Preparation method of temperature-sensitive macroporous acrylamide/N-isopropyl acrylamide composite microsphere

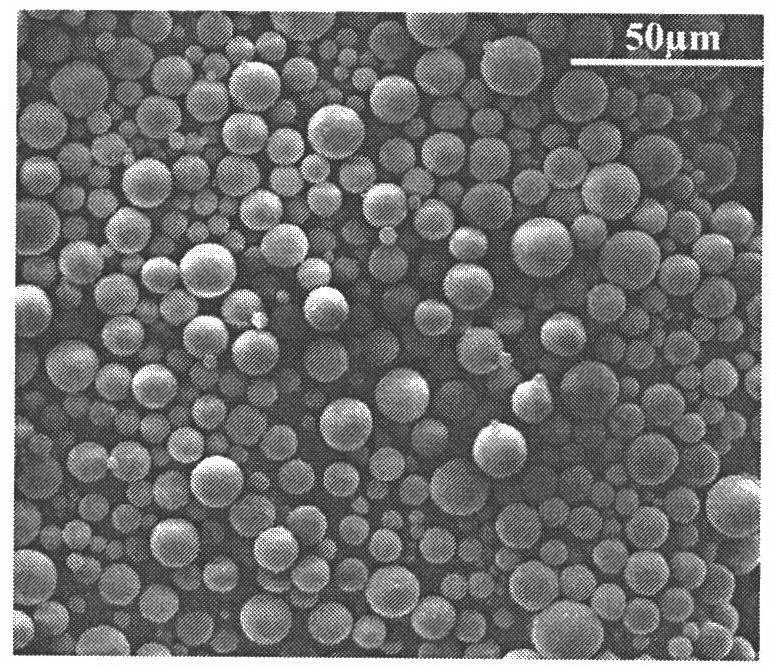

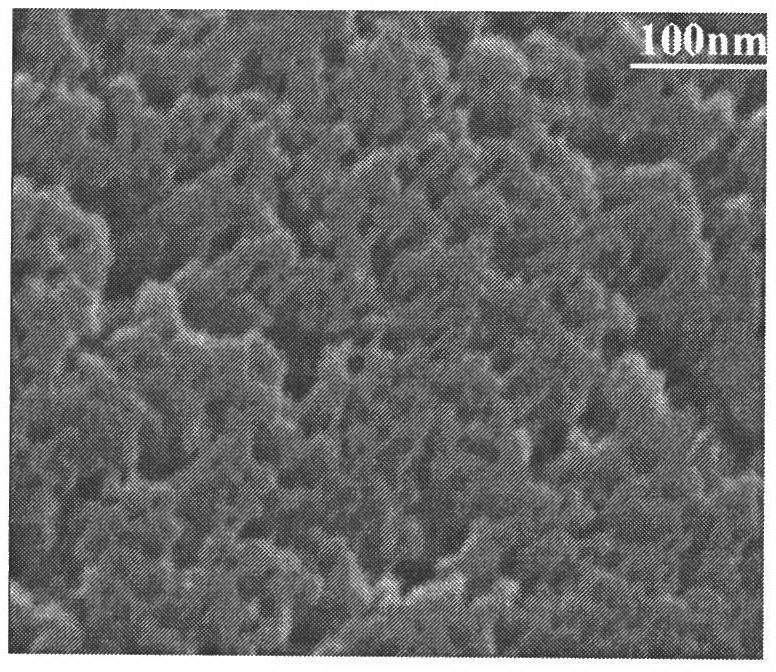

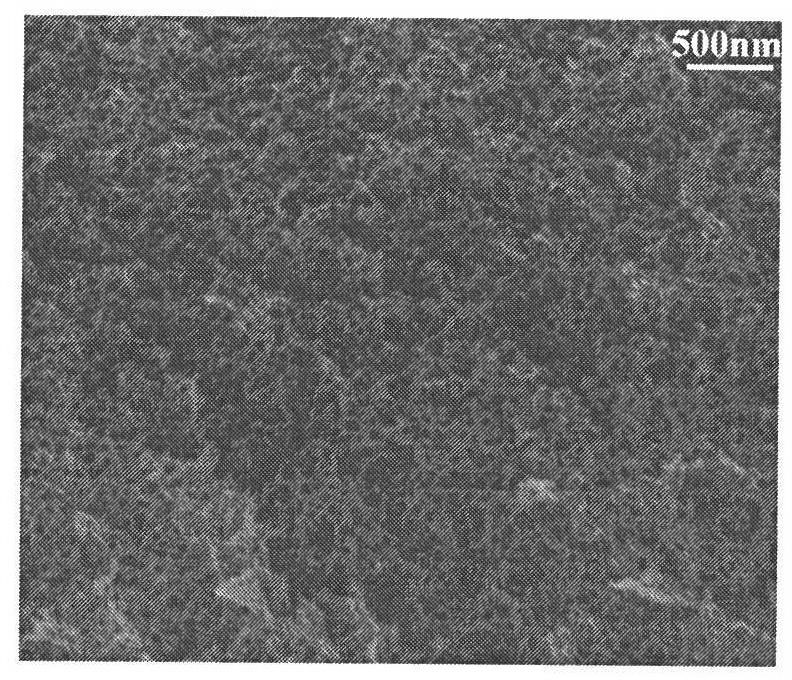

A technology of isopropyl acrylamide and acrylamide, applied in the field of materials, can solve the problems of poor performance of immobilized enzymes, poor biocompatibility, shrinkage and deformation, etc., and achieve obvious macroporous structure and temperature sensitivity, The pore size is uniform and dense, and the effect of strong water absorption and adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of water phase

[0028] Add 1.0g of acrylamide, 4.0g of N-isopropylacrylamide, 0.40g of ammonium persulfate, and 1.0g of N,N'-methylenebisacrylamide into 25g of deionized water, and acrylamide and N-isopropylacrylamide The mass ratio of amide, ammonium persulfate, N, N'-methylenebisacrylamide, and deionized water is 1:4:0.4:1.0:25, stirred until the solid is completely dissolved, and prepared into 31.4 g of the water phase.

[0029] 2. Preparation of oil phase

[0030] Put 90g of cyclohexane in a 250mL three-necked flask equipped with a stirrer, add 0.1g of Span-60 and 0.5g of Span-80, and the mass ratio of Span-60 to Span-80 and cyclohexane is 1 : 5: 900, stir at room temperature until Span-60 and Span-80 are completely dissolved, and prepare 90.6 g of oil phase.

[0031] 3. Preparation of thermosensitive macroporous acrylamide / N-isopropylacrylamide composite microspheres

[0032] Get the aqueous phase 30g that step 1 prepares, add toluene 2g, mix uni...

Embodiment 2

[0044] In step 1 of preparing the water phase in Example 1, 1.0 g of acrylamide, 3.0 g of N-isopropylacrylamide, 0.5 g of ammonium persulfate, and 0.5 g of N, N'-methylenebisacrylamide were added to 25 g to remove In ionized water, the mass ratio of acrylamide to N-isopropylacrylamide, ammonium persulfate, N,N'-methylenebisacrylamide, and deionized water is 1:3:0.5:0.5:25, and stirred until solid Dissolve completely and prepare 30g of water phase. The other steps were the same as in Example 1 to prepare thermosensitive macroporous acrylamide / N-isopropylacrylamide composite microspheres.

Embodiment 3

[0046] In step 1 of preparing the water phase in Example 1, 1.0 g of acrylamide, 5.0 g of N-isopropylacrylamide, 0.25 g of ammonium persulfate, and 2.0 g of N, N'-methylenebisacrylamide were added to 25 g to remove In ionized water, the mass ratio of acrylamide to N-isopropylacrylamide, ammonium persulfate, N,N'-methylenebisacrylamide, and deionized water is 1:5:0.25:2.0:25, and stirred until solid Dissolve completely, and prepare 33.25g of water phase. The other steps were the same as in Example 1 to prepare thermosensitive macroporous acrylamide / N-isopropylacrylamide composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com