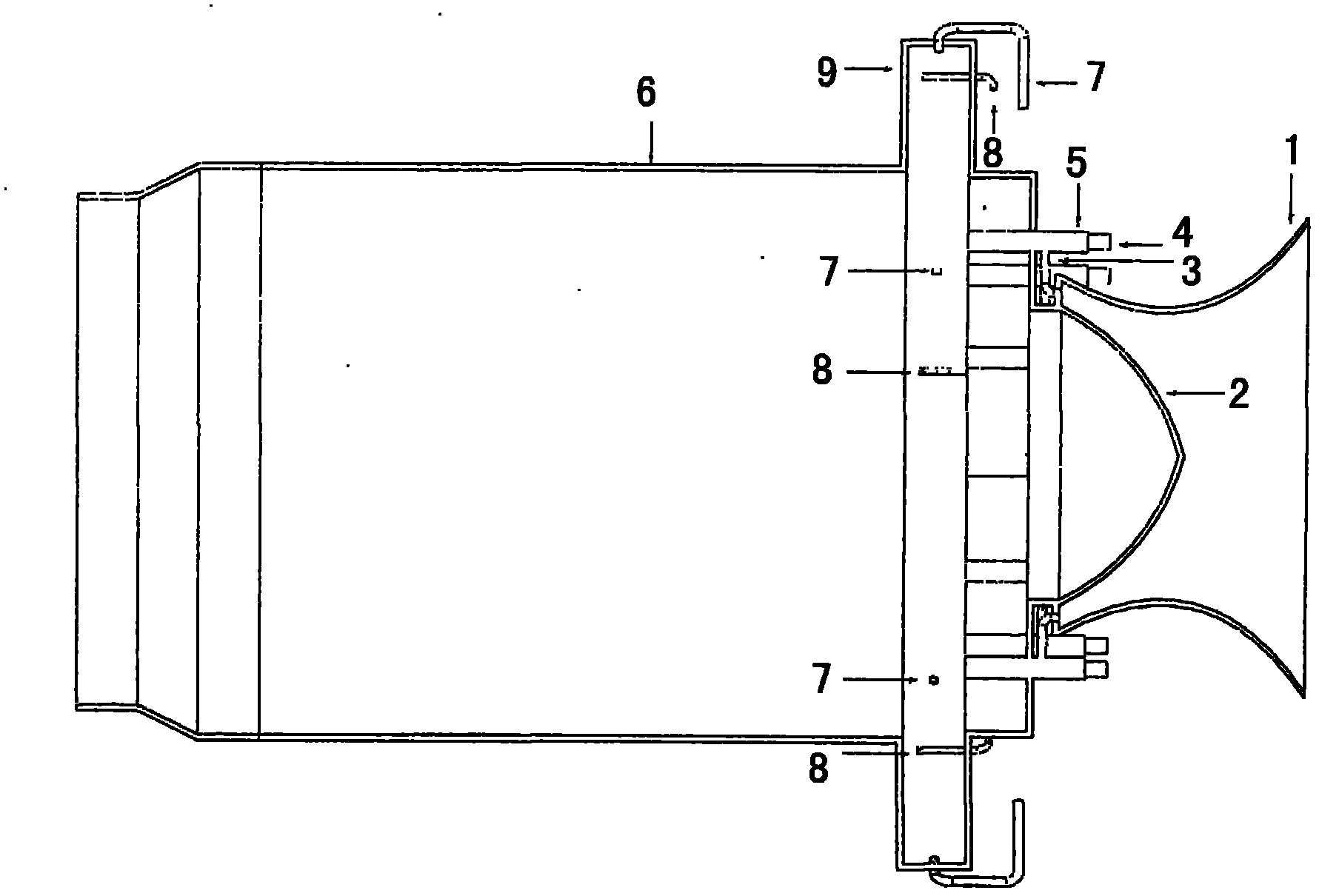

Flameless trapped vortex burner for gas turbine

A burner and vortex technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of low combustion noise, noise and pressure fluctuations, and achieve low combustion noise, small pressure fluctuations, and complete fuel combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

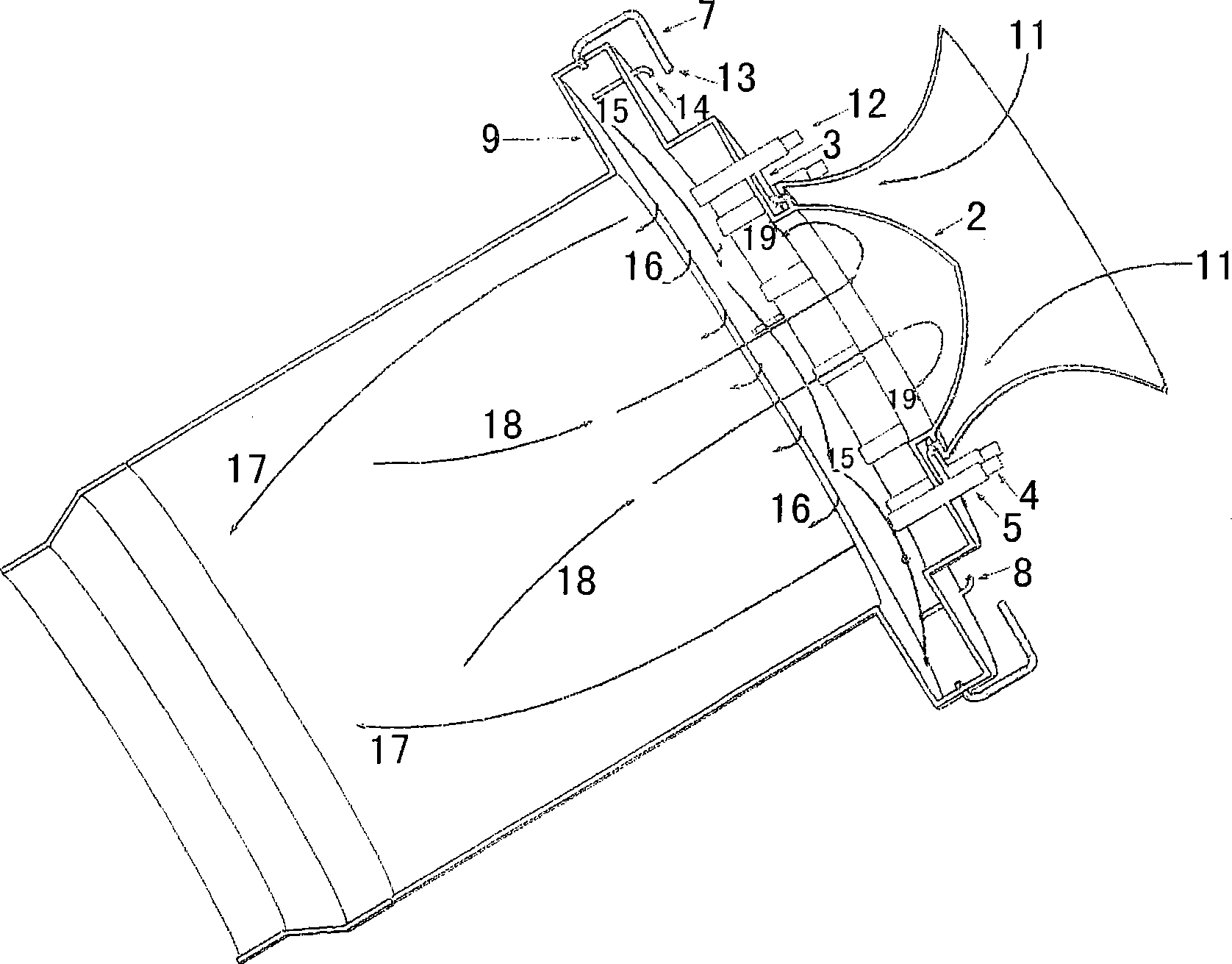

[0037] In a flameless vortex burner of a gas turbine according to the present invention, the existence of the duty flame in the concave cavity can greatly reduce the lean oil flameout equivalent ratio of the flameless combustion, even if the amount of oil is small, the high-temperature flue gas produced by the duty flame, It can also ensure the high temperature and low oxygen atmosphere of the oxidant, and maintain flameless combustion.

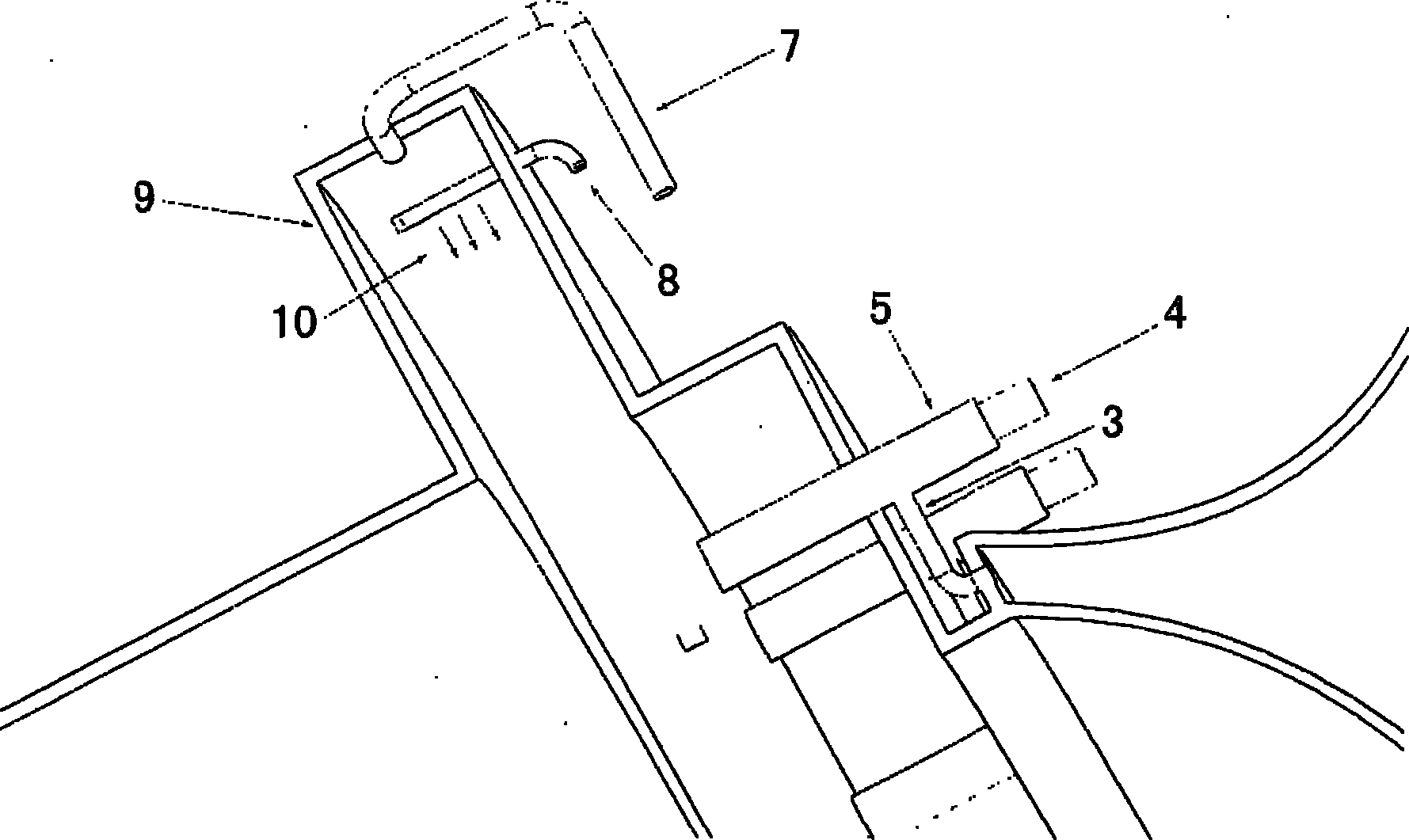

[0038] In the present invention, the cavity of the flame stabilizer with a trapped vortex cavity is in an annular structure, and its cross section is perpendicular to the axial direction, and is located downstream of the main flow gas inlet of the combustion chamber. 6 low-velocity air injection pipes and 6 low-velocity fuel nozzles are arranged around the concave cavity. The air injection direction is at an angle of 15 degrees to the horizontal direction. The duty flame in the hour cavity is not affected. The fuel in the vortex combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com