Method for relieving sill-lifting cavitation of suddenly-enlarged gallery for high-lift ship locks

A high water head and ship lock technology, applied in ship locks, ship lifting devices, buildings, etc., can solve problems such as affecting the safe operation of the ship lock, airbag explosion, affecting the water filling of the ship lock, etc., so as to shorten the sudden expansion of the corridor and reduce the cavitation of the lift. , Improve the effect of engineering safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

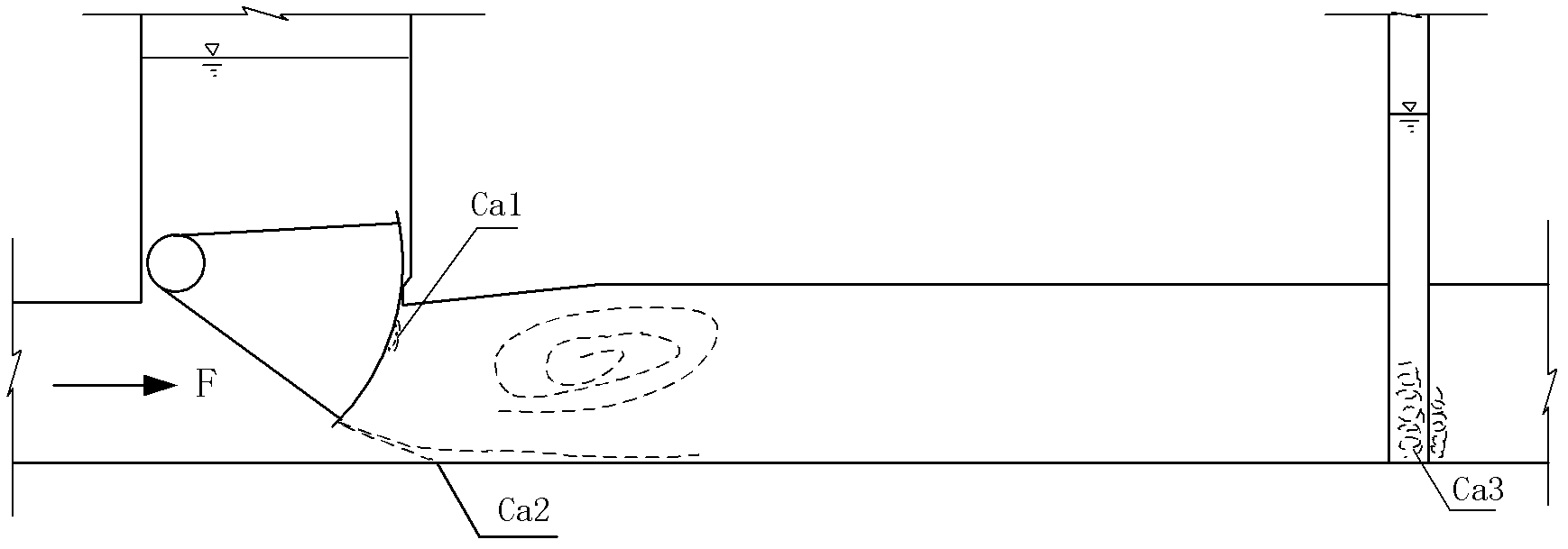

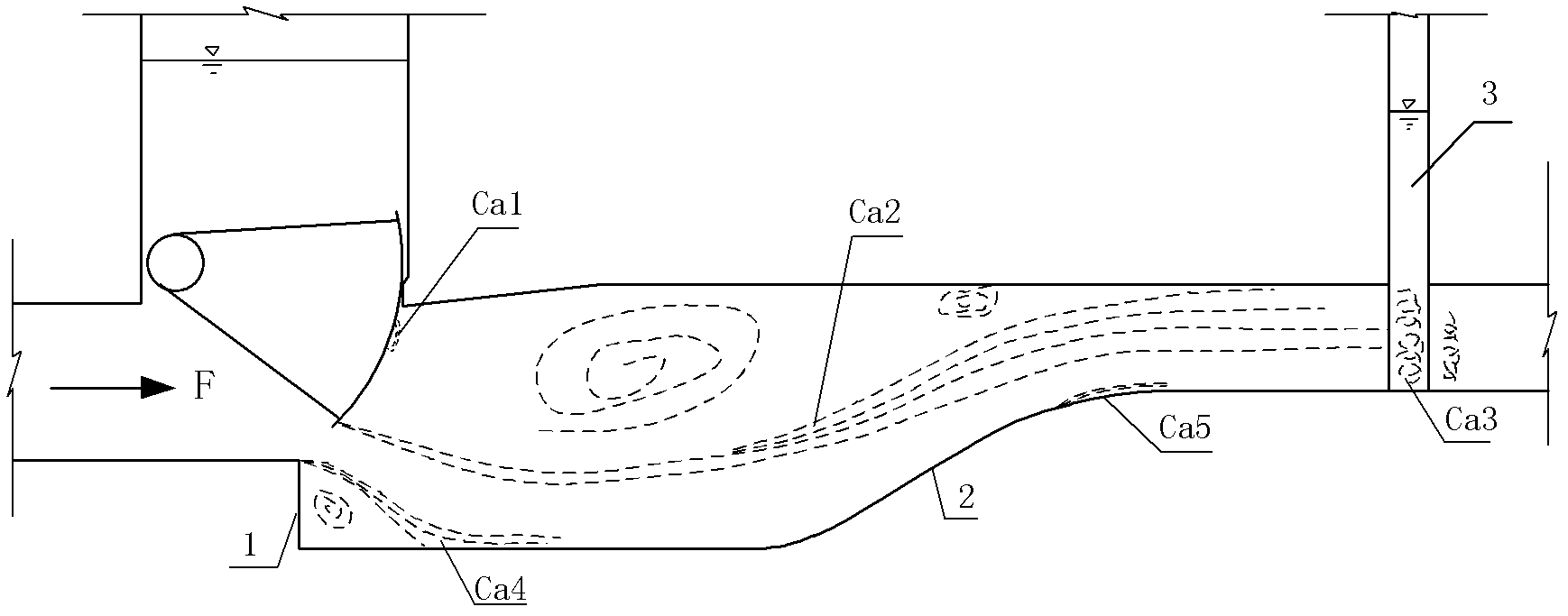

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a method for reducing the cavitation of the sudden expansion corridor of the high water head ship lock. Figure 4 It is the shape figure of the ship lock water delivery valve of the present embodiment, Figure 5 It is a large sample diagram of the rising sill aeration facility of this embodiment. Such as Figure 4 As shown, the rising sill 2 adopts a quintic curve-type sill, and the sill aeration facility 5 (in the form of a sill + aeration tank) is installed at the position where the water flow separates on the curved surface of the sill to form a stable low-pressure area. 4 is arranged on both sides of the aeration facility 5 of the ascending ridge, and aerates into the water flow. The ventilation pipe 4 leads to the top of the gate, and the way of ventilating into the water flow depends on the pressure in the aeration tank 5, such as the negative pressure in the aeration tank can suck enough air to make the cavitation zone of the cavitation zone ...

Embodiment 2

[0039] Figure 8 is the second embodiment of the present invention, Figure 9 It is a large sample diagram of the rising sill aeration facility of this embodiment. The ramp-up curve of this embodiment is the same as that of Embodiment 1, and a quintic curve is also used, the difference is that the ramp-up aeration facility is an aeration tank type. The sill 2 adopts a quintic curve-type sill, and the sill aeration facility 5 (in the form of an aeration tank) is installed at the position where the water flow separates on the curved surface of the sill to form a stable low-pressure area. The both sides of air facility 5, aerate in the water flow. The ventilation pipe 4 leads to the top of the gate, and the way of ventilating into the water flow depends on the pressure in the aeration tank 5, such as the negative pressure in the aeration tank can suck enough air to make the cavitation zone of the cavitation zone and the downstream aeration tank 3. When the aeration concentrati...

Embodiment 3

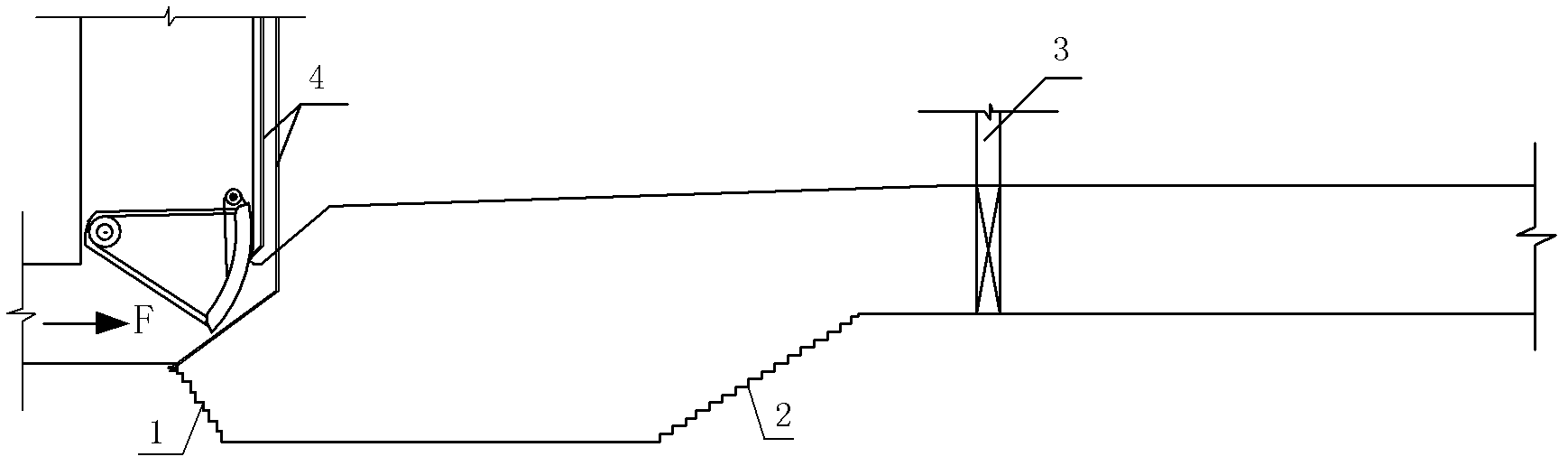

[0041] Figure 10 is the third embodiment of the present invention, Figure 11 It is a large sample diagram of the rising sill aeration facility of this embodiment. In this embodiment, both the falling slope and the rising slope curve adopt a step type, and the rising slope aeration facilities are in the form of aeration tanks. The sill 2 adopts a stepped sill, and the sill aeration facility 5 (aeration tank type) is installed at the position where the water flow is separated on the curved surface of the sill to form a stable low-pressure area. The ventilation pipe 4 is arranged on the aeration facility of the sill The two sides of 5, aerate in the water flow. The ventilation pipe 4 leads to the top of the gate, and the way of ventilating into the water flow depends on the pressure in the aeration tank 5, such as the negative pressure in the aeration tank can suck enough air to make the cavitation zone of the cavitation zone and the downstream aeration tank 3. When the aera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com