Efficient construction structure and method for micro steel pipe pile

A construction method and a technology of steel pipe piles, which are applied in foundation structure engineering, excavation, construction, etc., can solve problems such as drill sticking, pile pressing difficulties, and pile lengths that cannot meet the design requirements, and achieve the goal of increasing pile length and ensuring construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

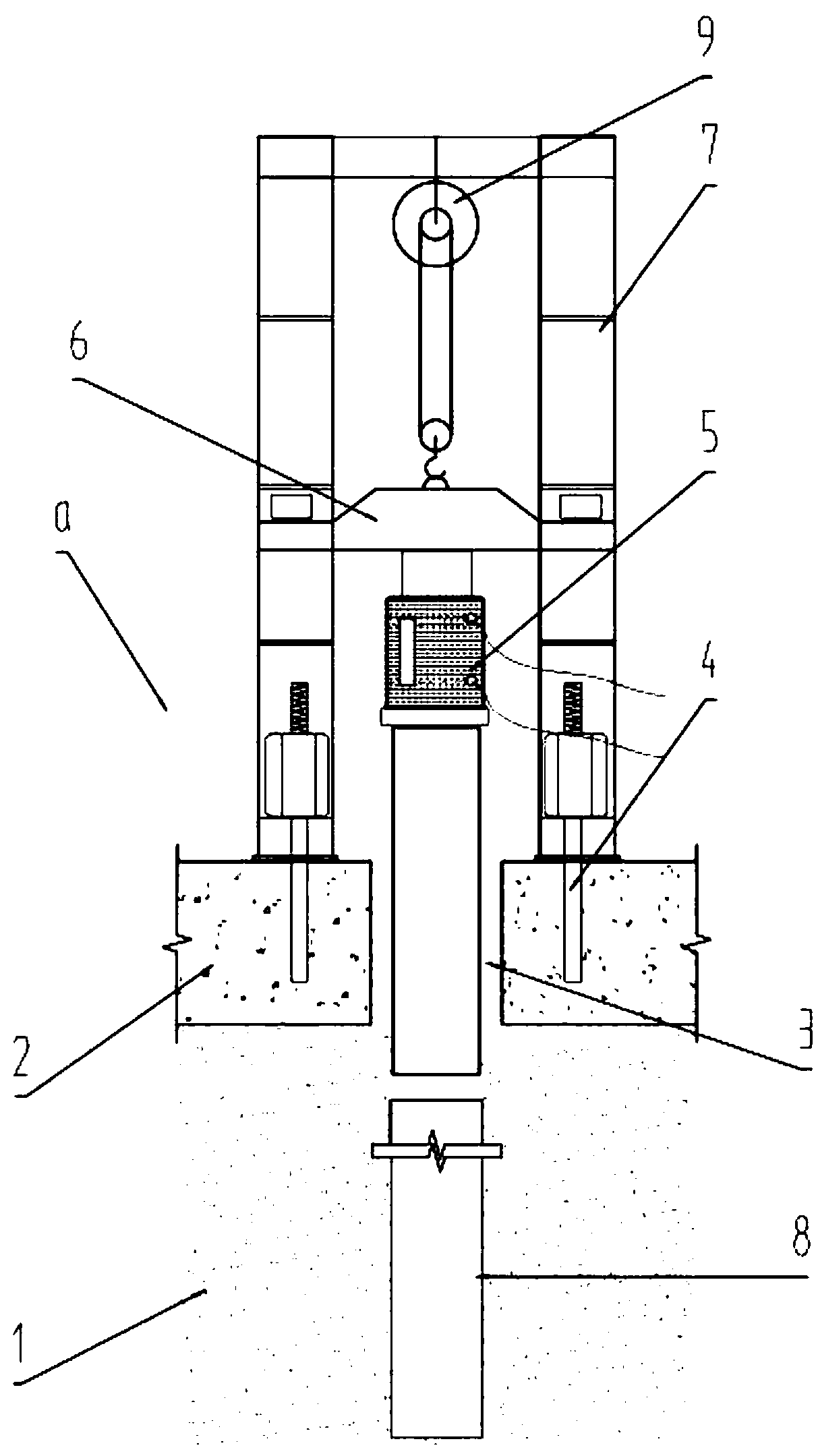

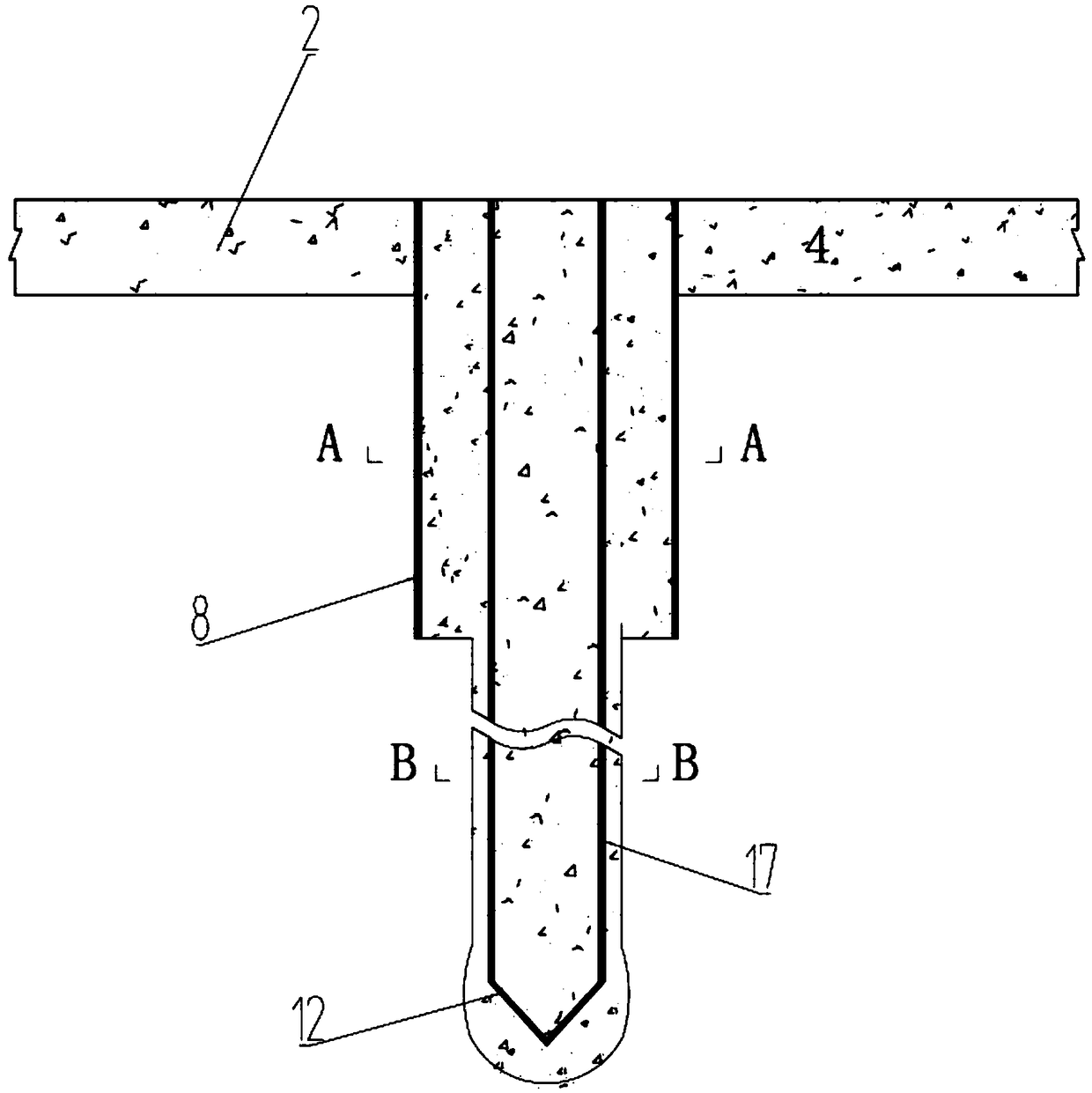

[0027] see Figure 1~5 , in the embodiment of the present invention, a high-efficiency micro-steel pipe pile construction structure includes a static anchor pile construction mechanism a and a steel pipe pile construction mechanism b. In this embodiment, in order to ensure the construction speed, the foundation, foundation pit and The side slope waits for the support position to carry out the construction of anchor static pressure piles, and then the construction of steel pipe piles. Due to the wall protection effect of anchor bolt static pressure piles, the drilling of steel pipe piles within the length of the anchor rod static pressure piles It will not be subject to the frictional resistance of the soil, which ensures the construction speed of the steel pipe pile, and can increase the pile length to ensure that the steel pipe pile reaches the bearing layer. It is especially suitable for loess areas or large-thickness fill areas.

[0028] Specifically, the anchor static pres...

Embodiment 2

[0032] see Figure 1~5 , a construction method for high-efficiency micro-steel pipe piles, comprising the following steps:

[0033] S1, first arrange the foundation at the soil around the pile, pre-embed anchor rods on the foundation, and reserve pile pressure holes between the foundations, and then install the reaction force frame and connect the anchor rods, that is, install the reaction force frame on the foundation;

[0034] S2. A steel pipe is implanted in the pressure pile hole, and a jack installed on the reaction frame is used to exert pressure on the steel pipe. When the current steel pipe is submerged in the soil around the pile, the next steel pipe is installed on the upper part of the current steel pipe through a spiral sleeve, and then passed through the jack. Apply pressure until the depth of the steel pipe submerged into the soil around the pile meets the design requirements or cannot be pressed down;

[0035] S3, then remove the reaction frame and jack, arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com