Prefabricated offshore booster station upper module and construction method thereof

An offshore booster station, prefabricated technology, applied in enclosed substations, substations, industrial buildings, etc., can solve the problems of many redundant designs, long construction periods, and many crossover operations, achieving high flexibility and reducing crossovers. The effect of homework and saving construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

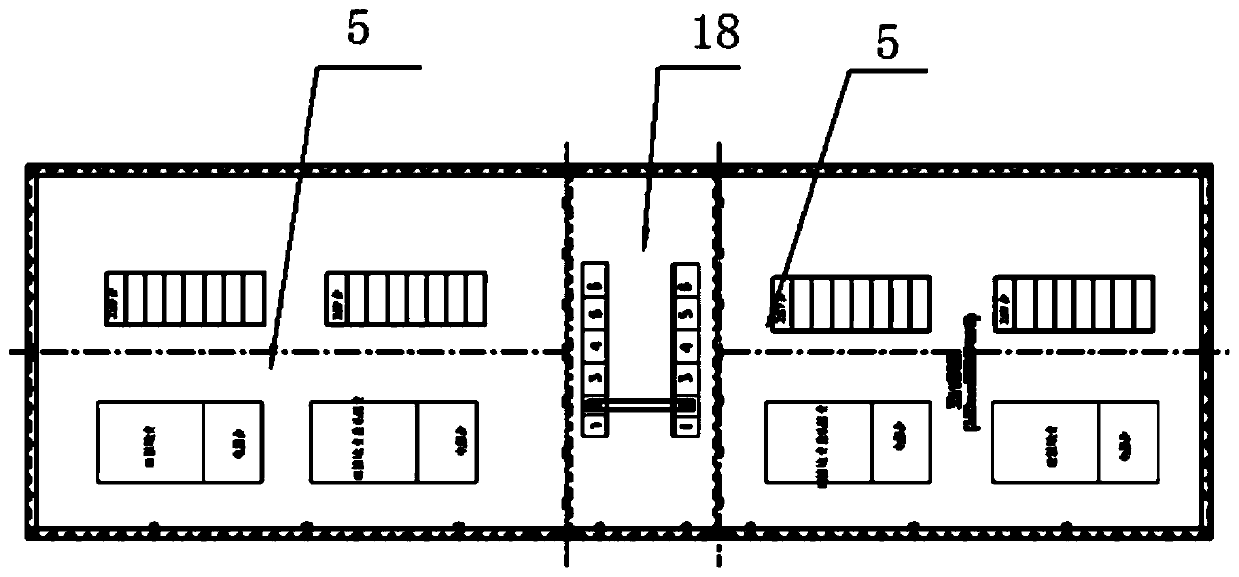

[0043] The invention provides a prefabricated offshore booster station upper block, such as figure 1 As shown, it includes the first deck 2 and the second deck 3 arranged on the jacket 1. The left side of the second deck 3 is provided with a 35KV power distribution room 5 and a screen room 6, and the middle is provided with a main transformer room 7. The GIS power distribution room 8 and the auxiliary equipment room 9 are arranged on the side, and the screen body room 6 is located above the 35KV power distribution room 5, such as Figure 6As shown, the two are connected by a T-hook 10, the auxiliary equipment room 9 is located above the GIS power distribution room 8, and the two are connected by a T-hook 10; the main transformer room 7 and the 35KV power distribution room 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com