Device for simulating dissolved oxygen corrosion of whole wellbore pipe column of water injection well

A technology for simulating devices and water injection wells, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficult to simulate dissolved oxygen corrosion behavior, reduce experiment cost, ensure experiment accuracy, and reduce experiment time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

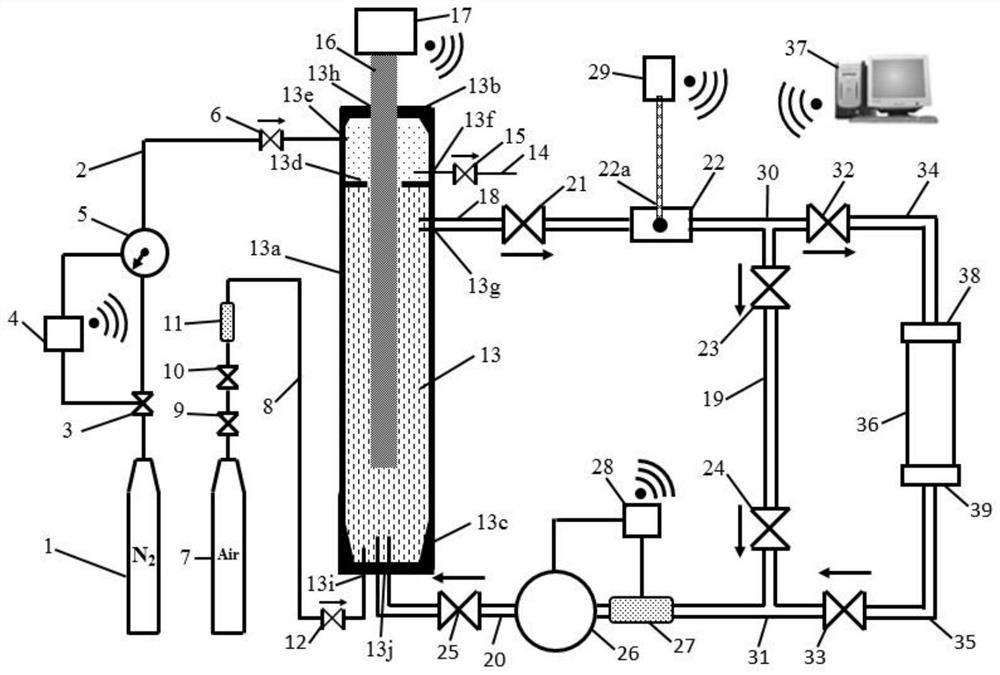

[0031] refer to figure 1 , an embodiment of a dissolved oxygen corrosion simulation device for a full wellbore string of a water injection well, comprising a liquid storage standpipe 13, an air injection system, a nitrogen pressurization system, an electric heating system, an aeration circulation system, a dissolved oxygen monitoring system, and a corrosion reaction Circulatory system, experimental auxiliary control system.

[0032] The liquid storage riser 13 includes a liquid storage riser body 13a, a liquid storage riser upper cover 13b and a liquid storage riser lower cover 13c, and the upper inner side of the liquid storage riser body 13a is provided with an annular partition 13d, The upper part of the left side is provided with a pressure hole 13e, and the upper part of the right side is provided with an exhaust hole 13f and a liquid outlet hole 13g. The air hole 13f and the liquid outlet hole 13g are located at the adjacent position below the annular partition 13d, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com