Novel diesel oil pour point depressant

A diesel pour point depressant and a new technology, applied in the field of oil additives, can solve the problems of high cost and limited effect of reducing the cooling filter point of high-wax diesel oil, and achieve the effect of reducing the cold filter point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

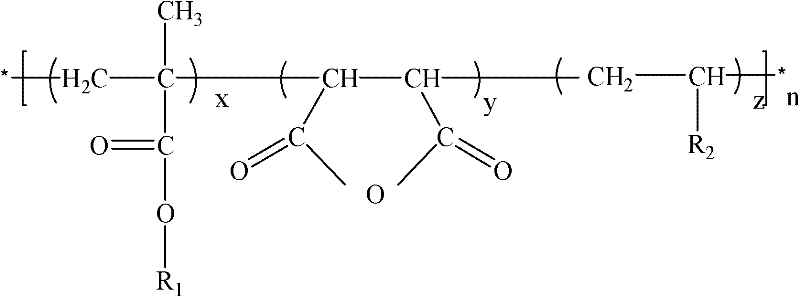

Method used

Image

Examples

Embodiment 1

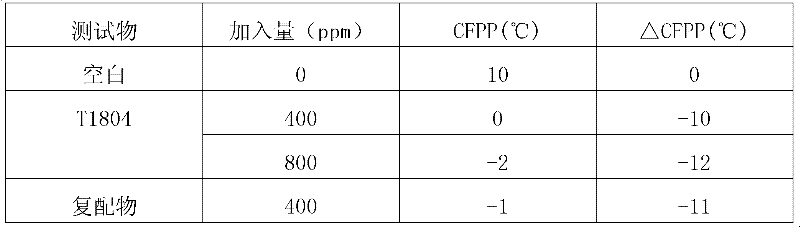

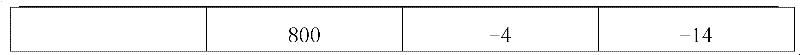

[0022] Example 1: Preparation of a multi-component compound of polyethylene vinyl acetate (T1804), SMA-MA-α copolymer and toluene

[0023] Into a three-necked flask equipped with a thermometer and a constant-speed stirring device was added 60g of polyethylene vinyl acetate (T1804), 15g of toluene was heated to 50℃ in a water bath, and 25g of hexadecyl methacrylate-maleic anhydride-α olefin ( SMA-MA-α) copolymer, stir at medium speed for 30 minutes, and finish when the compound in the flask is a homogeneous liquid.

Embodiment 2

[0024] Example 2: Preparation of the main component SMA-MA-α copolymer in the compound

[0025] Add 28g of hexadecyl methacrylate (SMA), 3g of maleic anhydride (MA), 6g of α-olefin to a four-necked flask equipped with a thermometer, condenser, dropping funnel and constant speed stirring device, and then add 20ml of toluene. Under nitrogen protection, the temperature was raised to 60°C under stirring to dissolve the reactants, and then 0.4 g of the catalyst benzoyl peroxide was weighed, and after it was fully dissolved in 20 ml of toluene, it was added to the dropping funnel for later use. When the temperature rises to 80-100°C, the catalyst is slowly added dropwise, and the reaction is continued for 5 hours under stirring to obtain hexadecyl methacrylate-maleic anhydride-α olefin (SMA-MA-α) copolymer

Embodiment 3

[0026] Example 3: Preparation of SMA-MA-α copolymer, the main component of the compound

[0027] Add 28g of hexadecyl methacrylate (SMA), 3g of maleic anhydride (MA), 6g of α-olefin to a four-necked flask equipped with a thermometer, condenser, dropping funnel and constant speed stirring device, and then add 20ml of toluene. Under nitrogen protection, the temperature was raised to 60°C under stirring to dissolve the reactants, then 0.8 g of the catalyst benzoyl peroxide was weighed, and after being fully dissolved in 20 ml of toluene, it was added to the dropping funnel for later use. When the temperature rises to 80-100°C, the catalyst is slowly added dropwise, and the reaction is continued for 5 hours under stirring to obtain hexadecyl methacrylate-maleic anhydride-α olefin (SMA-MA-α) copolymer

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com