Overburden pressure system for three-dimensional model

A three-dimensional model and overburden technology, which is applied in the fields of production fluids, wellbore/well components, and earthwork drilling, etc., can solve the problems of large dead volume, experimental data errors, jumping flow, etc., and achieve the effect of ensuring the experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

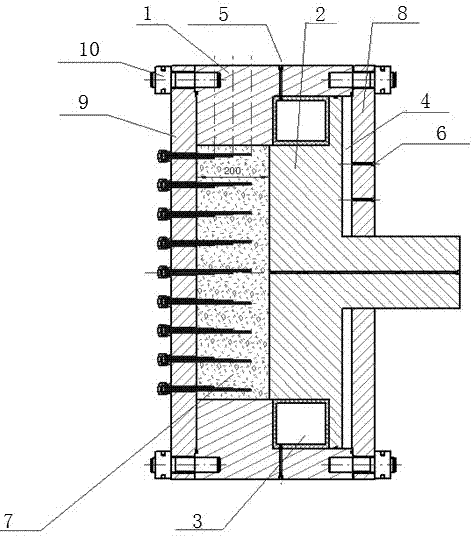

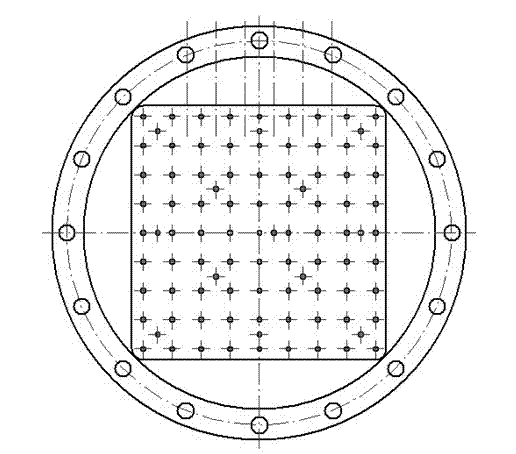

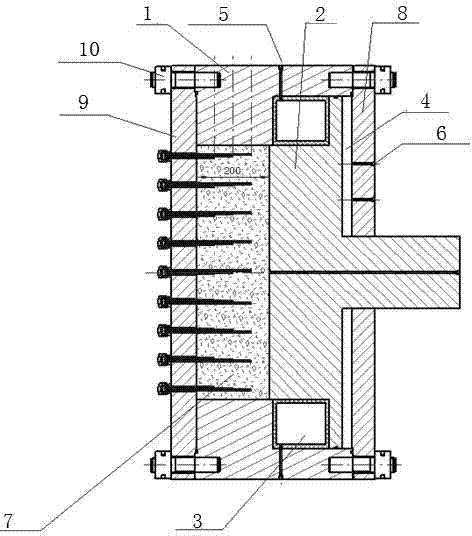

[0019] like figure 1 As shown, the three-dimensional model overburden system of the present invention includes a cylinder body 1, a piston 2 disposed in the cylinder body 1, a sand filling layer 7 connected to the piston 2, and an upper flange 8 and a lower flange for connection. 9 and fastening bolts 10, the piston is composed of a square piston and a circular piston, four half-moon-shaped capsule chambers 3 are arranged between the piston 1 and the cylinder body 2, and the capsule chamber 3 is located at the intersection of the square piston and the circular piston , One side of the cylinder body 1 is provided with a circular pressure chamber 4, the capsule chamber 3 is connected with a capsule chamber injection port 5, and the circular pressure chamber 4 is connected with a pressure chamber injection port 6.

[0020] During work, the hydraulic pump injects liquid to pressurize the overburden chamber 4, and the piston 2 compresses the sand filling layer 7, so that the sand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com