High-speed paper-transferring device

A high-speed, paper-pressing technology, which is applied in the field of high-speed paper transfer device, hot stamping machine or die-cutting machine, can solve the problems of high-speed equipment, high impact force and fast wear of the paper transfer device, and achieve optimization The effect of high motion and paper delivery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

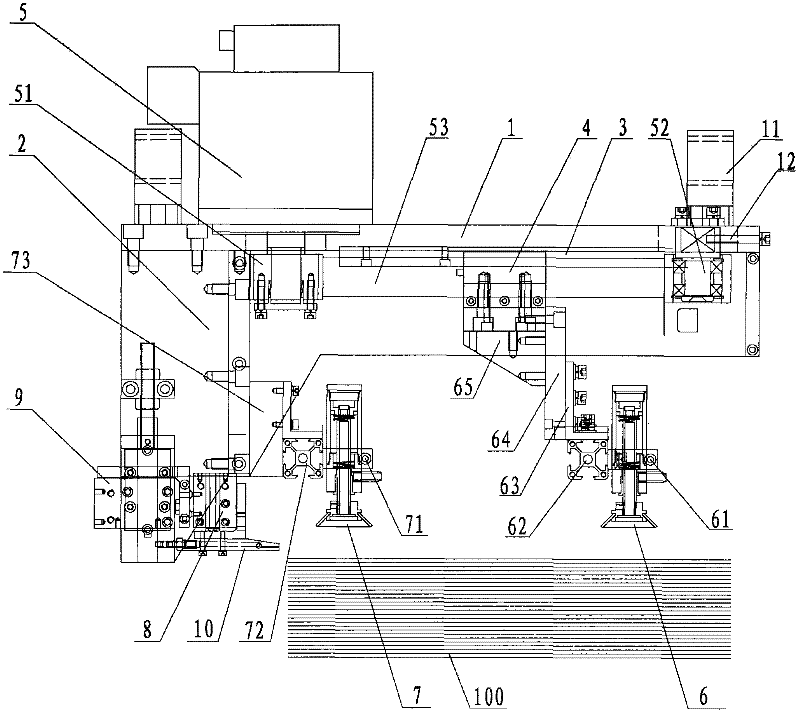

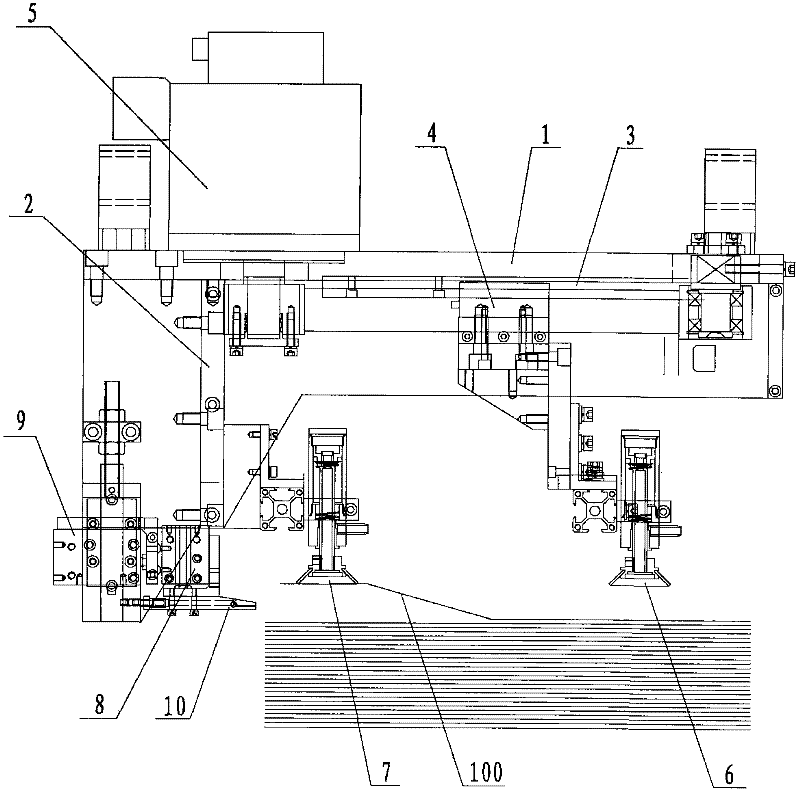

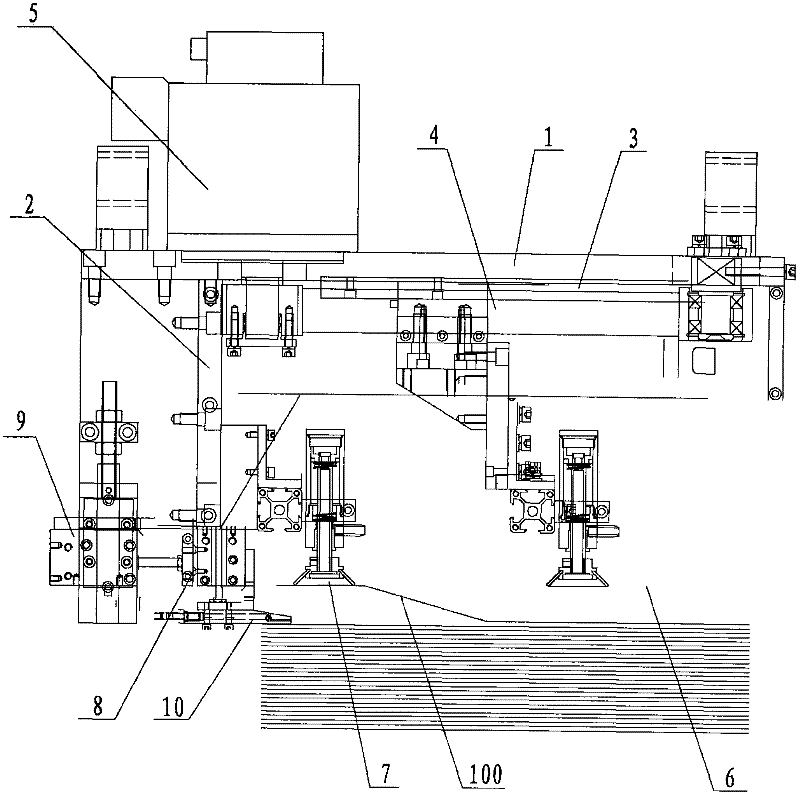

[0016] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a high-speed paper transfer device, which consists of an upper fixed plate 1, a support plate 2, a linear guide rail 3, a slider 4, a servo motor 5, a first paper suction nozzle combination 6, and a second paper suction nozzle combination 7. It is composed of horizontal sliding table cylinder 8, vertical sliding table cylinder 9 and paper presser foot 10 and other components.

[0017] Wherein, the linear guide rail 3 and the servo motor 5 are installed on the upper fixed plate 1 , and the support plate 2 is located below the upper fixed plate 2 . Further, a pair of lifting lugs 11 are also provided on the upper fixing plate 1, so as to facilitate the lifting of the paper delivery device.

[0018] The servo motor 5 drives the slider 4 through a timing pulley 51 , a tension pulley 52 and a timing belt 53 . A tension adjustment screw 12 is further provided at one end of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com