Double-stator single-rotor rare earth permanent magnet motor

A rare earth permanent magnet, single rotor technology, applied in synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc. It can solve the problems of large and difficult to realize the motor, and achieve the effect of solving the design problems of low-voltage and high-power motors, improving the output power and efficiency, and controlling the temperature rise of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

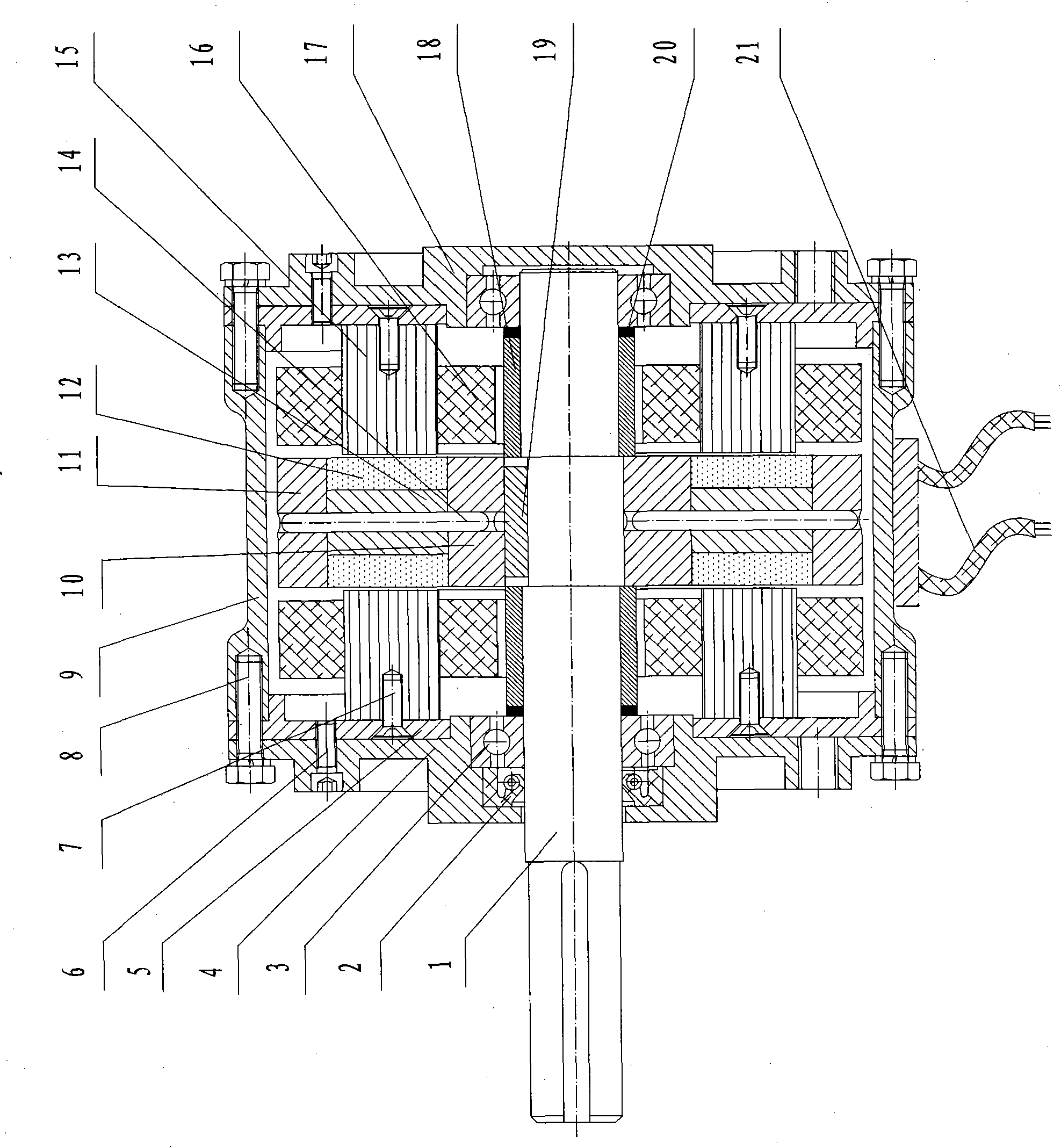

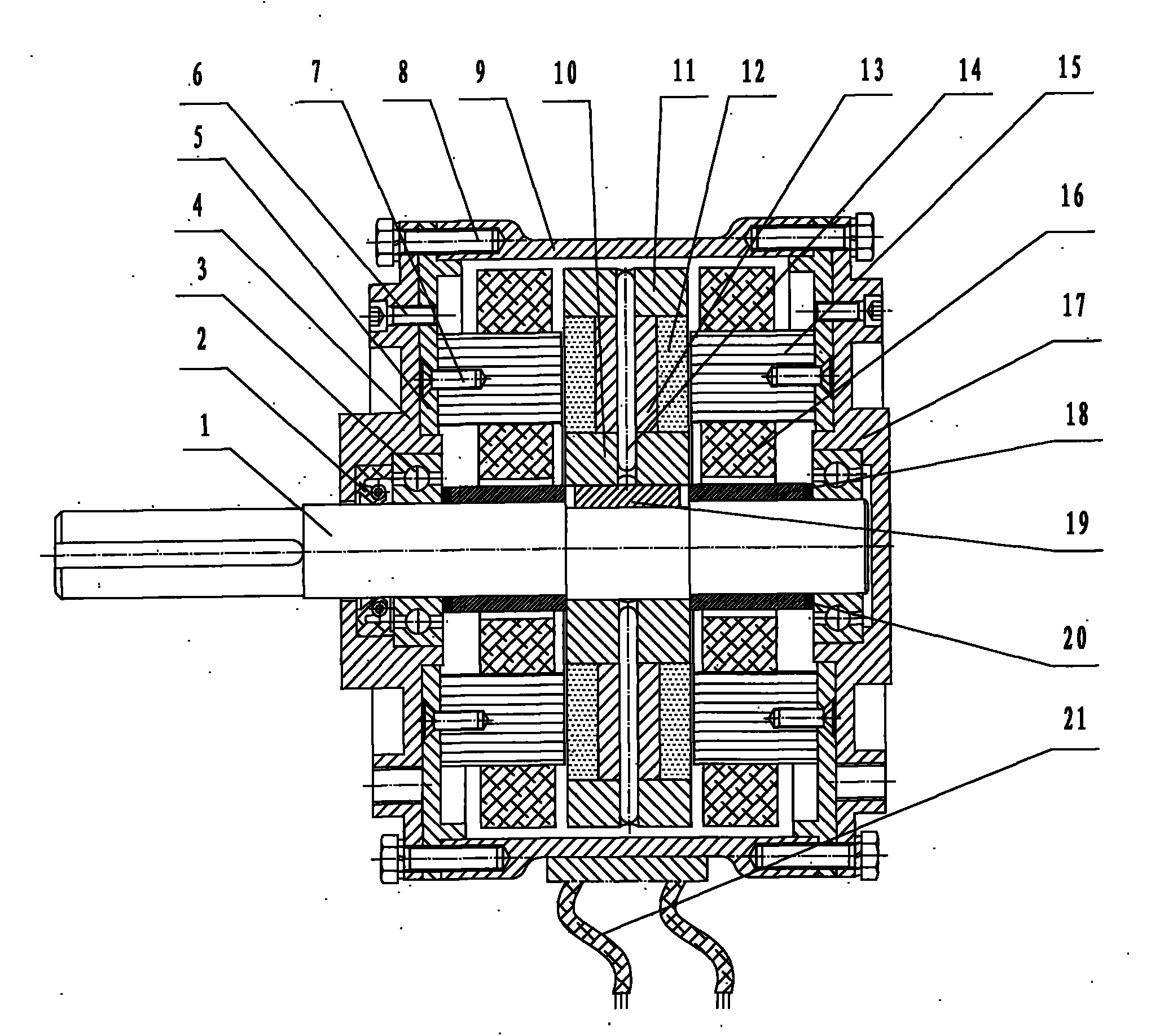

[0023] Such as figure 1 Shown:

[0024] The embedding slots of the stator core (15) are designed on the end face, distributed uniformly and radially along the circumference, the height and slot depth are in the axial direction, and the stacking thickness is in the radial direction; the slot type, number of slots, height, thickness, and motor operating voltage, The output power and working speed match;

[0025] Riveting the magnetic conduction ring (13), the inner magnetic isolation ring (10) and the outer magnetic isolation ring (11) with a naked copper rod (14) into a rigid body;

[0026] Several pieces of rare earth magnets (12) are pasted or embedded in the magnetic ring (13) according to a certain polarity to form a rotor (make one);

[0027] Fix the stator core (15) to the inner end cover (5) with hexagon socket head cap screws (6); embed the stator winding (16) into the stator core (15); align the winding head and end, weld, shape and bind the winding The lead wire (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com