Stator or rotor punching mould of power generator

A technology for rotor punching and generator, applied in the field of punching die, can solve problems such as difficulty in ensuring precision requirements, inability to guarantee die quality, increase processing cost, etc., and achieve the effect of saving material cost, reducing deformation and increasing processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

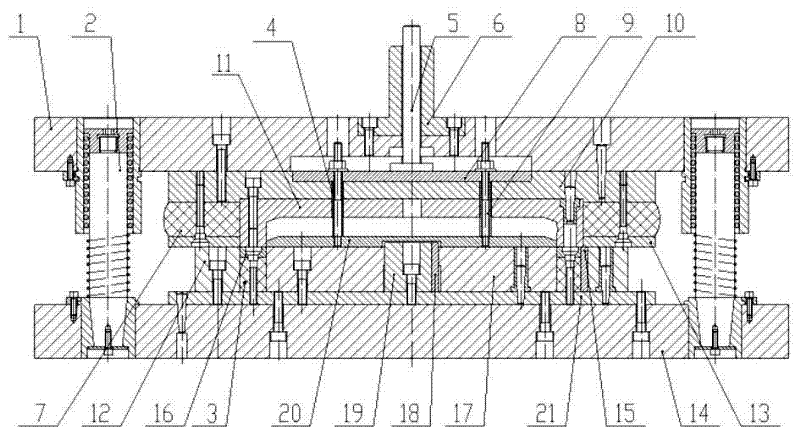

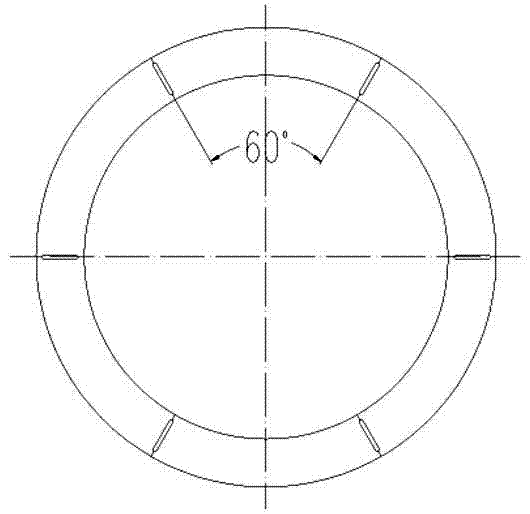

[0016] Such as figure 1 As shown, the generator stator and rotor stamping dies of the present invention include upper and lower mold bases 1, 14, and multiple sets of rolling guides that are evenly distributed and vertically arranged between the upper and lower mold bases 1, 14. Assembly 2, and the upper mold assembly fixed on the lower surface of the upper mold base 1 and the lower mold assembly on the upper surface of the lower mold base 14; the lower mold assembly is respectively fixed on the lower backing plate 21 by the lower backing plate 21 The annular stator die 12, the annular elastic rubber block 3 set in the annular stator die 12, the annular stator stripper plate 16 fixed on the upper ring surface of the annular elastic rubber block 3, and the ring-shaped elastic rubber block 3 located in the The rotor punch 17 is composed of a positioning shaft 19 through a positioning key 18 at the center of the rotor punch 17 for the positioning of the rotor stripping plate 20; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com