Hemp stalk composite cellulose ether and preparation method thereof

A hemp stalk and cellulose technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of ecological damage, difficult to decompose, etc., and achieve the effects of less sewage discharge, easy desizing, and rich raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 hemp stalk cellulose compound ether

[0040] 1. Grind the cleaned and dried hemp stalk to 200 mesh hemp stalk powder.

[0041] 2. Soak 175g of hemp stalk powder in 1000g of 8g / 100ml sodium hydroxide solution and stir for alkalization to generate alkali cellulose, and react at 20°C for 50 minutes.

[0042] 3. Add 280g of methyl chloride to the alkali cellulose. When the reactor temperature was raised to 42°C, 280g of ethylene oxide was added, and the temperature was gradually raised to 48°C within 2.5 hours. Then, it was kept at 55°C for 1.5 hours to complete the etherification. After the reaction was finished, the reactor was cooled to 20°C and exhausted. The crude product was mixed with 65g of 50wt% citric acid to adjust the pH to 5.0, and then 13g of 40wt% liquid glyoxal was added. After thorough mixing, heat to 70° C. for 20 minutes to obtain surface-crosslinked nonionic hemp stalk cellulose complex ether. Cool the crude product t...

Embodiment 2

[0047] The preparation of embodiment 2 hemp stalk cellulose compound ethers

[0048] 1. Grind the washed and dried hemp stalk to 400 mesh hemp stalk powder.

[0049] 2. Soak 175g of hemp stalk powder in 1000g of 8g / 100ml sodium hydroxide solution and stir for alkalization to generate alkali cellulose, and react at 20°C for 50 minutes.

[0050] 3. Add 280g of methyl chloride to the alkali cellulose. When the reactor was heated to 42°C, 280g of propylene oxide was added, and the temperature was gradually raised to 48°C within 2.5 hours. Then, it was kept at 55°C for 1.5 hours to complete the etherification. After the reaction, the reactor was cooled to 25° C. and exhausted. The crude product was mixed with 65g of 50wt% citric acid to adjust the pH to 5.0, and then 13g of 40wt% glyoxal was added. After being fully mixed, heat to 70°C for 20 minutes, cool the crude product to 25°C, wash twice with water, filter, and dry at 80°C to obtain a surface-crosslinked non-ionic hemp st...

Embodiment 3

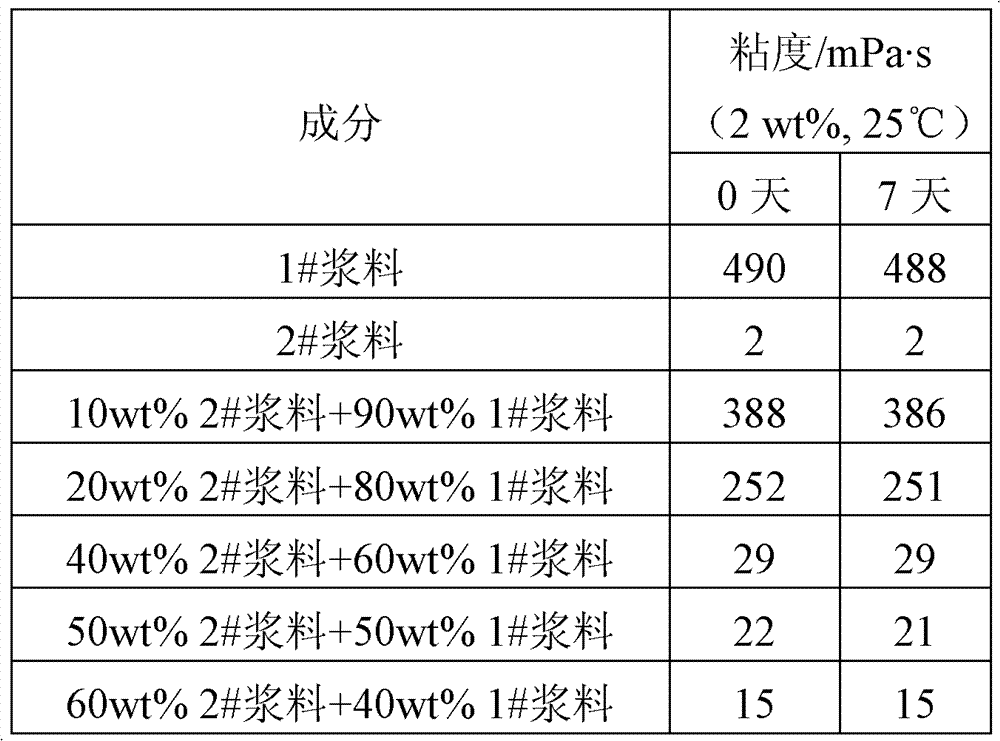

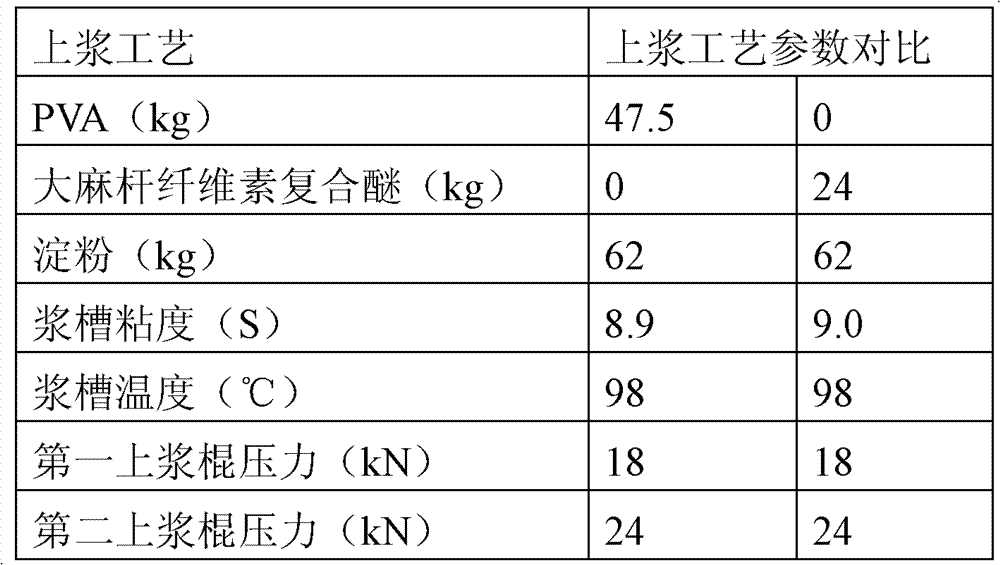

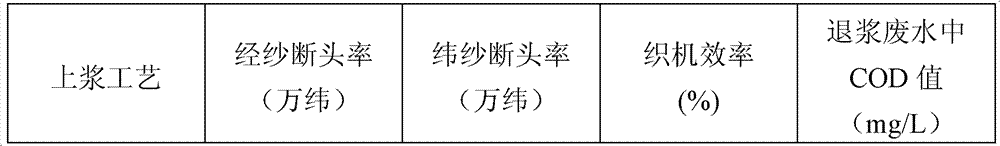

[0056] Embodiment 3 sizing effect evaluation

[0057] Taking 40s×40s, 110×76 plain cotton cloth as an example, the yarn sizing process is as described in "Weaving Science" (Edited by Zhu Sukang, China Textile Press, Beijing, 121-122). In the sizing process parameters, use GA310 sizing machine, adopt 1 part of compounded hemp stalk cellulose compound ether to replace 2 parts of PVA sizing, the composition of the hemp stalk cellulose compound ether is 40wt% of 2# size and 60wt% % of 1# slurry. The comparison data of sizing process parameters are shown in Table 3, and the comparison results of sizing process effects are shown in Table 4:

[0058] Table 3 Comparison of sizing process parameters

[0059]

[0060] Table 4 Comparison of sizing process effects

[0061]

[0062]

[0063] After hemp stalk cellulose composite ether sizing, during the weaving process, the warp yarn breakage rate is 9.7 / 100,000 wefts, the weft yarn breakage rate is 9.5 / 100,000 wefts, and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com