Air-water backwash filter and air-water backwash method

A technology of backwashing and filter tanks, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of small effective filtration area, low degree of automation, high installation precision requirements, etc., achieve good water quality after filtration, improve filtration Efficiency, quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

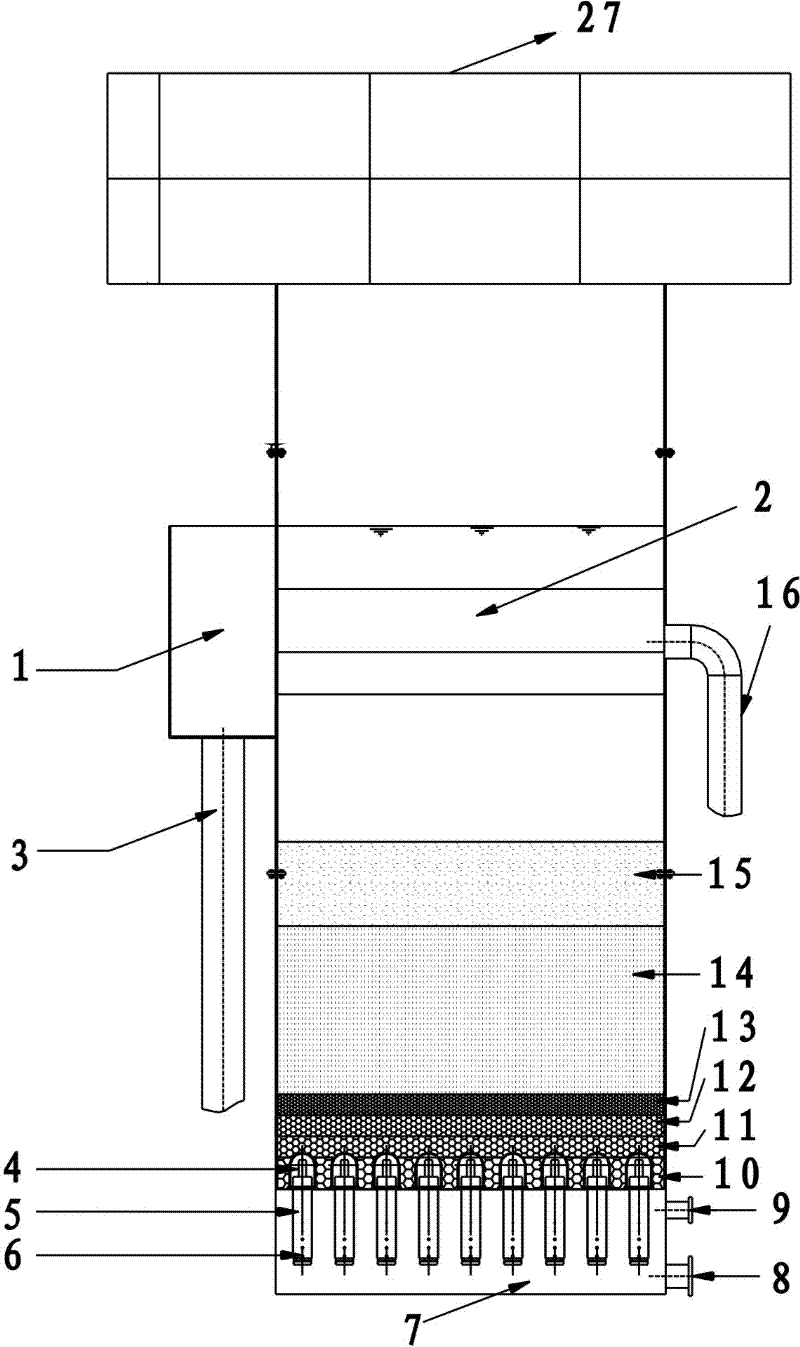

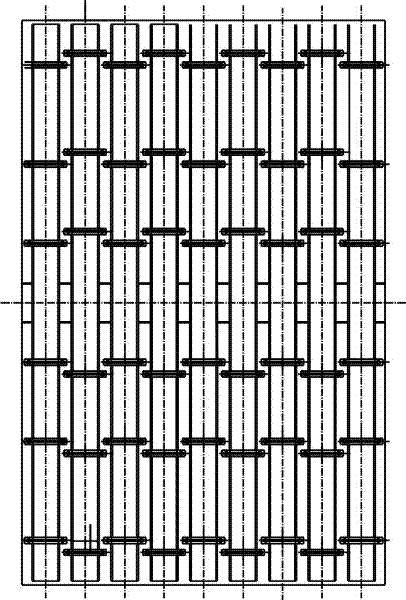

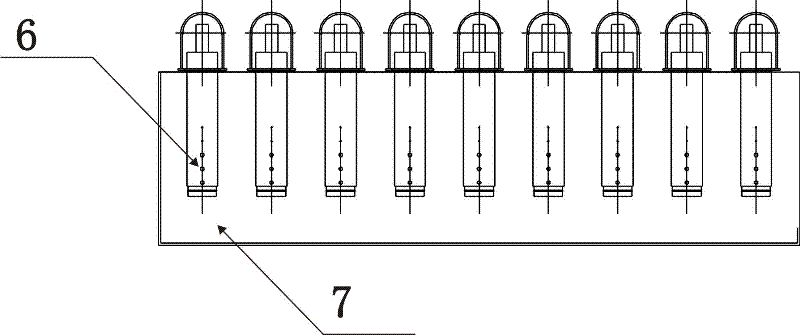

[0027] The invention provides an air-water backwashing filter tank, the purpose of which is to overcome the complex structure of the existing filter tank, high installation precision requirements, large civil construction costs, short filtration cycle, high operating costs, poor water quality after filtration, and low automation. Not high enough. The new filter fully absorbs the advantages of V-shaped filter, ordinary fast filter and flap filter, and is a hybrid high-efficiency filter. Such as Figure 1-4 As shown: the present invention includes an air-water collection and distribution horizontal pipe 4 and an air-water collection and distribution vertical pipe 5 installed at the bottom of the filter tank for filtering water collection and backwashing water distribution, and a safety guardrail 27 is provided at the upper end of the filter tank. The air-water collection and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com