Metallocene polyethylene greenhouse film resin composition with high intensity and ultra-broad width, and its preparation method

A technology of metallocene polyethylene and resin composition, applied in the field of ultra-wide shed film resin composition and preparation thereof, can solve the problems of high tear strength, limited amplitude and the like, achieve improved melt strength, improved cost and effect significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

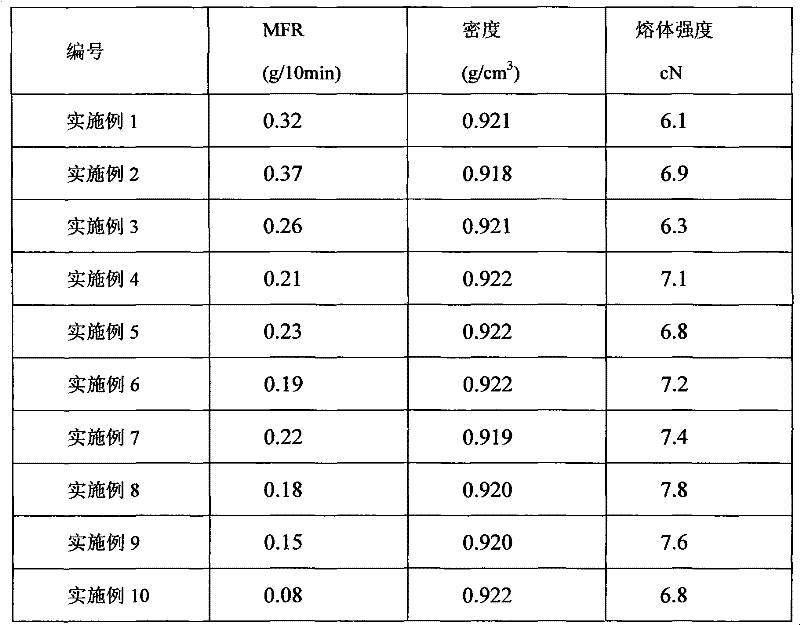

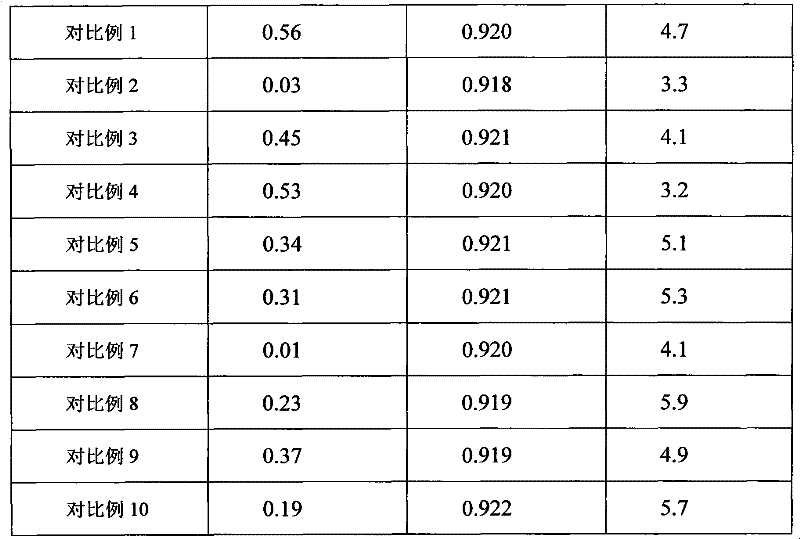

Examples

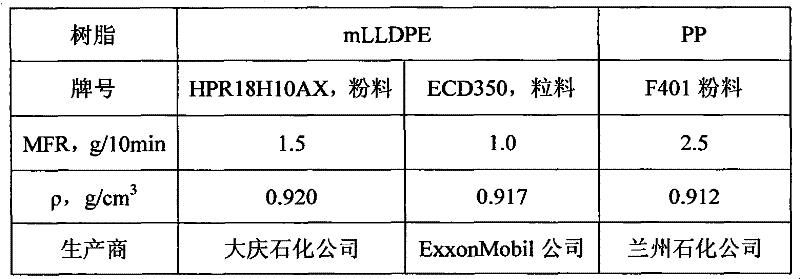

Embodiment 1

[0054] (1) Preparation of PP / mLLDPE blended graft a: Take 0.04 parts of DCP and 0.15 parts of acetone and mix them in a beaker, then mix the mixed solution with 80 parts of PP (F401) and 20 parts of mLLDPE (HPR18H10AX) , 4 parts of methacrylic acid mixed together at high speed for 5 minutes, then put the mixed material into a twin-screw extruder for melt grafting reaction, the reaction temperature is 170-220 ° C, the reaction time is 7 minutes, extrusion, cooling, granulation, The PP / mLLDPE blended graft a was obtained.

[0055] (2) Preparation of mLLDPE greenhouse film resin composition: After mixing 0.33 parts of TB and 0.025 parts of TBPA with 0.8 parts of acetone solvent, then add 5 parts of mLLDPE (HPR18H10AX) and 0.15 parts of antioxidant 1010, 0.15 parts of calcium stearate , After mixing in a 10-liter high-speed mixer for 3 minutes, a premixed masterbatch was made. Take out 13 parts of PP / mLLDPE blended graft a, premixed masterbatch and 95 parts of mLLDPE (HPR18H10AX)...

Embodiment 2

[0057] (1) Preparation of PP / mLLDPE blended graft b: Take 0.07 parts of DCP and 0.2 parts of acetone and mix them in a beaker, then mix the mixed solution with 70 parts of PP (F401) and 30 parts of mLLDPE (ECD350) , 7 parts of methacrylic acid mixed together at high speed for 5 minutes, then put the mixed material into a twin-screw extruder for melt grafting reaction, the reaction temperature is 170-220 ° C, the reaction time is 7 minutes, extrusion, cooling, granulation, The PP / mLLDPE blended graft b was obtained.

[0058] (2) Preparation of mLLDPE greenhouse film resin composition: After mixing 0.29 parts of TB and 0.03 parts of TBPA with 0.7 parts of xylene solvent, then add 5 parts of mLLDPE (ECD350) and 0.2 parts of antioxidant 1010, 0.2 parts of stearic acid Zinc, mixed in a 10-liter high-speed mixer for 3 minutes, was made into a premixed masterbatch. Take out 17 parts of PP / mLLDPE blended graft b, premixed masterbatch and 95 parts of mLLDPE (ECD350) and add them to th...

Embodiment 3

[0060] (1) Preparation of PP / mLLDPE blended graft c: Take 0.06 parts of BPDH and 0.22 parts of acetone and mix them in a beaker, then mix the mixed solution with 75 parts of PP (F401), 25 parts of mLLDPE (HPR18H10AX ), 6 parts of butyl methacrylate were mixed at high speed for 5 minutes, and then the mixed material was added to a twin-screw extruder for melt grafting reaction. The reaction temperature was 170-220 ° C, and the reaction time was 7 minutes. Extrusion, cooling, Granulate to obtain PP / mLLDPE blended graft c.

[0061] (2) Preparation of mLLDPE greenhouse film resin composition: After mixing 0.26 parts of TB and 0.08 parts of TBPA with 0.9 parts of acetone solvent, then add 8 parts of mLLDPE (HPR18H10AX) and 0.2 parts of antioxidant 1010, 0.2 parts of zinc stearate , After mixing in a 10-liter high-speed mixer for 3 minutes, a premixed masterbatch was made. Take out 20 parts of PP / mLLDPE blended graft c, premixed masterbatch and 92 parts of mLLDPE (HPR18H10AX) and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com