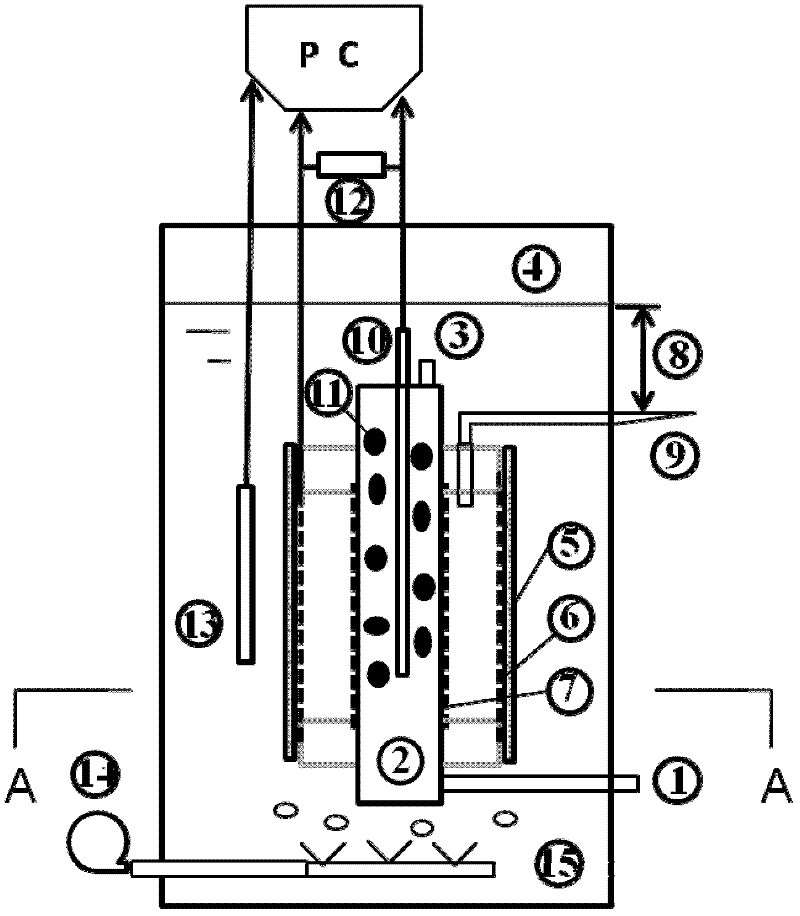

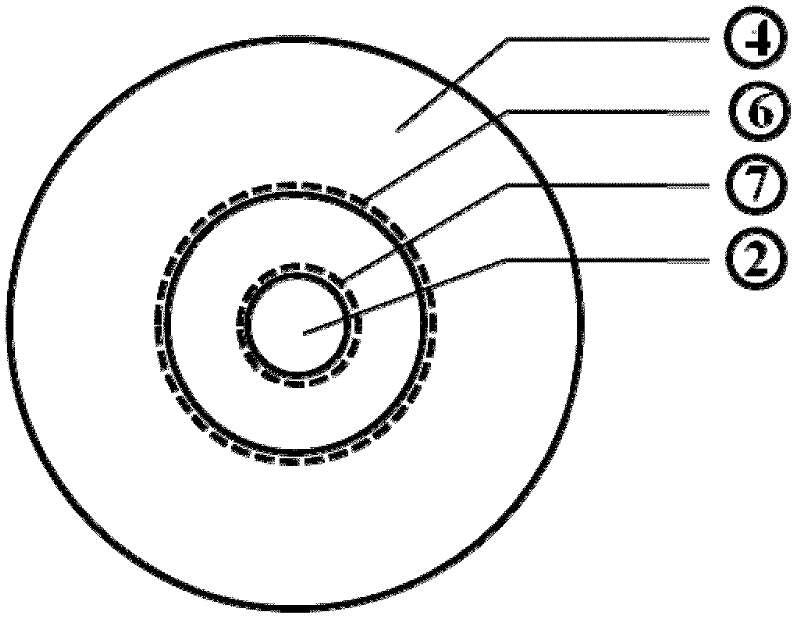

Bioelectrochemical film reactor device

A bioelectrochemical and membrane reactor technology, applied in the field of membrane bioreactors, can solve problems such as low biomass and poor effluent quality, and achieve the effects of overcoming low biomass, good effluent quality, and offsetting energy consumption for aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

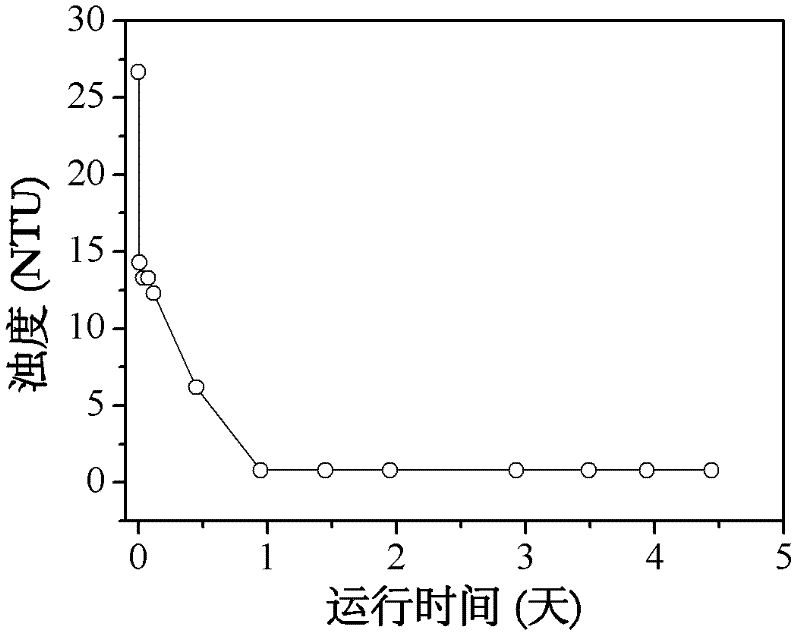

[0042] Embodiment 1: when influent COD (chemical oxygen demand, chemical oxygen demand), concentration is 12.6-439.1mg / L, this bioelectrochemical membrane reactor is to the removal rate of COD 82.5-93.9%; When the ammonia nitrogen concentration is 13.6-41.7mg / L, the removal rate of ammonia nitrogen by the bioelectrochemical membrane reactor is 92.7-99.6%, and the removal rate of TN is 27.6-60.7%.

Embodiment 2

[0043] Embodiment 2: When the hydraulic retention time of the anode chamber is 0.25-5h, the coulombic efficiency of the anode chamber of the bioelectrochemical membrane reactor is 0.51-12.4%, the removal rate of COD is 5.5-79.1%, and the removal rate of ammonia nitrogen 5.3-24.5%.

Embodiment 3

[0044] Embodiment 3: the volume load in the anode chamber is 0.5-22.6kg COD / (m3d), and the maximum power density produced by this bioelectrochemical membrane reactor is 4.35W / m 3 , the maximum current density is 18.32A / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com