Wind/solar/electric complementary network anticorrosion system for buried steel pipelines

A complementary network and wind power technology, applied in the field of buried steel pipeline wind power complementary network anti-corrosion system, can solve the problems of inconvenient power consumption for pipeline protection, improve operational reliability, low cost, and reduce line patrol personnel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

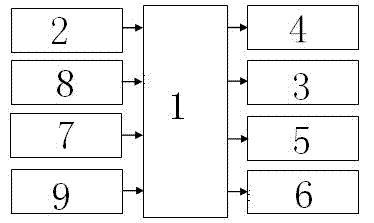

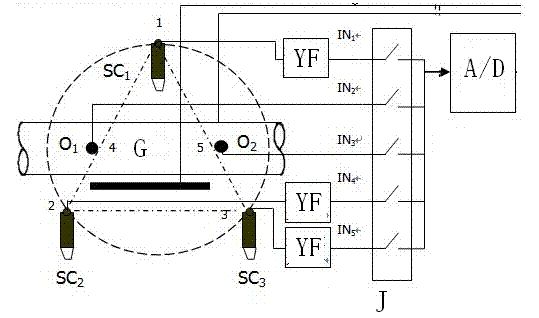

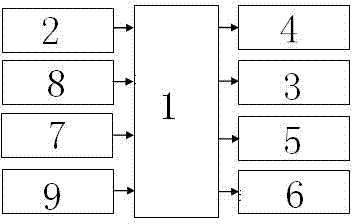

[0022] Embodiment of the present invention: the structure of the buried steel pipeline wind and electricity complementary network type anticorrosion system is as follows figure 1 As shown, it includes a single-chip microcomputer module 1, and the single-chip microcomputer module 1 is connected with a data acquisition module 2, a field monitoring module 3, a display module 4, an integrated anti-corrosion module 5, a wireless detection and SMS module 6, a wind-power complementary power supply module 9 and buttons Module 7; a clock module 8 is also connected to the single-chip microcomputer module 1; the field monitoring module 3 includes a camera and a microwave induction probe; the wind and electricity complementary power supply module 5 includes a wind generator, a solar battery, and a civilian electrical module .

[0023] The present invention usually works in the field. In order to improve safety, a lightning protection device is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com