Light and fiber splitting box of optical divider slot

A technology of splitting fiber box and optical splitter, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of not adopting fiber digging technology and not having the function of storing passing optical fibers, etc., so as to achieve clear and convenient construction, and is conducive to popularization and Effects that are inexpensive to apply, manufacture and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

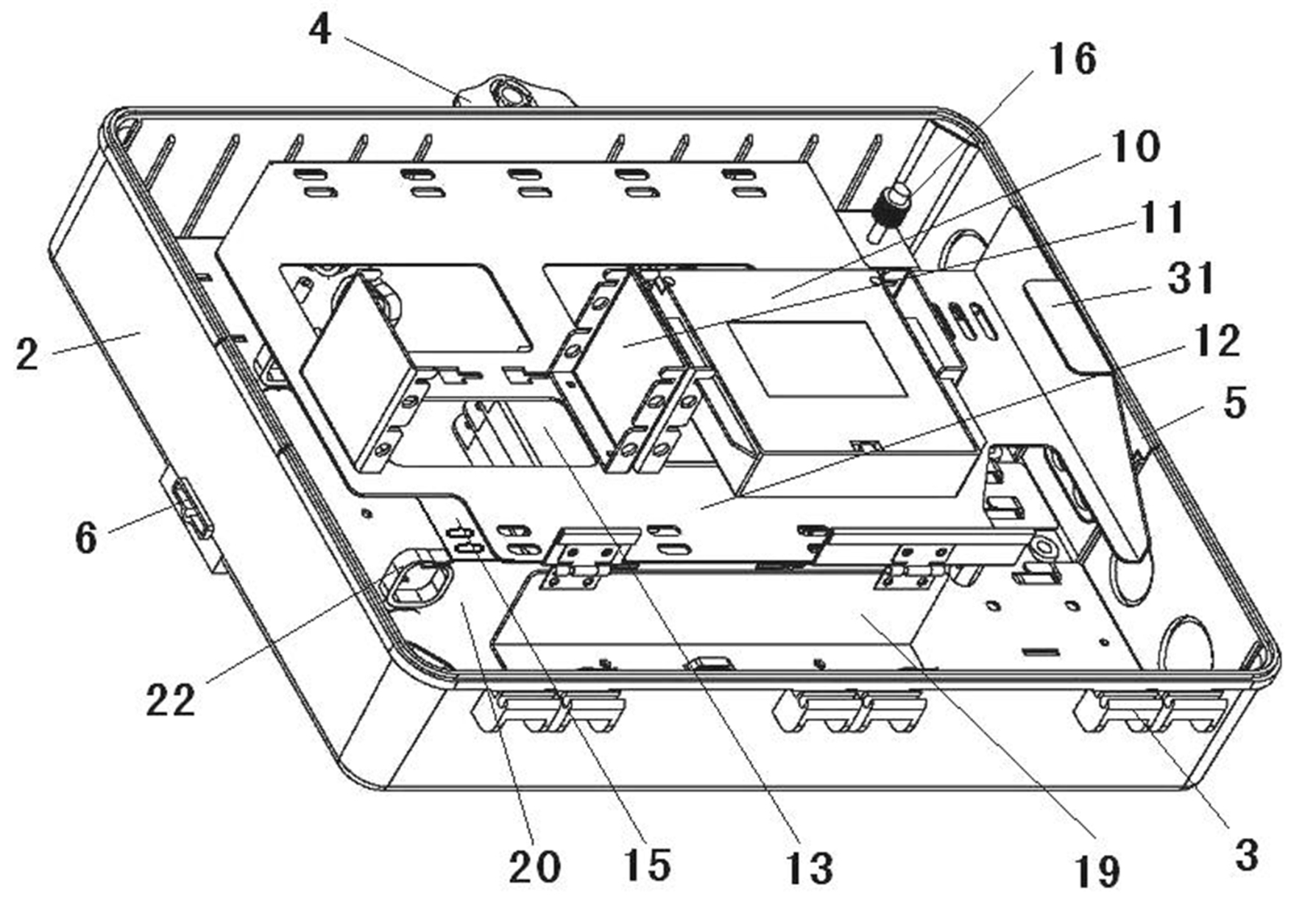

[0033] The specific implementations of the optical splitter slot splitting fiber box of the present invention are given below with reference to the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following implementations.

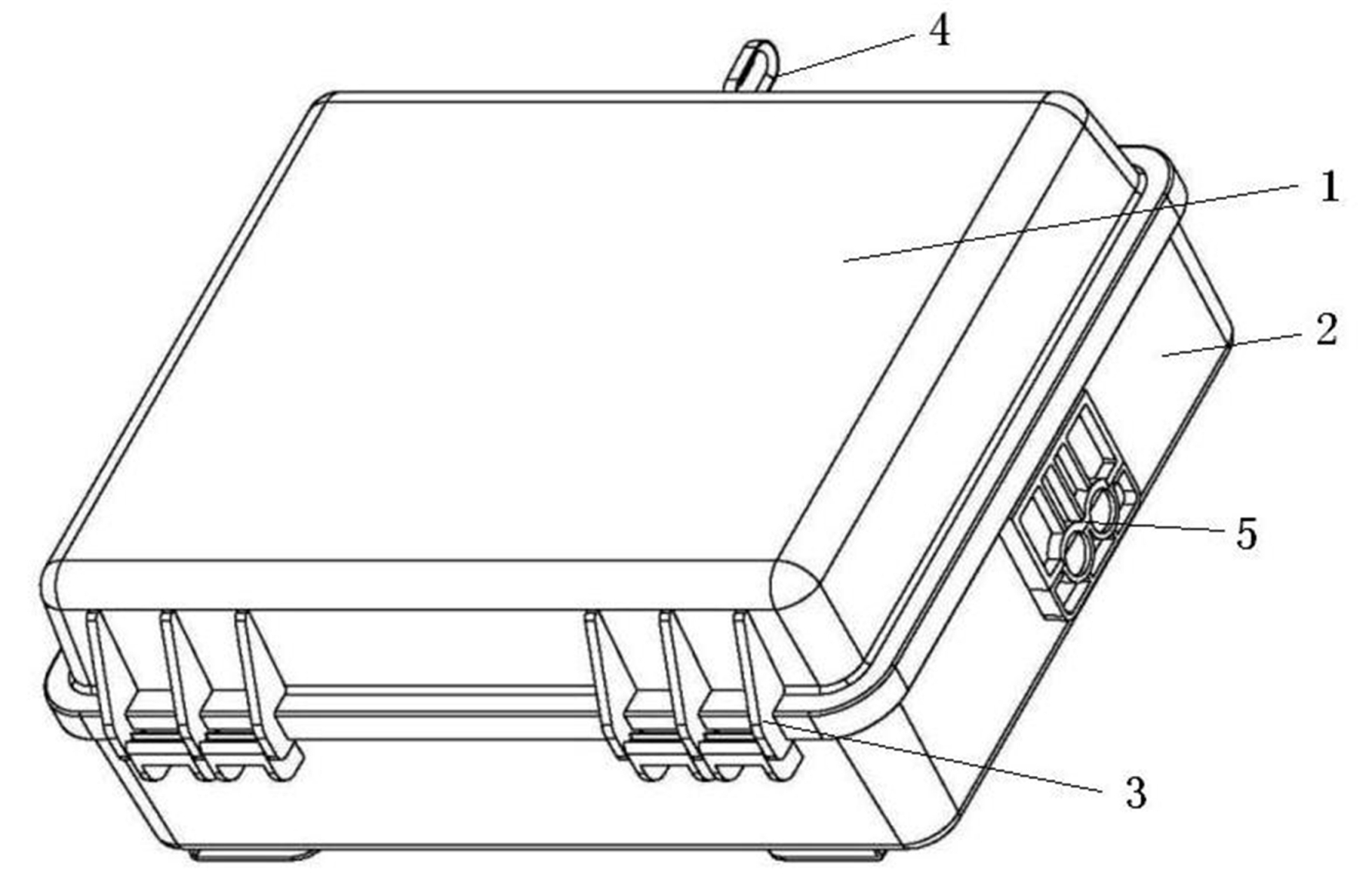

[0034] See attached figure 1 . An optical splitter slot splitting fiber box, comprising a box cover 1 and a box body 2. The box cover 1 and the box body 2 can be made of ABS+PC alloy polyester material, which is anti-aging and anti-ultraviolet. The size of the box body 2 can be manufactured according to the size of 420 mm high x 320 mm wide x 125 mm deep. It is 62kPa~101kPa.

[0035] Ribs are arranged on the inner layer of the box cover 1 and the box body 2 for reinforcement. A hinge 3 is installed on one side of the case cover 1 and the case body 2 , and a lock catch 4 is installed on the other side of the case cover 1 and the case body 2 . The lock buckle 4 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com