Internal gear pump

A technology of internal gear pumps and internal gears, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as obvious internal leakage, achieve long service life, increase pressure and overall delivery efficiency, and reduce internal leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

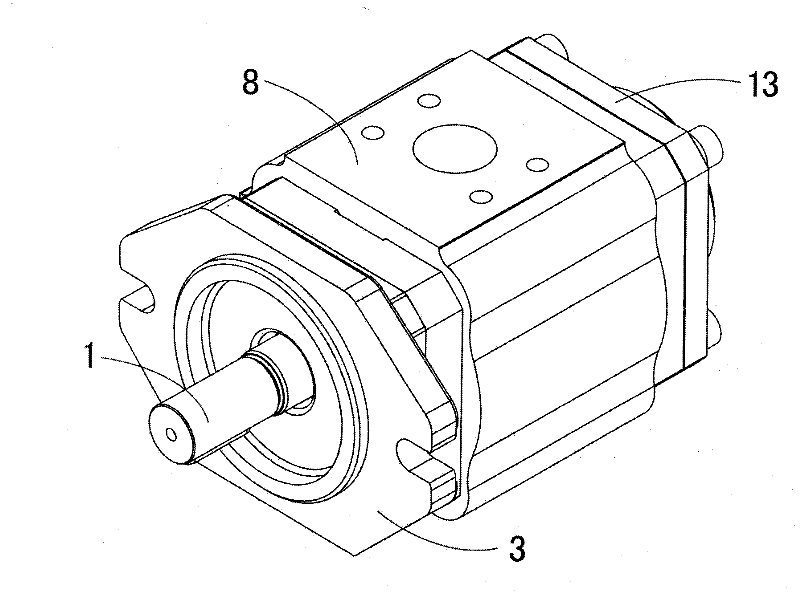

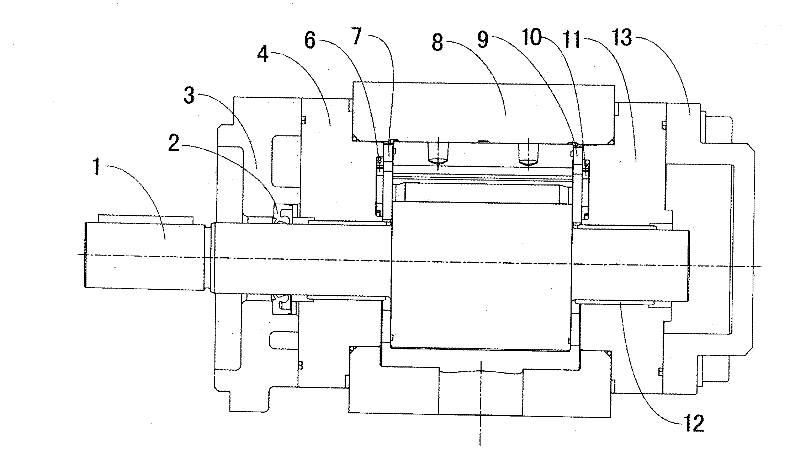

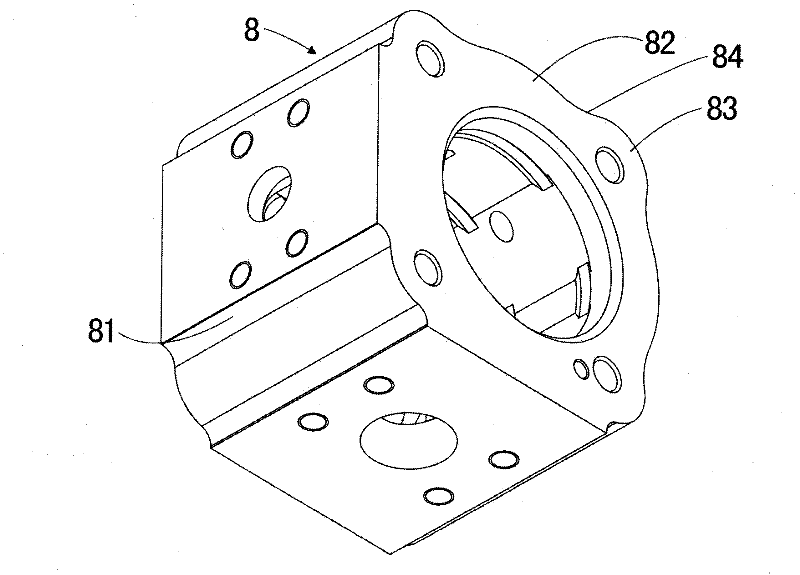

[0028] See Figure 1 to Figure 12 , the internal meshing gear pump includes a pump body 8, front and rear covers 4, 11 located at both ends thereof, and an eccentrically meshed internal gear 16 and an internal gear shaft 1 in the pump body 8, and the internal gear shaft 1 in the pump body 8 In the cavity formed by the meshing between the gear 16 and the inner gear shaft 1, there is a special-shaped piece 19 which divides it into two parts. Between the special-shaped piece 19 and the front and rear covers 4, 11, there are respectively front and rear distribution valves in sequence. Disks 7,9 and front and rear brackets 6,10 are provided with elastic seals 5 between the front and rear covers 4,11 and front and rear brackets 4,10, through the pre-compression of the elastic seals 5 Axial wear compensation is performed on the front and rear f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com