At present, the manual cleaning of the screen must be done by dust-free paper or rags, cleaning fluid, gloves and other tools. Therefore, many problems have arisen, such as the damage to the

human body caused by the cleaning fluid and ink gas, high production costs and A lot of waste of cleaning materials and the

impact of oily garbage brought by cleaning the net with dust-free paper or rags on the environment, etc.

Let me talk about the nature and use of cleaning tools and materials used in manual cleaning of screens: Dust-free paper is generally made of artificial fibers and

imitation fibers, and its insoluble in water is mainly for the components used to stain the screen with washing water. Generally, it is made of

toluene The chemical properties of hexanone are synthesized, and its

advantage is that this kind of dust-free paper is insoluble in water and insoluble in cleaning liquids containing

corrosive chemical components, so its fibers or debris will not be left on the cleaned screen or cause damage. The mesh is blocked, but the

disadvantage is that the cost is high and because it is incompatible with water and non-degradable, the garbage produced will bring great harm to the environment

Cleaning with rags: the

advantage is that it is easy to get and cheap, but it is only suitable for cleaning screens that do not require high printing quality, because cleaning screens with rags often leaves behind the cleaned screens and mesh holes. The printing quality will increase due to fine cloth scraps, so it is rarely used in the production with relatively high printing quality requirements.

[0004] Cleaning solution: At present, there are many kinds of cleaning solutions on the market to divide the market according to different purposes and different effects. The cleaning solutions used to clean the screen printing screen are mainly divided into two categories: water cleaning and cleaning solutions containing chemical properties. Water cleaning It is mainly used to

clean water-soluble inks that are more

environmentally friendly. The cleaning liquid containing chemical properties is mainly used to clean inks that contain oil and chemical components. The main components are generally synthesized by the chemical properties of

toluene and

cyclohexanone. Water-based inks are not as dominant as inks containing oil, chemical components or

low toxicity, which may be limited by various reasons such as price and technology. Therefore, inks containing oil, chemical components or

low toxicity are currently dominant, and this It also caused different degrees of harm to the environment, the staff who have been dealing with printing for a long time and the staff who cleaned the screen, especially the smell produced by the ink and the cleaning solution with chemical components is not only pungent but also low-toxic. If the cleaning solution containing chemical components directly touches the

sensitive skin and is not cleaned in time, there will be a

burning sensation. Therefore, gloves must be worn when cleaning the screen or touching the cleaning solution. Therefore, it can be seen that a large amount of irresistible damage caused by manual cleaning of the screen. Degraded dust-free paper, or hard-to-degrade rags and inks with

low toxicity are treated as

industrial waste, and the volatilization of cleaning fluids containing chemical substances has a huge

impact on the

human body and the environment

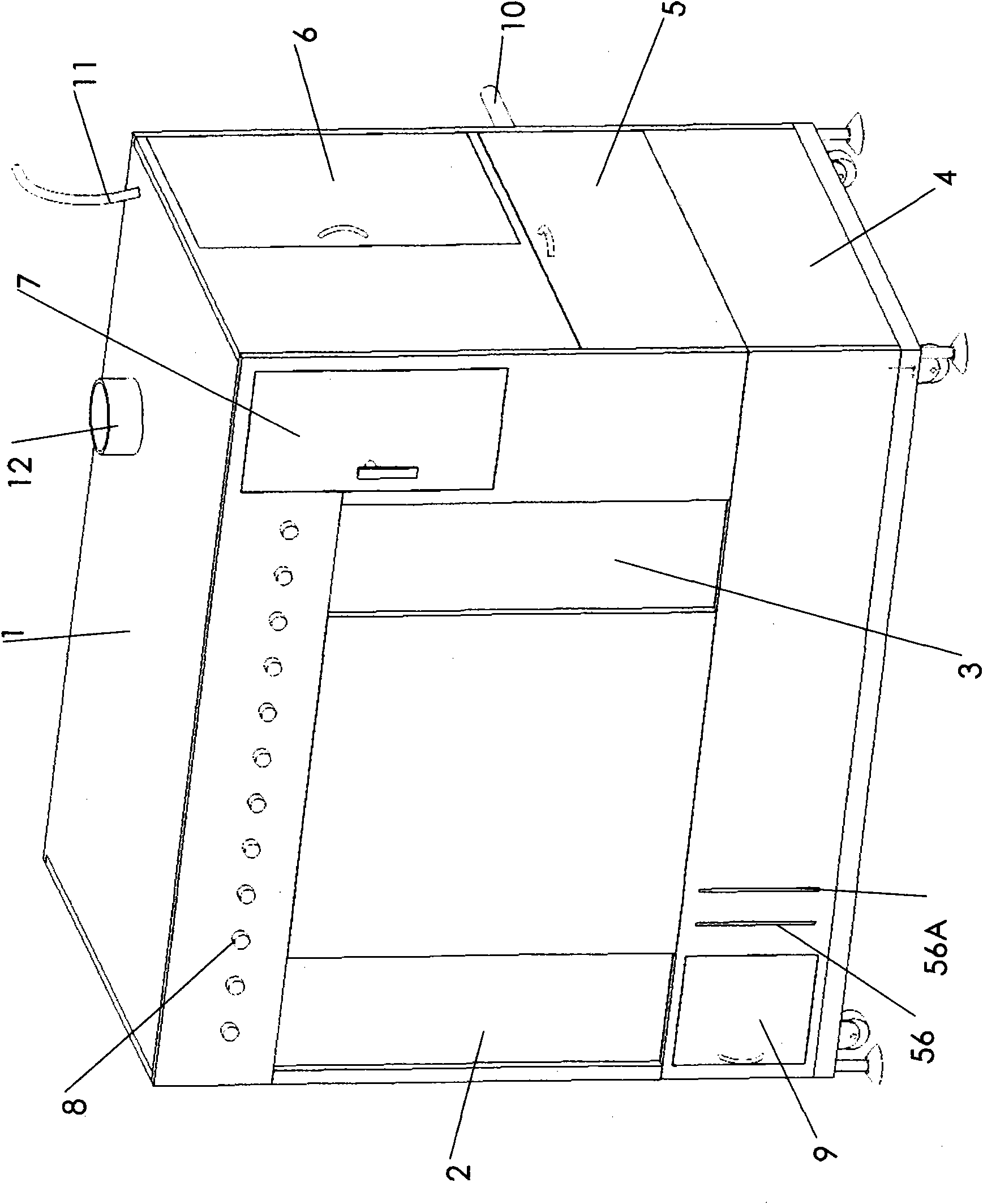

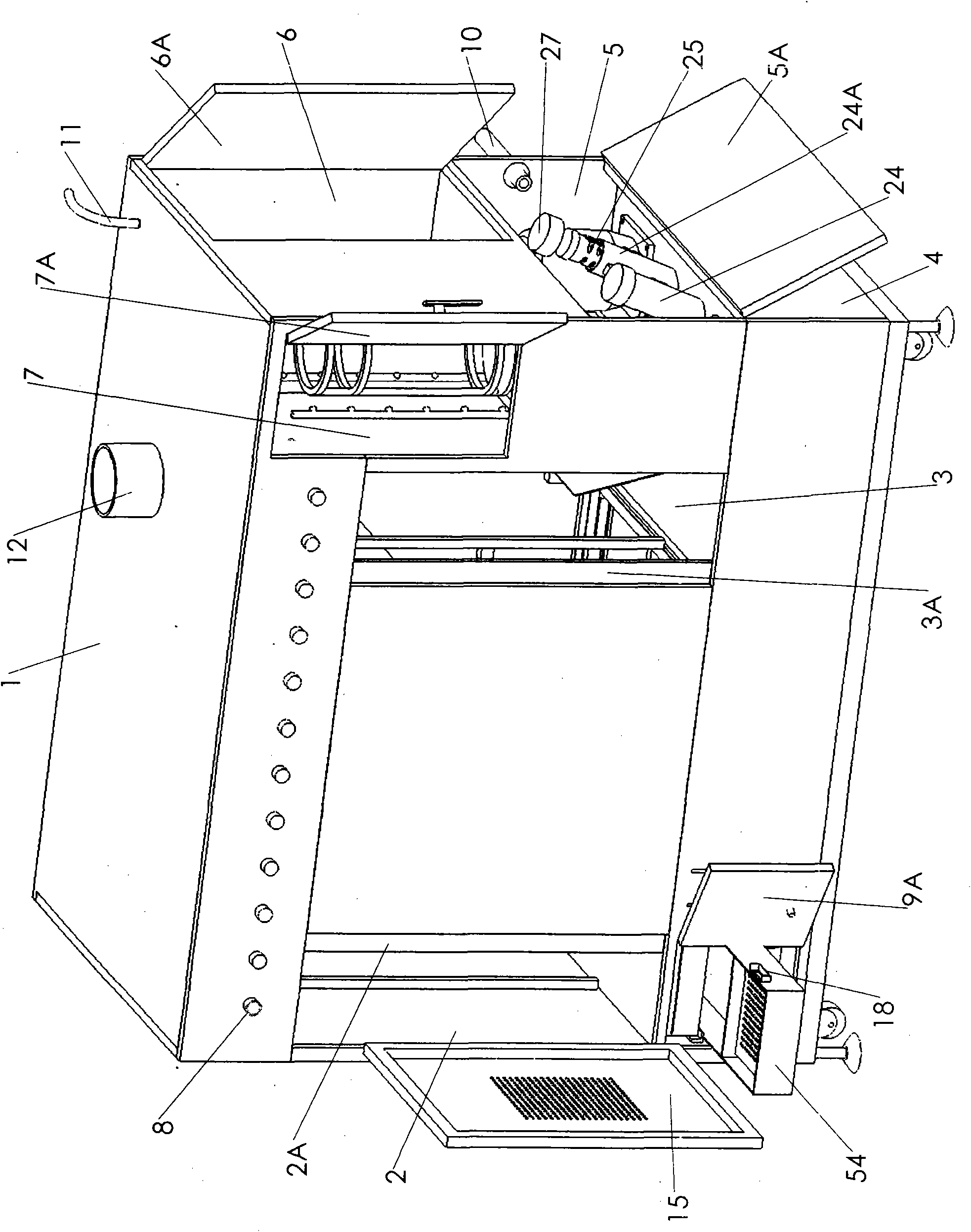

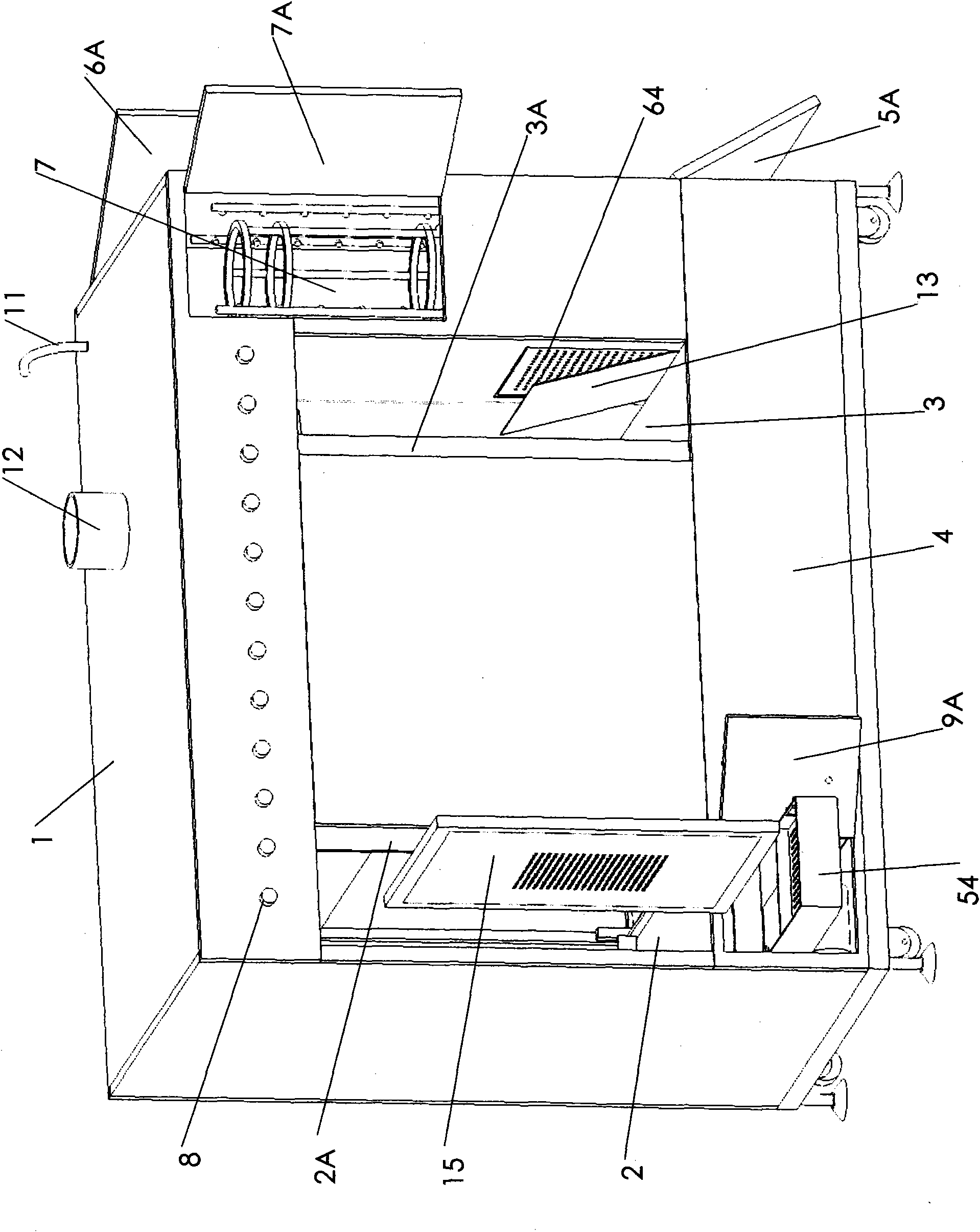

[0005]Equipment cleaning is to complete the automatic cleaning of the screen through

mechanical equipment. At present, most of the screen cleaning machines in the existing technology and on the market use a relatively sealed box It is equipped with cleaning liquid,

ultrasonic generator, cleaning

nozzle or

heat energy, and the screen is manually put into or conveyed by the transmission device to transfer the screen to the position with cleaning

nozzle or directly soaked in the cleaning liquid for cleaning. The advantages are: reduced labor costs, no need for dust-free paper or rag materials, and the screen cleaning becomes fast and clean. Because it is cleaned in a relatively sealed cavity or an additional exhaust

system is added, it contains

chemical cleaning. The pungent taste of the liquid and the problem of easy

evaporation can be solved very well, so that the harm to the

human body and the environment is relatively less than that caused by manual

hand washing; the

disadvantage is that the current cleaning machines mostly use the cleaning

nozzle to directly clean the oily

dirt Then simply filter the cleaning solution containing oil, so that the cleaning solution after circular cleaning will quickly become turbid, making the effect of cleaning the screen poor, resulting in frequent replacement of cleaning solution, and cleaning the oily network at the same time The cleaning solution of the plate is corrosive to the sealing glue used to stick the screen stretcher on the screen frame

At present, there is also a screen machine cleaning equipment in the market that is divided into two stages of cleaning. The first stage of washing liquid and the second stage of cleaning liquid are completely separated. After the first stage of flushing, use the pump to pump back the cleaning liquid for

filtration or to the recycling machine for

recovery. , the second-stage cleaning liquid is filtered and then pumped back to the first stage for rinsing. The second stage uses a clean cleaning liquid, which has the

advantage of being cleaner than the traditional one-stage cleaning method and can reduce the chance that tiny particles will block the screen. The disadvantage is that the amount of cleaning liquid to be recovered and filtered is large, and at the same time, the use of the screen is caused by the

corrosion of the

adhesive agent that fixes the screen frame and the mesh because the cleaning liquid is directly sprayed on the frame of the screen and the screen. Disadvantages such as shortened lifespan

Login to View More

Login to View More  Login to View More

Login to View More