Concrete block masonry component fabricated construction method and construction device

A technology of concrete blocks and construction methods, which is applied in the directions of transportation and packaging, building construction, load hanging components, etc., can solve the problems of cumbersome operation of sliders, and achieve the effects of reducing costs, ensuring construction speed, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

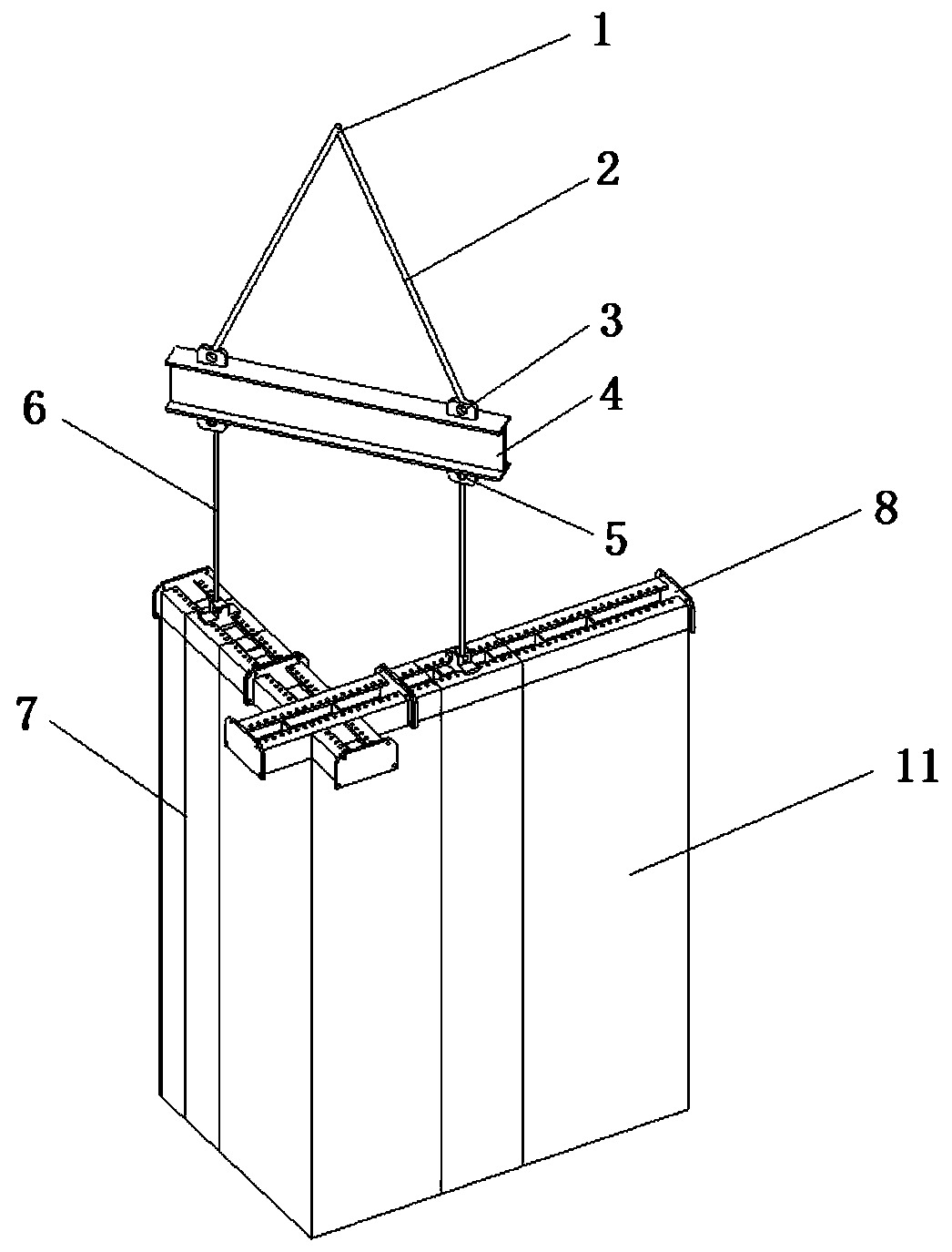

[0047] Specific implementation mode one: see Figure 1-Figure 16 This embodiment will be described. The concrete block masonry component assembly construction method described in this embodiment specifically includes the following steps:

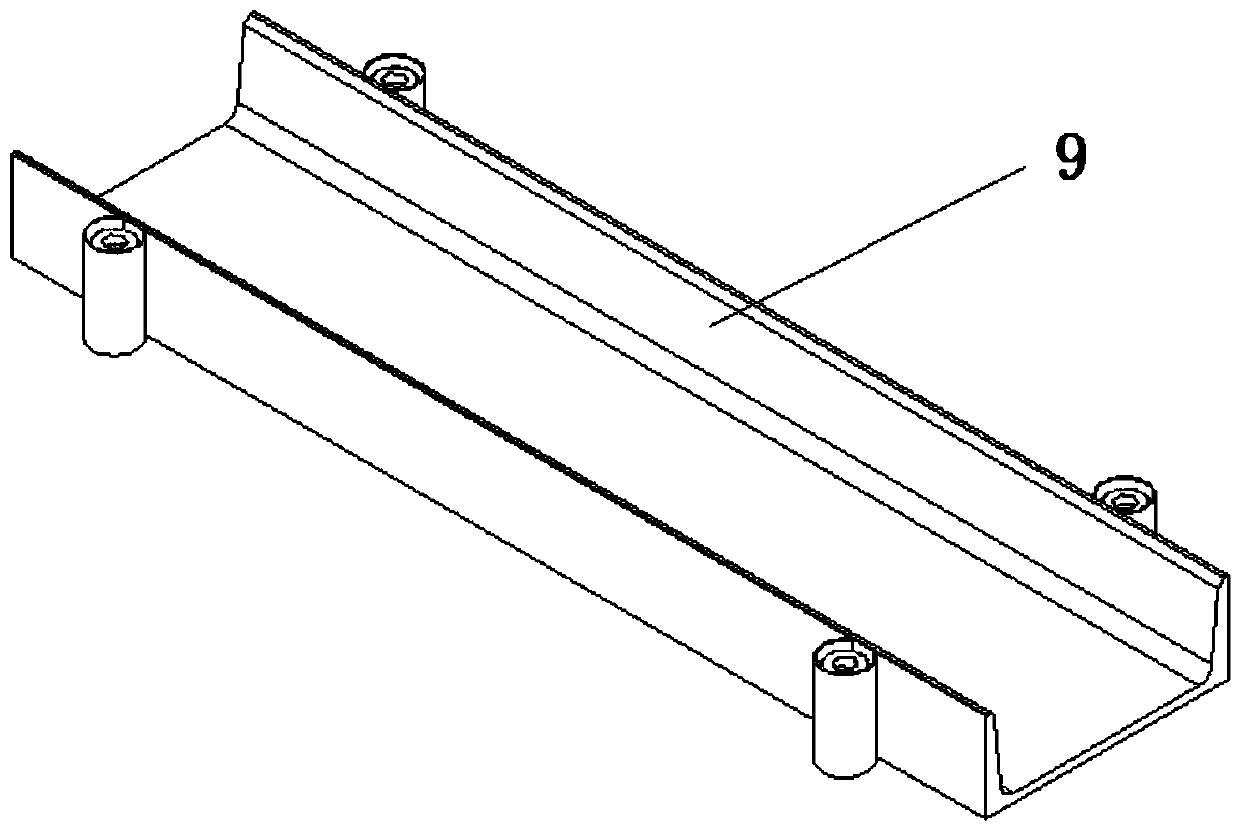

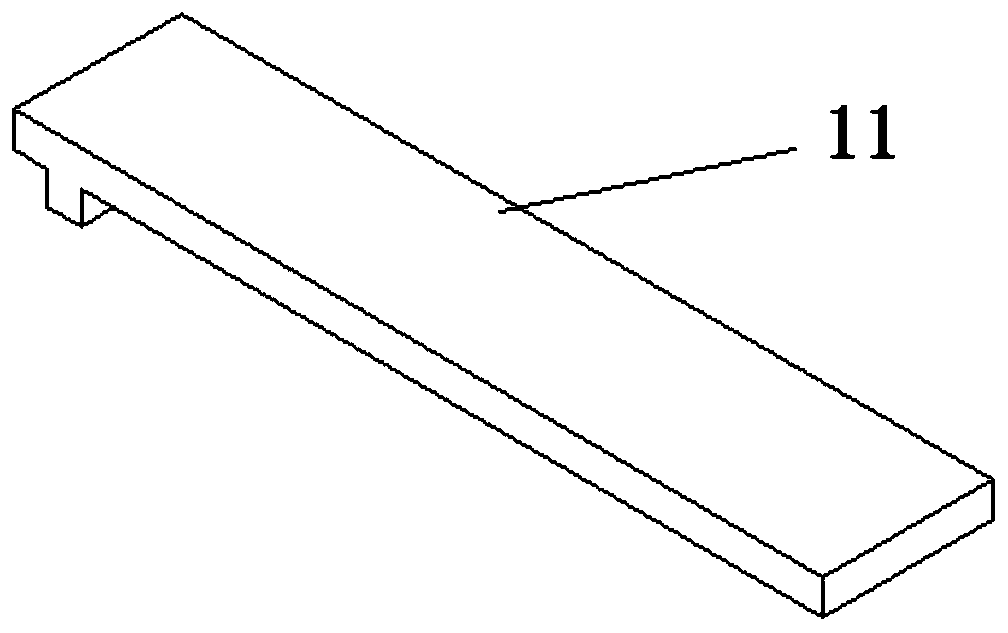

[0048] Step 1: Place the base below the block wall piece 11, place the binding beam 8 above, and then bind the binding beam 8, the block wall piece 11 and the base vertically together through the binding rope 7:

[0049] Step 2: Determine the horizontal position of the hook 1 and calculate the center of gravity position of the block wall piece 11 to be hoisted, that is, the horizontal position where the hook 1 is located;

[0050] Step 3: Select the positions of the two lifting points A1 and A2 in the plan, so that the center of gravity of the block wall piece 11 is on the line connecting the two lifting points A1 and A2, and ensure that the two lifting points A1 and A2 reach the center of gravity is equal in distance; Figure 7 For the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com