Preparation and application methods of modified polyepoxysuccinic acid scale and corrosion inhibitor

A technology of polyepoxysuccinic acid, scale and corrosion inhibitor, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., to achieve good biodegradability and water solubility, non-toxicity Destroy the ecological environment and increase the effect of scale and corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. Cyclization reaction and purification of cyclization products

[0026] aAdd 16g of NaOH and 36ml of water solvent solution into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 19.6g of maleic anhydride, and raise the temperature of the water bath to 55°C. After the water bath was heated to 55°C, the catalyst 1.2gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 70°C. After the temperature stabilizes, use a separatory funnel to evenly add 24ml of hydrogen peroxide dropwise within 35 minutes. At this point, 1:1 hydrochloric acid solution was used to adjust the pH to 6-7, and the mixed crude product was obtained after 1.5 hours of reaction.

[0027] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporatio...

Embodiment 2

[0033] A. Cyclization reaction and purification of cyclization products

[0034] aAdd 13g of NaOH and 35ml of water solvent solution into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 18g of maleic anhydride, and simultaneously raise the temperature of the water bath to 52°C. After the temperature of the water bath was raised to 52°C, the catalyst 1gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 65°C. After the temperature is stable, use a separatory funnel to evenly add 20ml of hydrogen peroxide dropwise within 30 minutes. At this time, start to adjust the pH=6-7 with 1:1 hydrochloric acid solution, and get mixed crude product after reacting for 1 hour.

[0035] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid afte...

Embodiment 3

[0041] A. Cyclization reaction and purification of cyclization products

[0042] a Add 18g of NaOH and 38ml of water solvent solution to the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 20g of maleic anhydride, and simultaneously raise the temperature of the water bath to 58°C. After the temperature of the water bath was raised to 58°C, the catalyst 1.5gNa was added 2 WO 4 Finally, raise the temperature of the water bath to 75°C, and after the temperature stabilizes, use a separatory funnel to evenly add 26ml of hydrogen peroxide dropwise within 40 minutes. At this point, a 1:1 hydrochloric acid solution was used to adjust the pH to 7, and the mixed crude product was obtained after 2 hours of reaction.

[0043] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

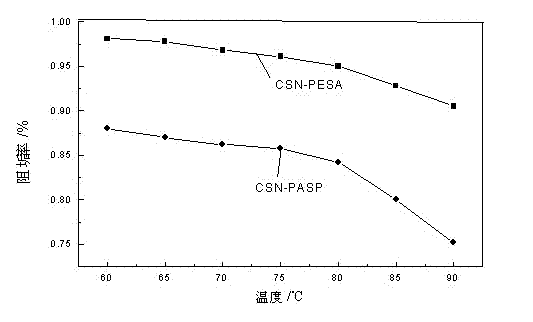

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com