High-performance concrete capable of resisting high-temperature cracking

A high-performance concrete, high-efficiency technology, applied in the field of building materials, can solve problems such as poor anti-burst performance, and achieve the effects of no noise pollution, cost reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: High performance concrete HPCPF1-C30 resistant to high temperature bursting

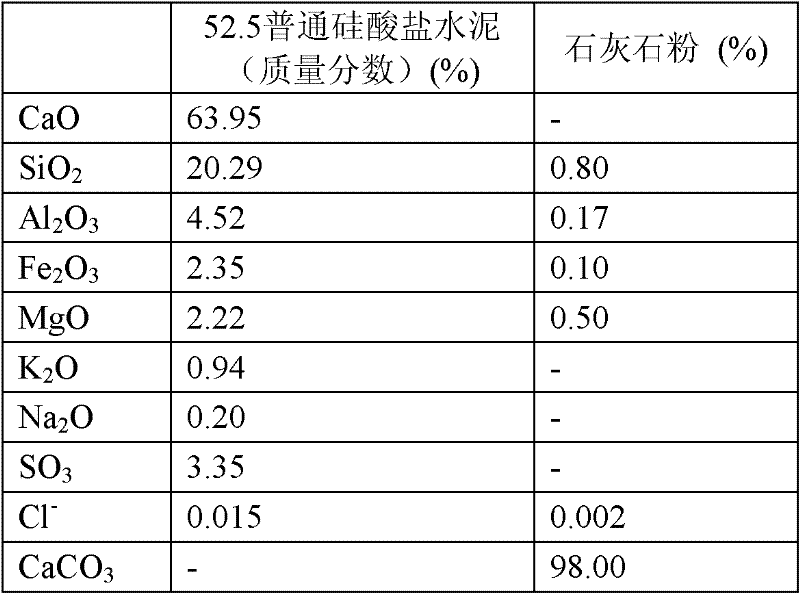

[0017] The mix ratio of concrete HPCPF1-C30 is shown in Table 1, and the parameters of the material polypropylene fiber and limestone powder are shown in Table 4 and Table 5.

[0018] Table 1 The mix ratio of high-performance concrete HPCPF1-C30 resistant to high temperature bursting

[0019] ingredients

Embodiment 2

[0020] Example 2: High performance concrete HPCPPF1-C60 resistant to high temperature bursting

[0021] Table 2 Proportion of high-performance concrete HPCPPF1-C60 resistant to high temperature bursting

[0022] ingredients

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com