Blower

A blower and blower technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of difficult adjustment of air volume, complicated processing and installation, and large starting current, so as to solve the surge phenomenon, installation and processing Convenience, eliminates the effect of air separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

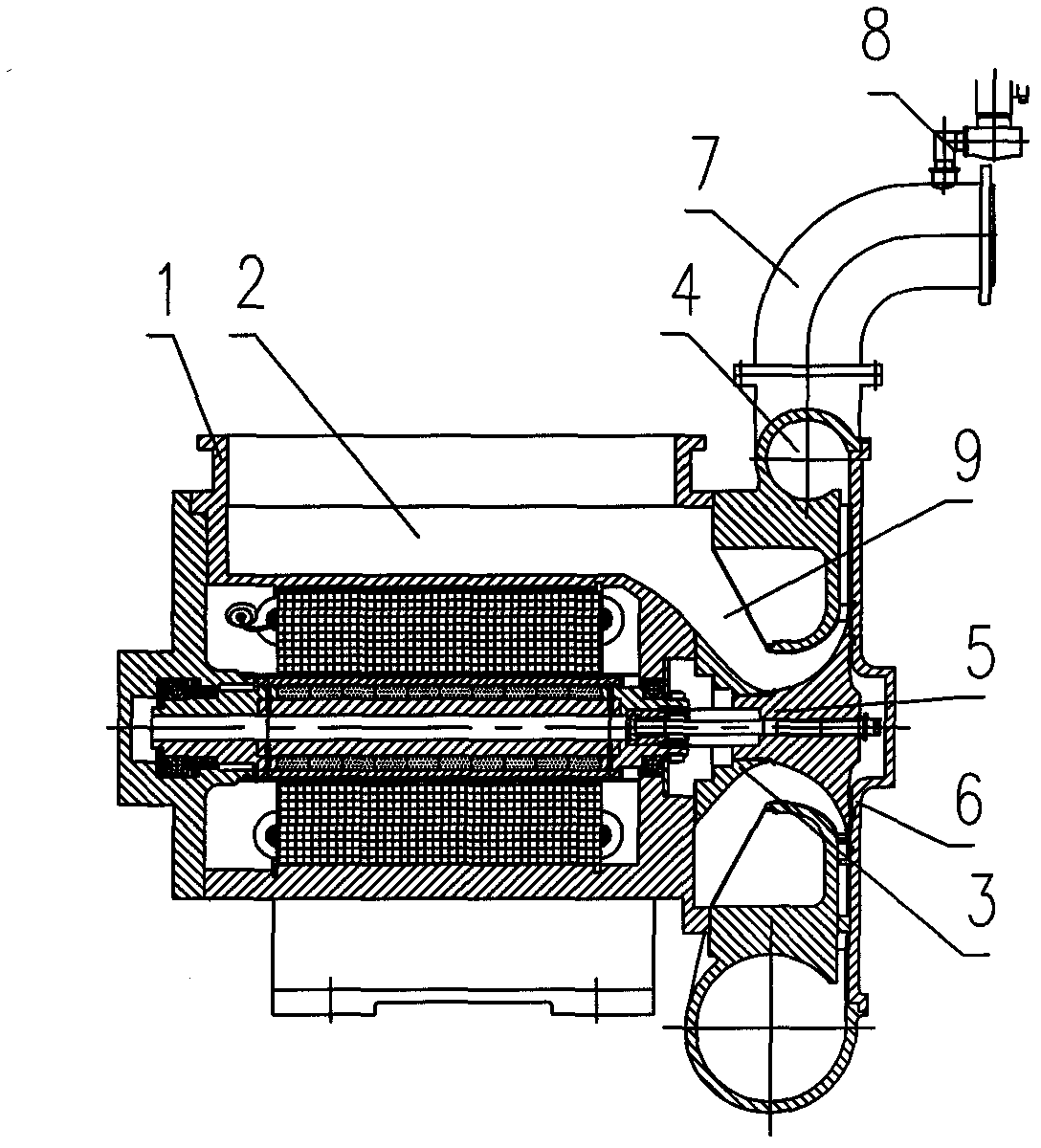

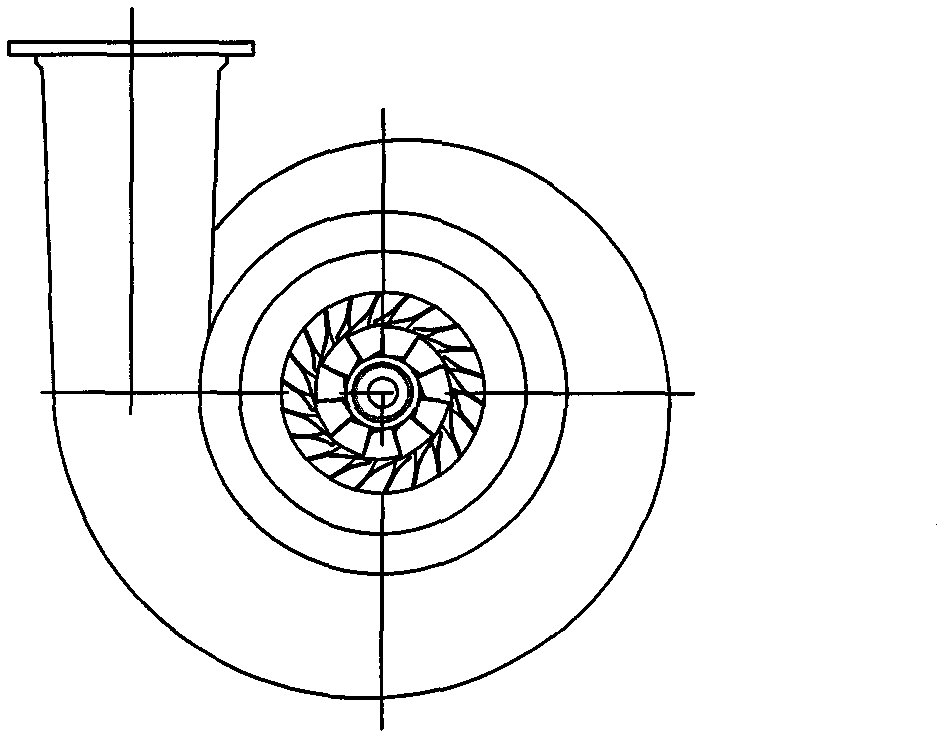

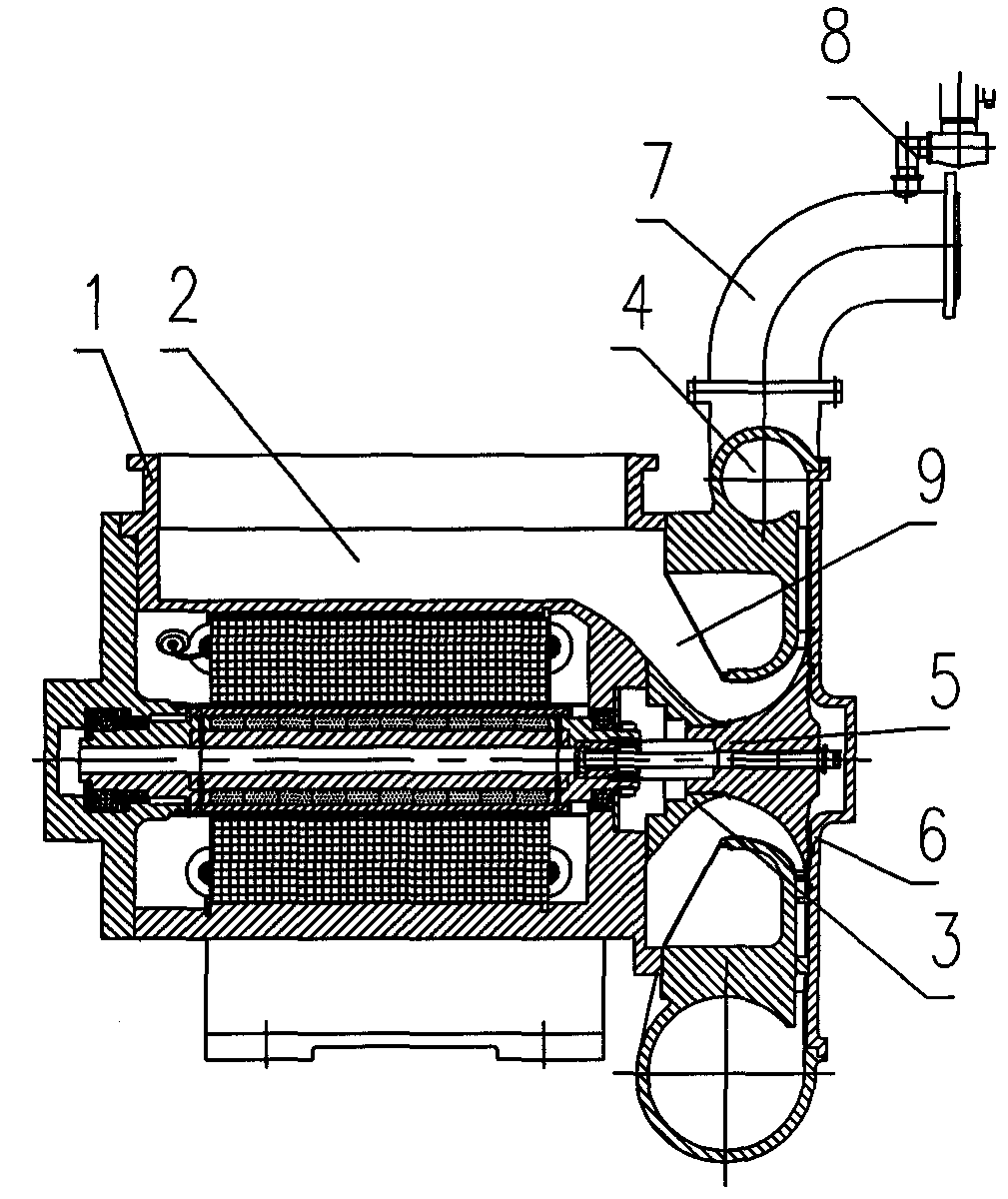

[0008] As shown in the figure, the blower includes a high-speed permanent magnet motor and a fan. The rotor of the high-speed permanent magnet motor is fixedly connected with the fan impeller 5 and can rotate synchronously; The large blades and small blades, the number of large blades and small blades are 11 respectively, the fan housing 6 is connected with the high-speed permanent magnet motor housing 1, and the fan housing 6 is provided with an annular guide cone 3, so The guide cone 3 described above is fixed on the motor housing 1 and forms an annular air chamber 9 with the fan housing 6. The motor housing 1 is provided with an air inlet 2 and communicates with the annular air chamber 9. The fan housing The body 6 is in the shape of a volute, and a swirl-shaped air passage 4 is arranged inside, and one side communicates with the annular air cavity 9, and the other side communicates with the air outlet elbow 7, and the air outlet elbow 7 is also provided with an air release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com