Environment-friendly sheath material for cable and preparation method thereof

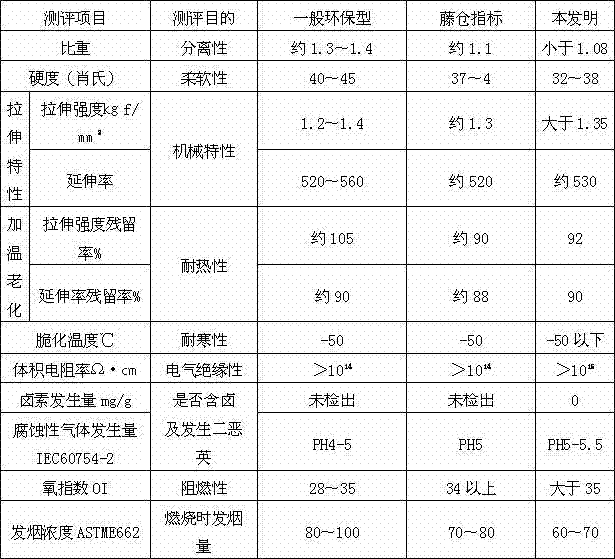

An environmentally friendly technology for cable sheathing materials, applied in the direction of insulating cables, cables, circuits, etc., to achieve the effects of easy separation, improved printing and identification, and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The components in the formula: 100 parts of POE, 2.5 parts of DCP, 2 parts of TAIC, 1.5 parts of antioxidant 1010, 15 parts of special fumed silica (Germany Degussa R300 type), compound modification of flame retardant synergist 50 parts of high-strength nano-kaolin (S-580 type of Shandong Zaozhuang Sanxing High-tech Material Co., Ltd.), 10 parts of epoxy ethyl soybean oil, 30 parts of nano-magnesium hydroxide flame retardant (Dalian Fumeida New Material Technology Co., Ltd.), 5 parts of silicone flame retardant (Japan Shin-Etsu Chemical Co., Ltd. FRX-210 type), 3 parts of composite stabilizer calcium / zinc (Hangzhou Longshang Chemical Co., Ltd. CZ-3390 type), 3 parts of MV (Shanghai Rizhisheng New Technology Development Co., Ltd., model 0106), 5 parts of zinc oxide, and 0.5 parts of coupling agent (Si69 Jiangsu Aiteen Polymer Material Co., Ltd.).

[0021] The preparation steps are: according to the mass parts of the formula, POE, epoxy ethyl soybean oleate, composite st...

Embodiment 2

[0023] The components in the formula: 100 parts of POE, 3.5 parts of DCP, 2 parts of TAIC, 2.5 parts of antioxidant 1010, 25 parts of special fumed silica (Germany Degussa R300 type), compound modification of flame retardant synergist 45 parts of high-strength nano-kaolin (S-580 type of Shandong Zaozhuang Sanxing High-tech Material Co., Ltd.), 25 parts of epoxy ethyl soybean oil, 40 parts of nano-magnesium hydroxide flame retardant (Dalian Fumeida New Material Technology Co., Ltd.), 10 parts of silicone flame retardant (Japan Shin-Etsu Chemical Co., Ltd. FRX-210 type), 7 parts of composite stabilizer calcium / zinc (Hangzhou Longshang Chemical Co., Ltd. CZ-3390 type), 7 parts of MV (Shanghai Rizhisheng New Technology Development Co., Ltd., model 0106), 7 parts of zinc oxide, and 1.5 parts of coupling agent (Si69 Jiangsu Aiten Polymer Material Co., Ltd.).

[0024] The preparation steps are the same as above.

Embodiment 3

[0026] The components in the formula: 100 parts of POE, 3 parts of DCP, 2.5 parts of TAIC, 2 parts of antioxidant 1010, 20 parts of special fumed silica (Germany Degussa R300 type), compound modified flame retardant synergist 40 parts of high-strength nano-kaolin (S-580 type of Shandong Zaozhuang Sanxing High-tech Material Co., Ltd.), 20 parts of epoxy ethyl soybean oleate, 35 parts of nano-magnesium hydroxide flame retardant (Dalian Fumeida New Material Technology Co., Ltd.), 8 parts of organic silicon flame retardant (Japan Shin-Etsu Chemical Co., Ltd. FRX-210 type), 5 parts of composite stabilizer calcium / zinc (Hangzhou Longshang Chemical Co., Ltd. CZ-3390 type), 5 parts of MV (Shanghai Rizhisheng New Technology Development Co., Ltd., model 0106), 6 parts of zinc oxide, and 1 part of coupling agent (Si69, Jiangsu Aiteen Polymer Material Co., Ltd.).

[0027] The preparation steps are the same as above.

[0028] Each component is described below:

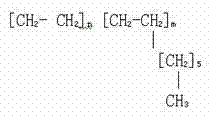

[0029] POE is a new type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com