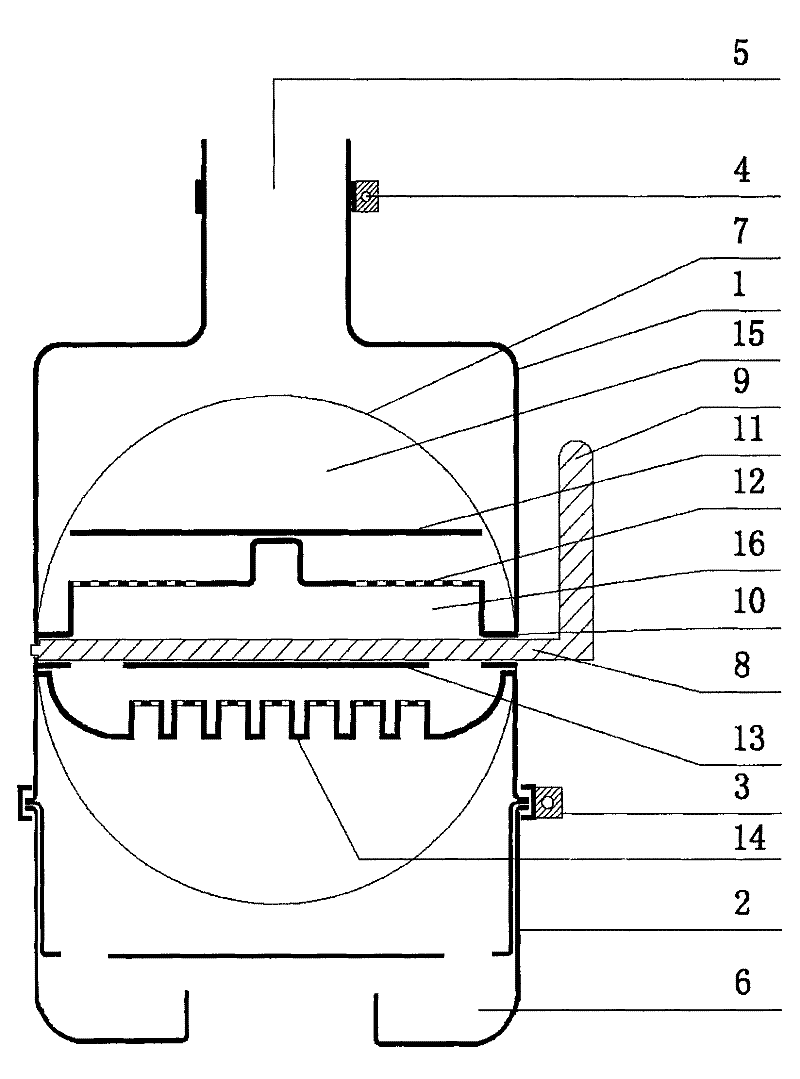

Switchable spiral-flow type exhaust gas spark arrester for automotive vehicle

A spark extinguisher and swirl-type technology, which is applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc., can solve the problem of low separation and collection efficiency of a single filter, and achieve smooth exhaust, flexible configuration, and stable performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] There are two kinds of substances in the engine exhaust, among which the combustion exhaust gas is gas, and the spark particles are solid, so the engine exhaust is a gas-solid flow. In the gas-solid flow, the density of the spark particles is greater than that of the combustion exhaust gas, so the inertial centrifugal force of the spark particles is greater than that of the combustion exhaust gas.

[0020] When the motor vehicle is running in a safe environment, the sparks in the exhaust have no potential accidents. When the handle is pulled to open the rotary swirl valve core, the air in the shroud cavity is smooth, so the inertial centrifugal force of the gas-solid two-way flow does not It does not appear, and the spark particles float in the combustion exhaust gas and are naturally extinguished after being discharged smoothly. After opening the rotary swirl spool in a safe environment, the exhaust resistance generated when it is closed is eliminated, thereby eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com