Air-tight heat insulation metal roof and construction method thereof

A technology of metal roofing and construction methods, which is applied in the direction of roofing, roof covering, and tools used in roofing engineering. It can solve the problems of not being able to satisfy airtight heat insulation, cumbersome construction procedures, and high construction costs, and achieve rust prevention. And good fire performance, high construction efficiency and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

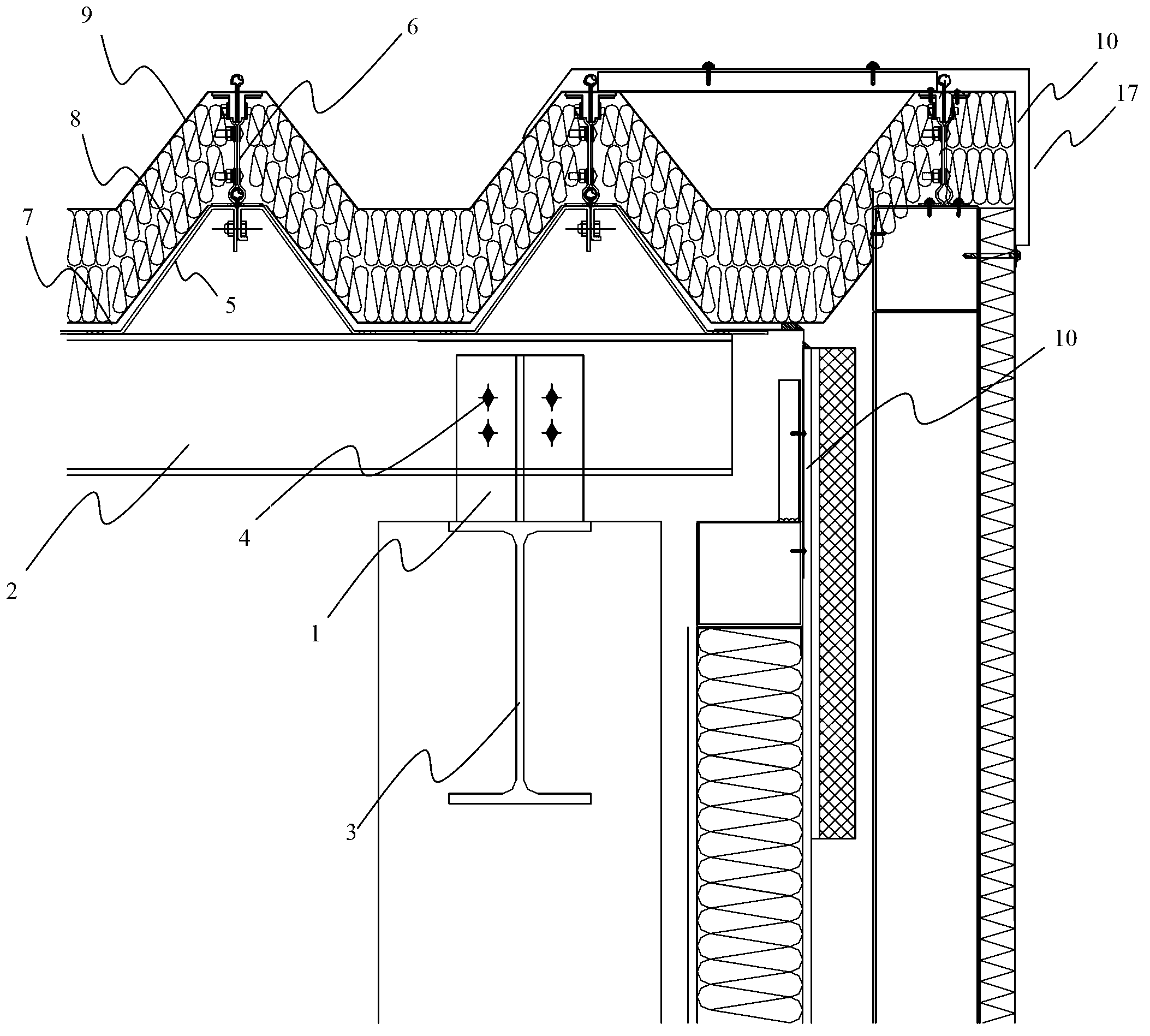

[0043] see figure 1 , a kind of airtight heat insulation metal roof of the present invention, comprises a roof truss 3, also comprises:

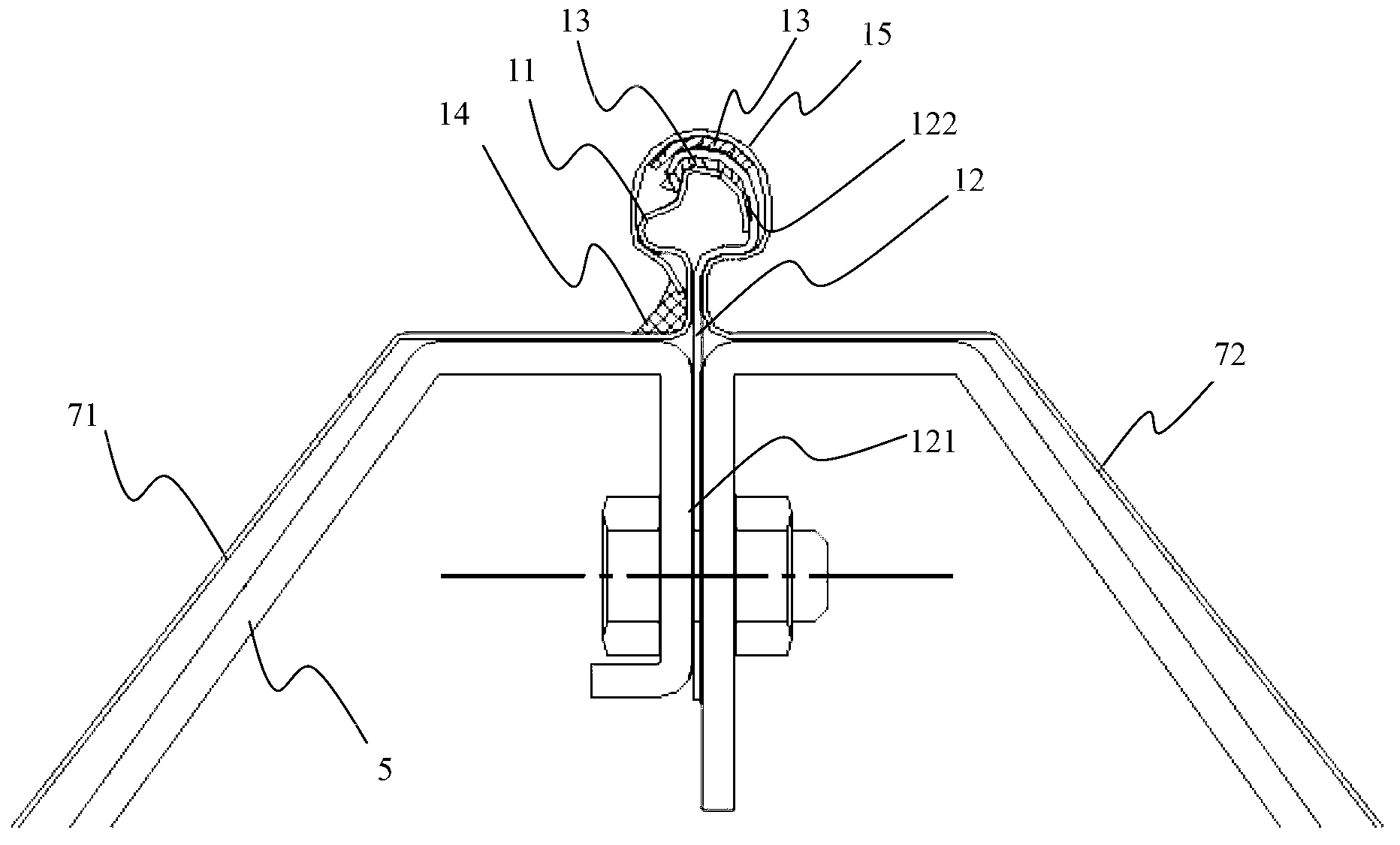

[0044] A plurality of metal bottom plates 7, adjacent metal bottom plates 7 are fastened to each other, and fixed on the purlin 2 through a plurality of fixed bases 5; the purlin 2 is fastened to the purlin support 1 by bolts 4, and the purlin support 1 is welded at a fixed distance On the truss 3; glass wool 8 is laid on the metal bottom plate 7, the glass wool 8 is PE (polyethylene) film glass wool, the thickness of a single layer is 80mm, and the weight is 16kg / m; a plurality of metal top plates 9 are laid on the glass On the cotton 8, adjacent metal top plates 9 are fastened to each other and fixed on the metal bottom plate 7 through a heat-insulating metal fixing seat 6, and the metal top plate 9 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com