Drainage device

A technology of drainage device and lifting device, which is applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of ineffective discharge of chemicals, great influence on enterprise cost, and pollution of chemical components, and achieve easy installation, quality improvement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

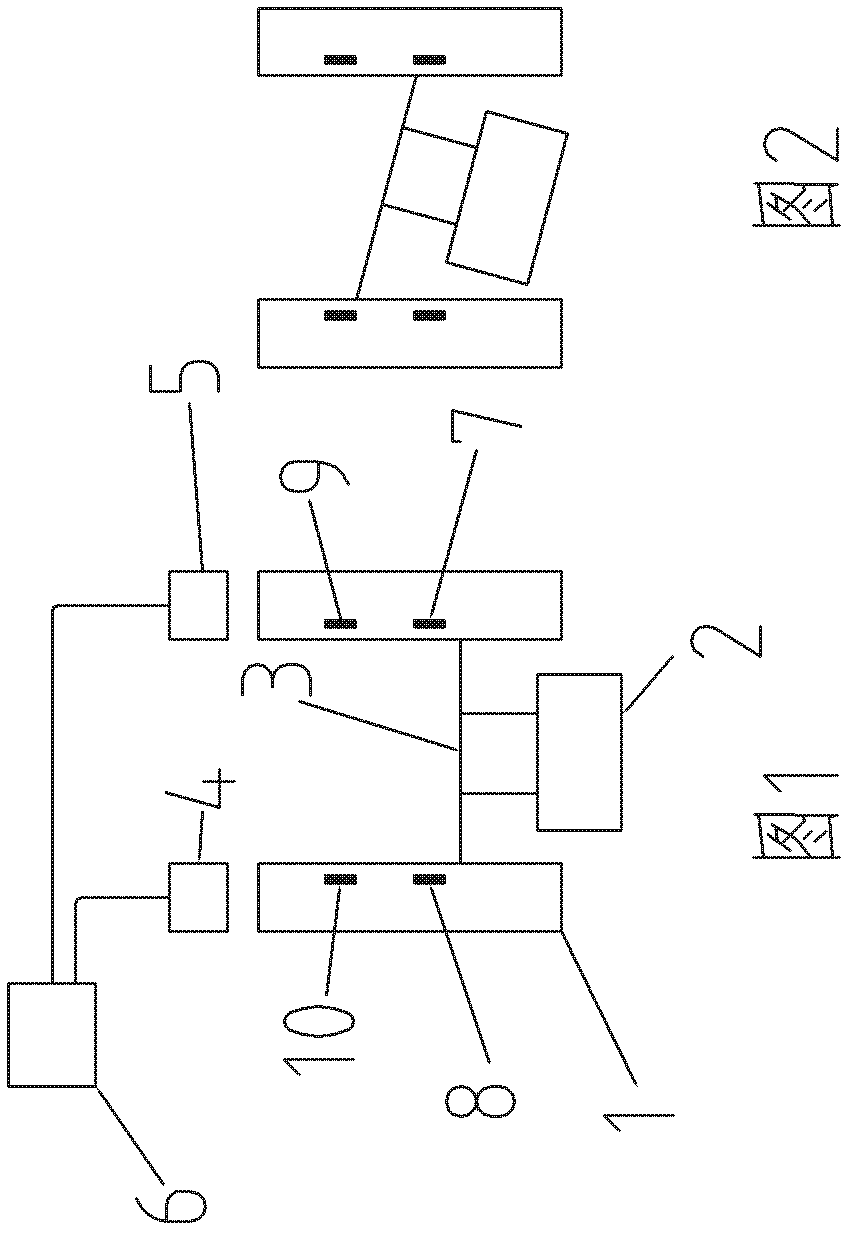

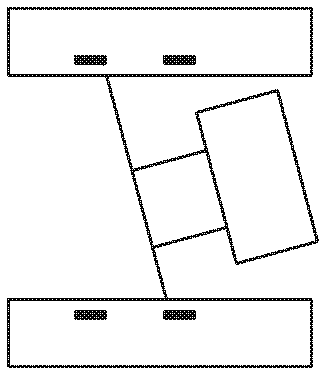

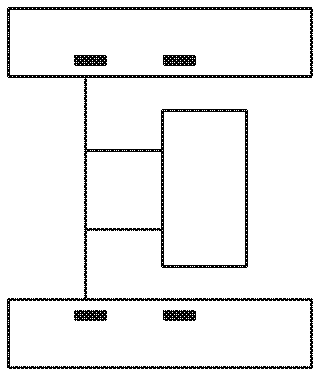

[0017] Such as figure 1 A drainage device shown includes a gantry lifting device body 1, a hanger 2 and a hanger connecting rod 3, the hanger 2 is arranged below the hanger connecting rod 3, and the gantry lifting device body 1 is respectively provided with an independent drive The left motor 4 and the right motor 5, the left motor 4 is connected with the left end of the hanger connecting rod 3 by a chain rope and can drive the left end of the hanger connecting rod 3 to lift, and the right motor 5 is connected with the right end of the hanger connecting rod 3 by a chain rope and can Drive the right end of the hanger connecting rod 3 to go up and down, and the left motor 4 and the right motor 5 are connected with the control unit.

[0018] In this embodiment, the control unit is a PLC controller 6 . The left gantry lifting column of the gantry lifting device body 1 is provided with two upper and lower positioning sensors 8, 10 for detecting the position of the left end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com