Automatic gear-shifting wheel-hub motor of electric vehicle

A technology of automatic variable speed and wheel hub motors, which is applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of small adaptability, poor climbing ability and overload capacity, and large output torque, and achieve simple and compact structure and improve climbing The effect of large capacity and transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

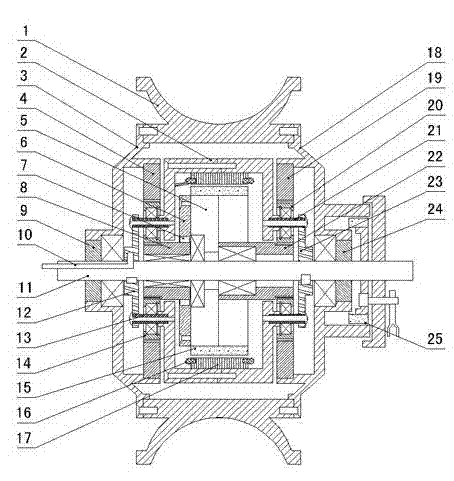

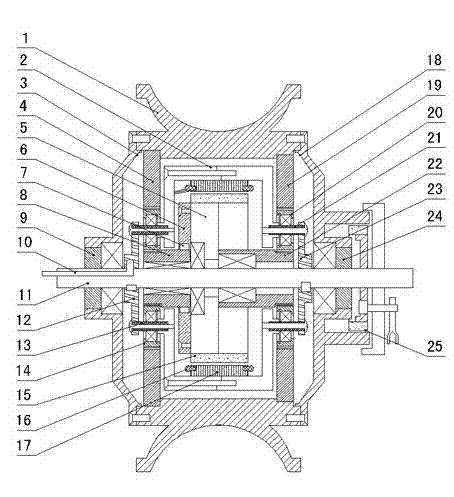

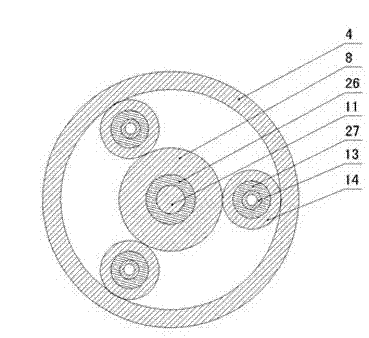

[0020] figure 1 , image 3 and Figure 4 As shown, the present invention creates the first specific embodiment of the automatic variable speed wheel hub motor for electric vehicles, which includes the hub 1, the left and right end covers 3, 18, the main shaft 11, the motor, and the left and right end covers 3, 18 and the wheel hub 1 form an airtight shell The outer shell is rotatably arranged on the main shaft 11 through the bearings arranged on the left and right end covers 3, 18, and the motor is installed in the outer shell. The motor includes an inner shell 2, an automatic clutch 5, a rotor magnet 15, The stator coil 16, the stator iron core 17, the automatic clutch 5 are rotatably installed on the main shaft 11 through the bearing, the rotor magnetic steel 15 is evenly distributed on the outer shell circumference of the automatic clutch 5, the stator iron core 17 is fixed on the rotor magnetic steel 15 On the corresponding inner casing 2 , the stator coil 16 is embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com