Preparation method of particle defoaming agent

一种消泡剂、颗粒的技术,应用在制备颗粒消泡剂领域,能够解决硅脂难均匀分布、泡沫控制效果不太理想、很难保证产品消泡稳定性等问题,达到提高连续消泡稳定性、保证品质均一性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

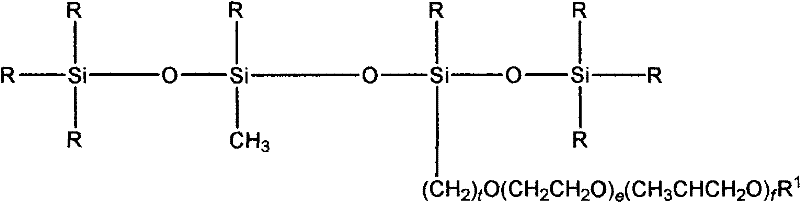

[0039] (1) Preparation of silicone emulsion S1:

[0040] At room temperature, add 20 parts of G1, 1.5 parts of Pingpingjia O-25, 0.5 parts of sorbitan monooleate, 3 parts of silicon polyether E 2 , 3 parts of silicon polyether E 1 Raise the temperature to 70°C while stirring, fully emulsify and mix for 35 minutes; after completion, keep the temperature of the system at 70°C and slowly add water, increase the stirring speed to change the phase from water-in-oil emulsion to oil-in-water emulsion, and continue to add water To the required mass concentration, it is 50%. The above mixture is further emulsified by a colloid mill to obtain the desired silicone emulsion S1.

[0041] (2) Preparation of silicone emulsion S2:

[0042] At room temperature, add 30 parts of G2, 4.5 parts of Pingpingjia O-15, 3 parts of sorbitan monooleate, 2.5 parts of silicon polyether E 1 , 4 parts of silicon polyether E 3 , raise the temperature to 80°C while stirring, and mix thoroughly at 80°C for...

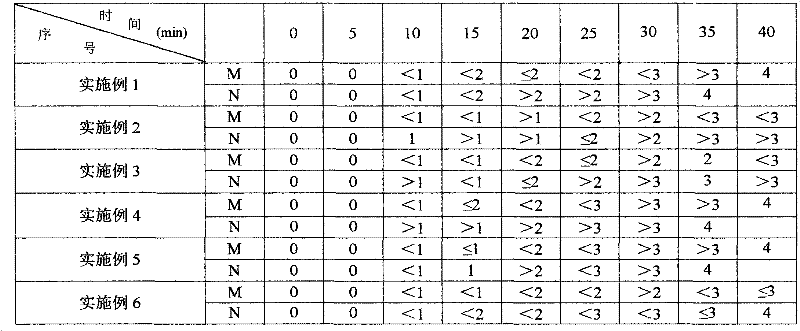

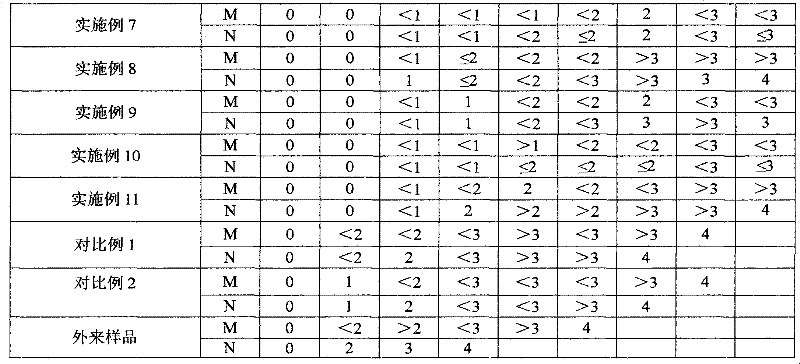

Embodiment 1

[0051] Add 70g of starch into the mixer, add 12.5g of silicone emulsion S2 into it, and stir evenly; add 5g of starch into it, stir evenly, then add 2.5g of silicone emulsion S4, and stir evenly. Then add 2g sodium carboxymethylcellulose and 3g polyacrylic acid, continue to stir, add 5g of absolute ethanol after stirring evenly, granulate and dry the mixture obtained after stirring evenly, and obtain the prepared granular defoamer Example 1 .

Embodiment 2

[0053] Add 60g of sodium sulfate (800 mesh) into the mixer, add 16.5g of silicone emulsion S2 to it, and stir evenly; then add 9g of sodium sulfate (800 mesh), stir evenly, and then add 3.5g of silicone emulsion S5, Stir well. Then add 2g of sodium citrate and 3g of maleic acid acrylic acid copolymer, continue to stir, add 3g of absolute ethanol and 3g of deionized water after stirring evenly, granulate and dry the obtained mixture after stirring evenly, and obtain the prepared granules Defoamer Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com