Cold-box core blower

A technology of core shooter and cold box, which is applied in the direction of core, molding machine parts, casting and molding equipment, etc., to achieve the effect of reasonable structure, avoiding wall hanging and agglomeration, and improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

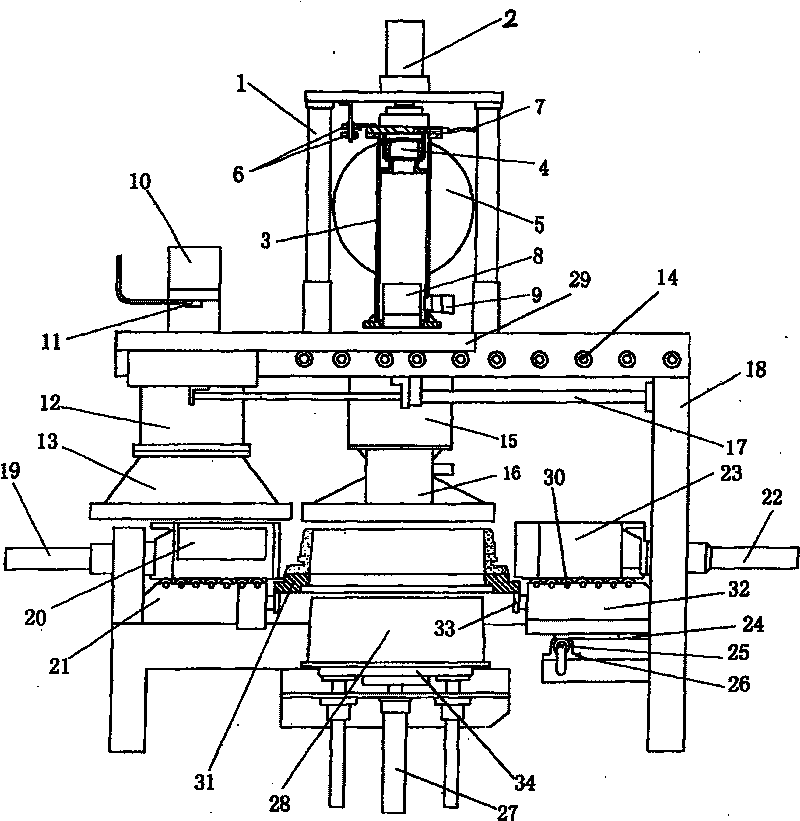

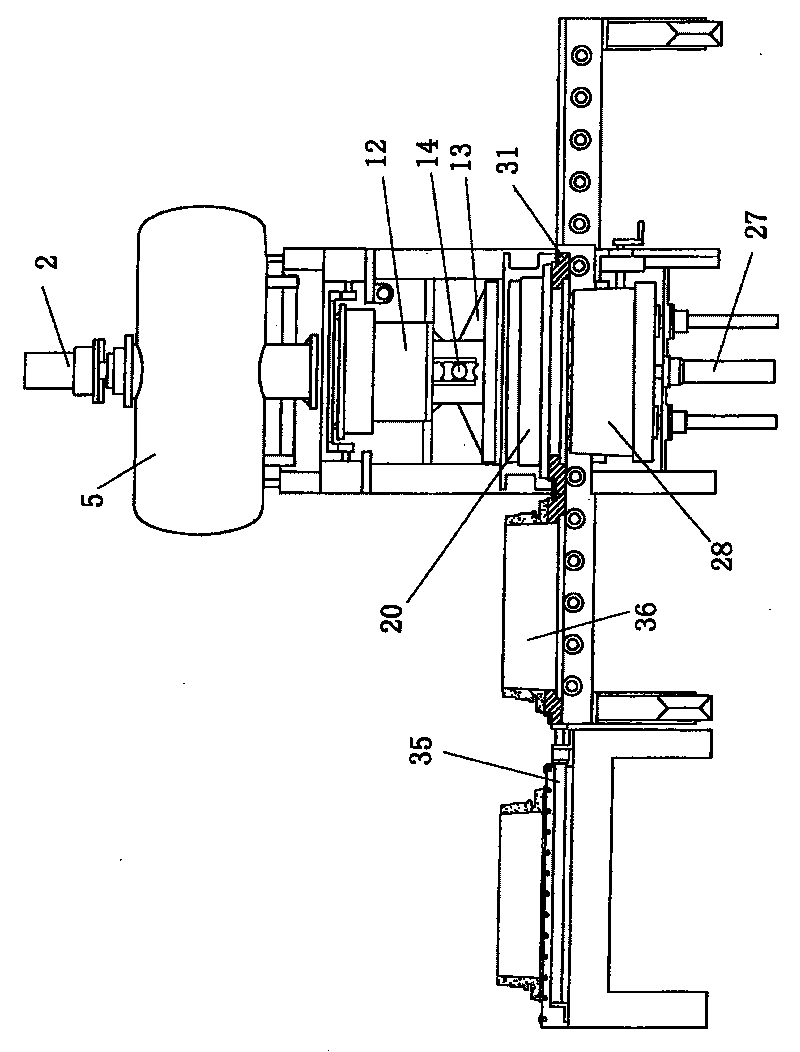

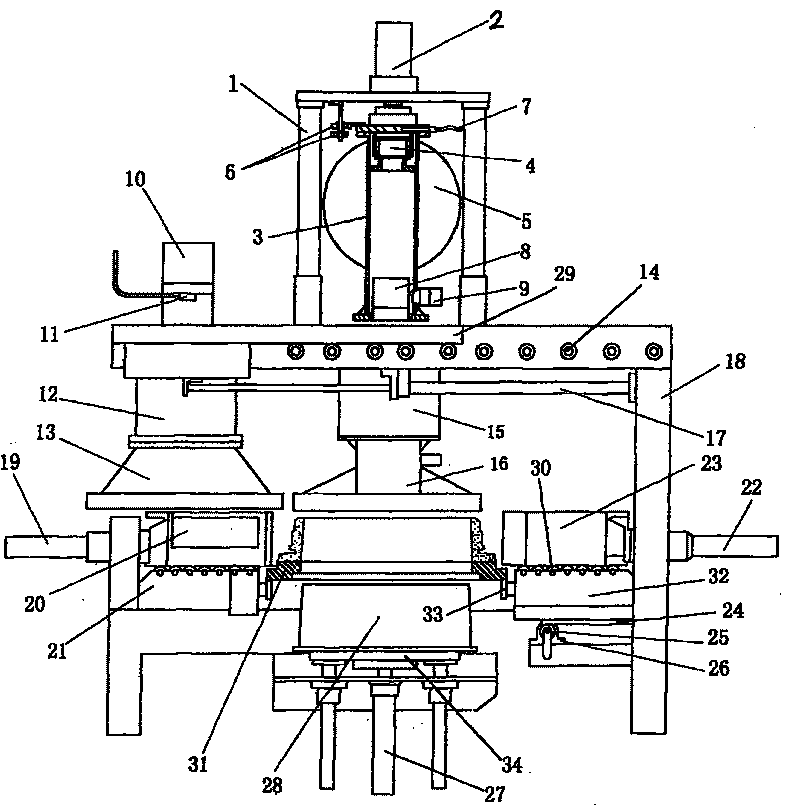

[0022] Such as figure 1 with figure 2 As shown, the cold core box core shooting machine of the present invention includes a frame 18, a raceway 14, a lower compressed air bag 1, a suspended movable shooting cavity 12, a suspension 15 and a core box connecting mechanism with adjustable space.

[0023] The lower compressed air bag 1 is installed at the upper end of the frame 18, and a compression cylinder 2 is installed above the lower compressed air bag 1. The upper part of the frame 18 is provided with a raceway 14, and the raceway 14 is provided with a moving plate 29. Both the injection cavity 12 and the suspension 15 are suspended on the movable plate 29 by springs. The injection cavity 12 or the suspension 15 and the frame 18 The upper moving cylinder 17 is connected, the lower end of the shooting cavity 12 is equipped with a shooting head 13, and the lower end of the suspension 15 is installed with a blowing plate 16. Driven by the moving cylinder 17, the suspension 15 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com