High-precision controllable microscanning device based on piezoelectric ceramics and sliding guide rail

A piezoelectric ceramic and sliding guide technology, applied in the field of high-precision controllable micro-scanning devices, can solve the problems of low movement accuracy and poor direction consistency, and achieve the effects of high displacement repeatability, ensuring consistency and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

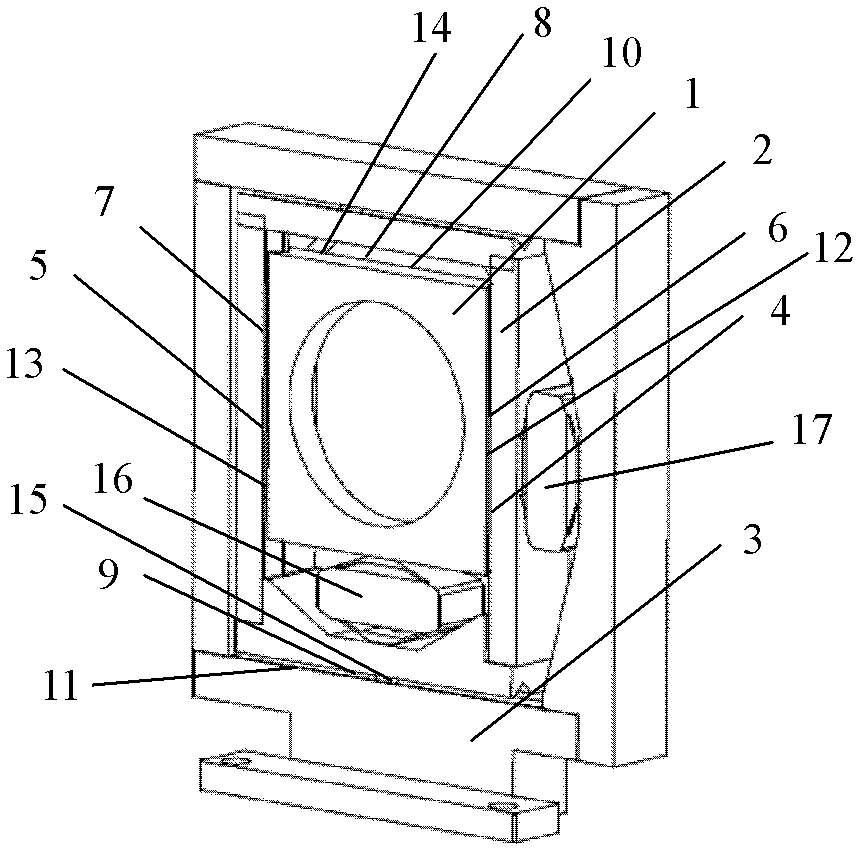

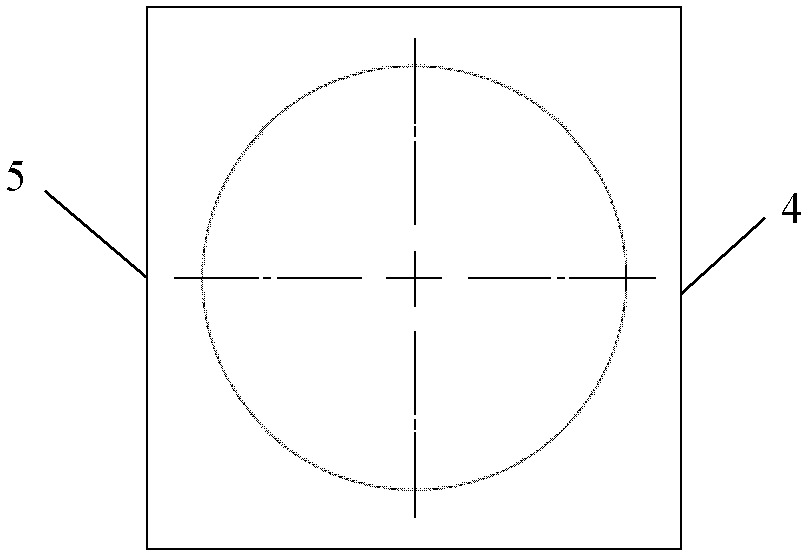

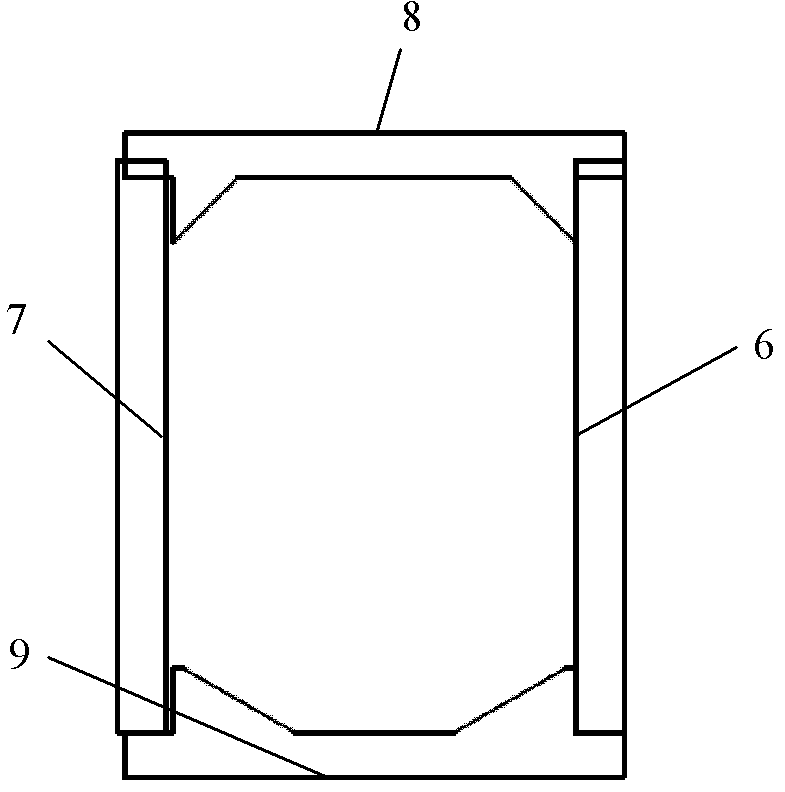

[0035] A high-precision controllable micro-scanning device based on piezoelectric ceramics and sliding rails, such as figure 1As shown, the vertical moving frame 1, the horizontal moving frame 2, the micro scanning mechanism frame 3, the first vertical dovetail slot 4, the second vertical dovetail slot 5, the third vertical dovetail slot 6, the fourth vertical dovetail slot 7, the first horizontal Dovetail groove 8, second horizontal dovetail groove 9, third horizontal dovetail groove 10, fourth horizontal dovetail groove 11, first ball 12, second ball 13, third ball 14, fourth ball 15, first piezoelectric ceramic 16. The second piezoelectric ceramic 17;

[0036] Wherein, the first piezoelectric ceramic 16 is used to drive the vertically movable frame 1, and the second piezoelectric ceramic 17 is used to drive the horizontally movable frame 2; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com