Thin-film solar photovoltaic cell module

A technology of solar cells and solar panels, applied in photovoltaic modules, circuits, photovoltaic power generation, etc., can solve the problems of troublesome connection, unsightly, time-consuming, etc., and achieve the effect of reducing long-term service life and keeping the back and side simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Various preferred embodiments of the present application are described below with reference to the accompanying drawings.

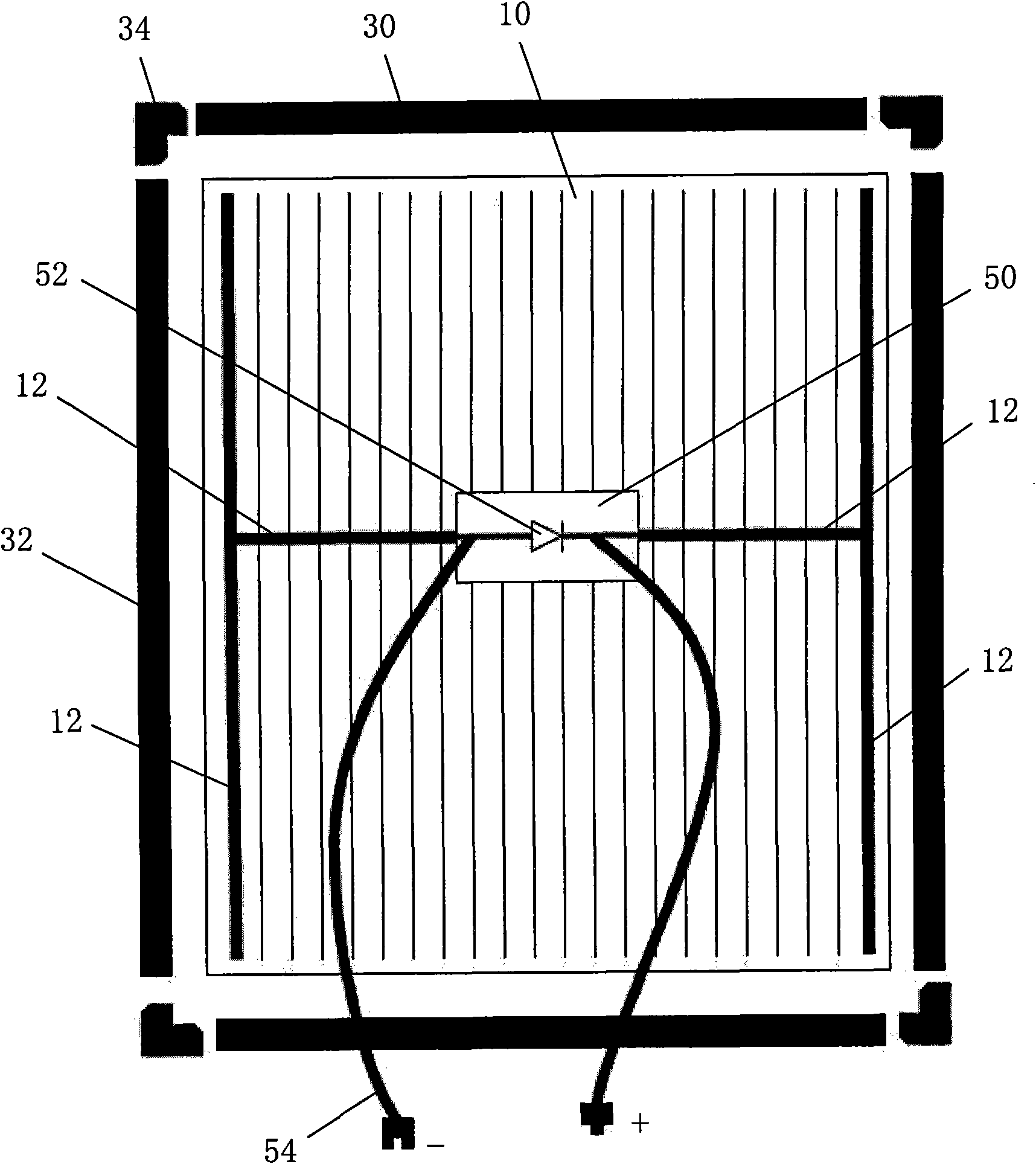

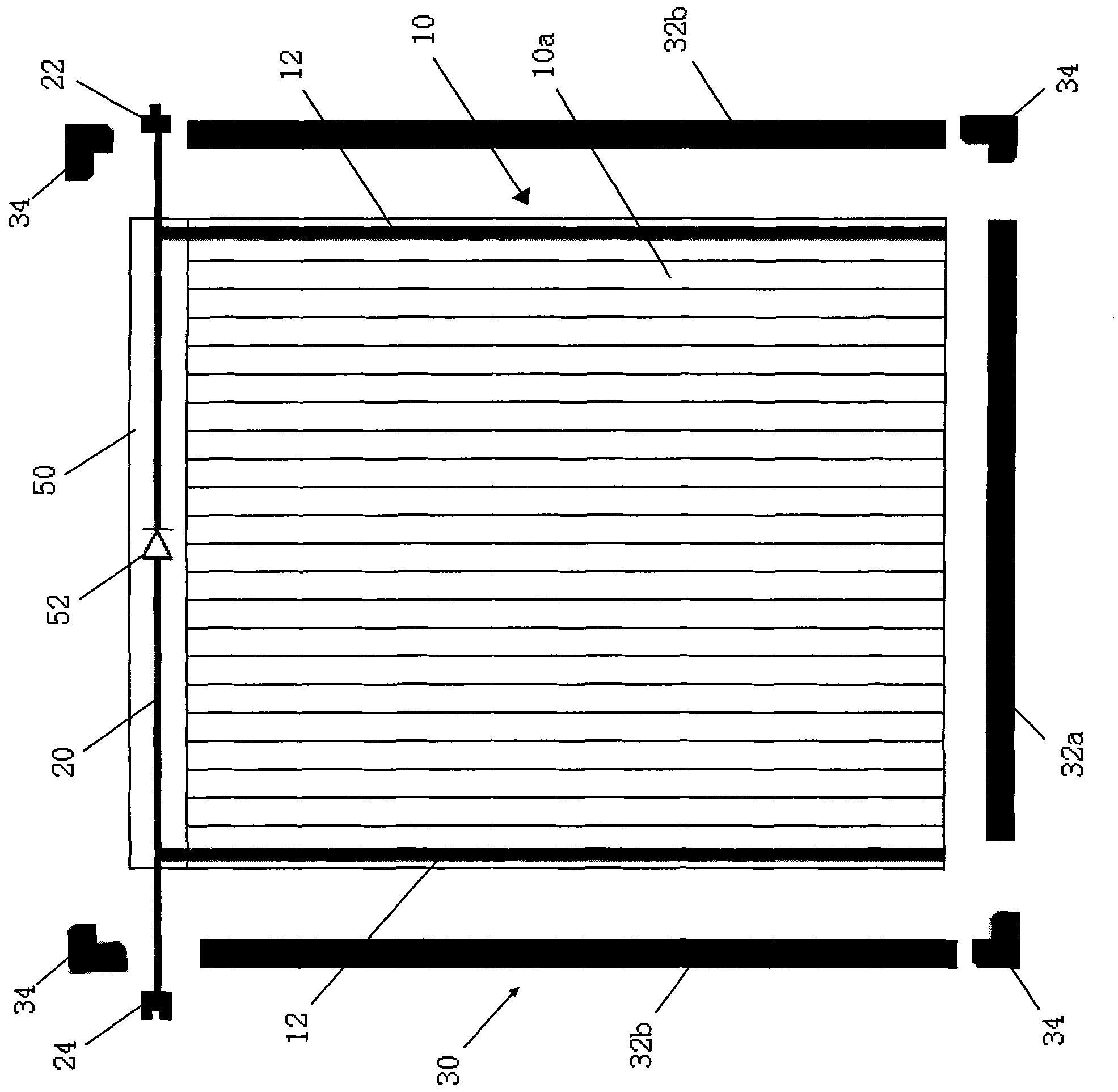

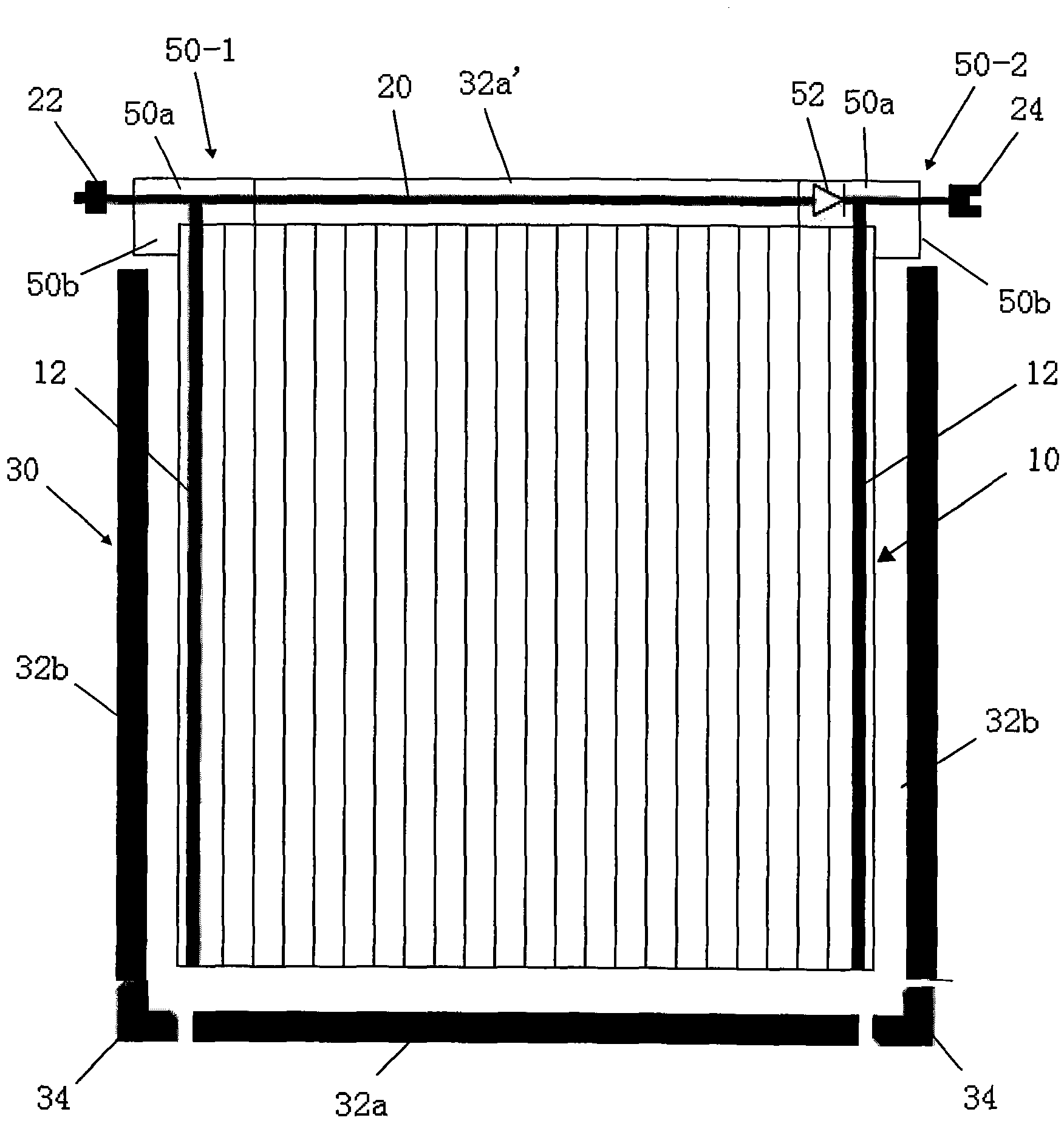

[0048] Such as figure 2 As shown, according to a preferred embodiment of the present application, a thin film solar cell module mainly includes a cell panel 10 , a frame 30 and a junction box 50 .

[0049] In the illustrated embodiment, the panel 10 is generally rectangular, thereby defining the longitudinal and transverse directions of the panel.

[0050] In actual use, the battery panel 10 has a front side facing sunlight and a back side facing away from sunlight.

[0051] As an example (not shown), the cell panel 10 of the thin-film solar cell module according to the present application mainly includes (from the back side to the front side direction): a cell substrate (such as made of glass, polymer, metal, etc.), attached to The battery sheet layer on the front side of the battery substrate (amorphous silicon type, microcrystalline silicon t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com