Manufacturing method of biaxial stretching thick node plastic geogrid

A technology of geogrid and manufacturing method, which is applied in the field of manufacturing biaxially stretched thick-node plastic geogrid, can solve problems such as breakage, failure to guarantee normality, continuous production, and easy deformation of punches, etc., so as to avoid constraints, Improve the node thickness and tensile strength, the effect of small punch size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

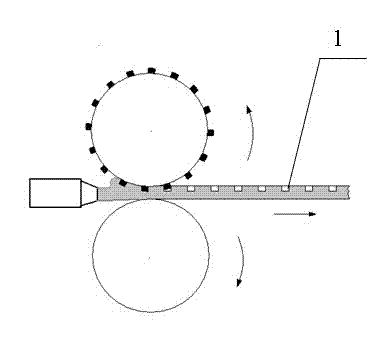

[0028] Example 1 as attached figure 1 Shown: A manufacturing method of biaxially stretched thick-node plastic geogrid, including a multi-roll press machine and a plastic extruder, the steps are as follows:

[0029] [1] Use a three-roll press and a plastic extruder to press the initial strip of a thick-node plastic geogrid with a set width and length with pits 1: the pits 1 are manufactured according to the prior art for two-way and three-way Or the number of rows and intervals of punched holes on the initial strip of four-way tensile plastic geogrid; wherein, the impermeable pits 1 set on both sides are on both sides of the smooth plastic flat strip one by one correspond to each other. The lower roll of the three-roll press machine used is a smooth roll, and the surface of the upper roll and the middle roll is provided with a flange that matches the size and shape of the pit 1 of the required initial strip. The gap feeding on the surface of the roller is used to suppress ...

Embodiment 2

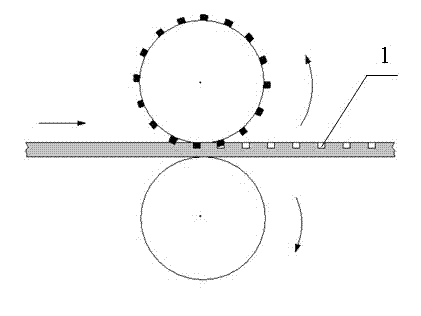

[0034] Example 2 as attached figure 2 Shown: step [1] described in embodiment 1 can also adopt twin-roll pressing machine and plastic extruder to press the initial strip of single-sided band pit 1, and lower roll is smooth roll, and the surface of upper roll is provided with required Flanges that match the size and shape of the pit 1 of the initial strip: or the upper and lower rolls of the two-roll press are provided with flanges that match the size and shape of the pit 1 of the desired initial strip , the plastic extruder feeds material in the gap between the surface of the upper roller and the lower roller, and presses out the initial strip with dimples 1 on both sides.

[0035] Steps [2] and [3] are the same as in Example 1.

Embodiment 3

[0036] Example 3 as attached image 3 Shown: A method of manufacturing biaxially stretched thick-node plastic geogrids, including smooth plastic flat strips, as follows:

[0037] [1] Use a double-roller hot press and a smooth plastic sheet to press the initial material belt of a thick-node plastic geogrid with a set width and length with pits 1: the upper and lower rollers of the double-roller hot press are equipped with A flange that matches the size and shape of the pit 1 of the required initial material tape, input a smooth plastic flat belt of corresponding thickness from the gap between the surface of the upper roller and the lower roller, and press out the initial material with pits 1 on both sides Belt: or the surface of the upper roll of the double-roll press machine is provided with a flange, and the lower roll is a smooth roll, then the initial material belt with pits 1 on one side is pressed.

[0038] Steps [2] and [3] are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com