Draught fan for truck bed of off-gas heating dumper

A technology for exhaust heating and dump trucks, which is applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc., and can solve problems such as shifting of the center of gravity of the car, overturning, and inability to completely unload materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

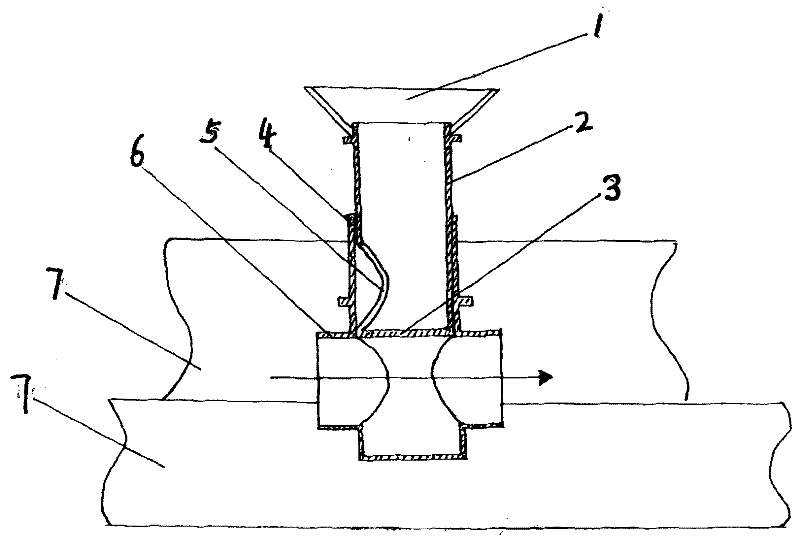

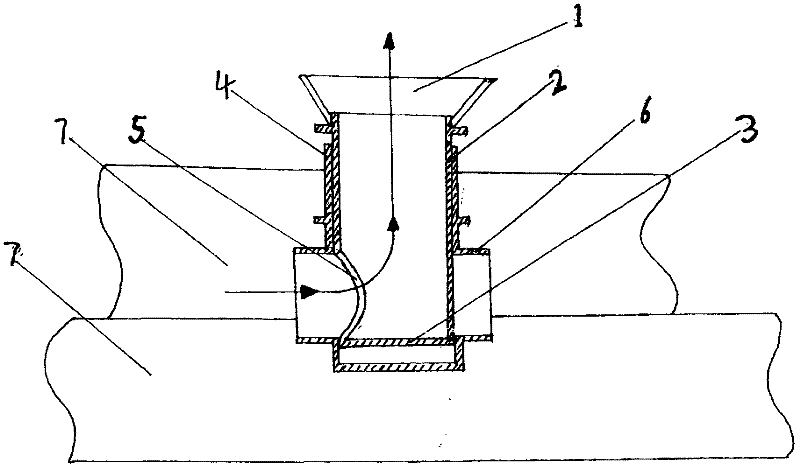

[0011] Such as figure 1 , figure 2 As shown, the air intake device is composed of a lower tapered guide cover 1, an inner casing 2, a lower sealing plate 3, an outer casing 4, an air inlet 5, an exhaust pipe 6, and a chassis frame 7. The outer sleeve 4 is a pipe body with openings at both ends, fixed on the vehicle chassis frame 7, the outer sleeve 4 is vertically connected with the exhaust pipe 6 of the dump truck in the middle, and the inner sleeve 2 is installed in the outer sleeve 4. The outer sleeve can move up and down freely, and the lower sealing plate 3 is fixed at the bottom of the inner sleeve, so the lower end of the inner sleeve 2 closes the upper opening, and the lower part of the inner sleeve 2 is provided with an air inlet 5 at the position aligned with the exhaust pipe . When the carriage was lifted, the inner casing 2 moved upwards, the lower sealing plate 3 stopped the air-flow from entering the inner casing 2, and the exhaust pipe 6 was unimpeded before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com