Lithium ion battery, cathode slurry and preparation method thereof

A lithium-ion battery and negative electrode slurry technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable active substances mixed with glue, normal production impact, equipment alarms, etc., to shorten the preparation time and shorten the Wetting time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

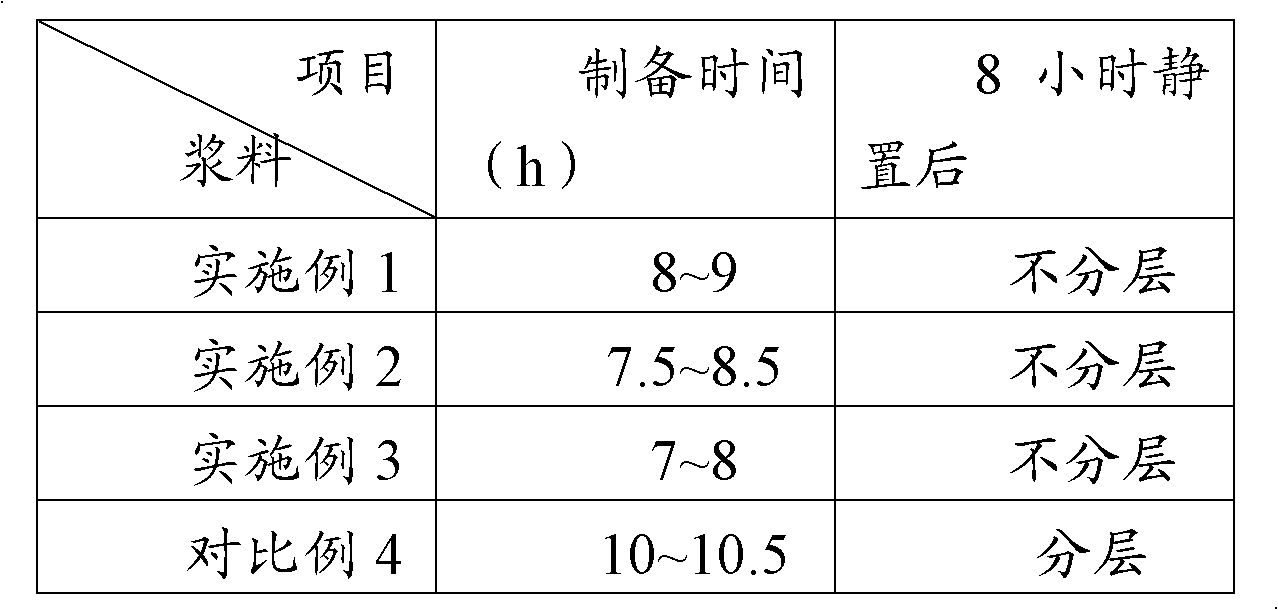

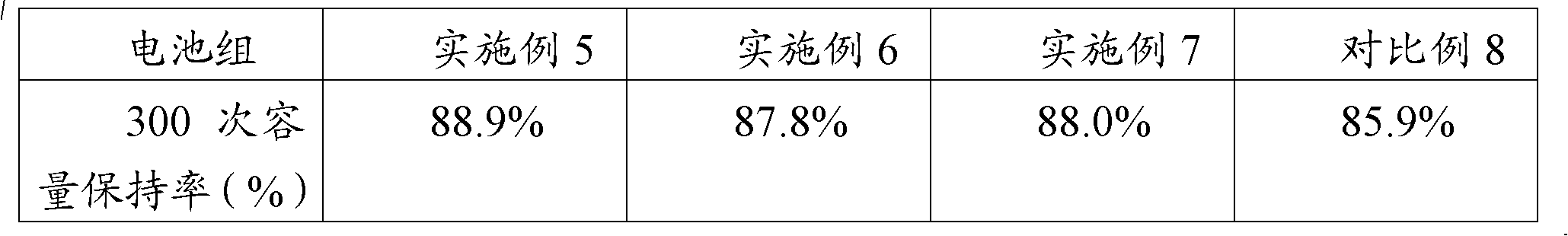

[0022] A negative electrode slurry for a lithium ion battery is prepared, and the process includes the following steps.

[0023] (101) Mix 2000 g of negative active material natural graphite and 50 g of negative conductive agent carbon black in a stirred tank, add lubricant methanol 15 g, and stir for 5 to 40 minutes until uniformly mixed;

[0024] (102) The additive sodium carboxymethylcellulose CMC30g is added in the stirrer and stirred;

[0025] (103) Mix 2000 g of negative electrode solvent deionized water and 60 g of negative electrode binder SBR to make a rubber compound, add the material in the above-mentioned agitator to the rubber compound, and mix and stir for 8 hours to make a negative electrode slurry.

Embodiment 2

[0027] A negative electrode slurry for a lithium ion battery is prepared, and the process includes the following steps.

[0028] (201) 2000 g of natural graphite, a negative electrode active material, and 50 g of negative electrode conductive agent carbon black are mixed in a stirred tank, and a total of 200 g of lubricant nitrogen methyl pyrrolidone NMP and acetone are added, and stirred for 5 to 40 minutes until uniformly mixed;

[0029] (202) The additive sodium carboxymethylcellulose CMC30g is added in the stirrer and stirred;

[0030] (203) Mix 2000 g of negative electrode solvent deionized water and 60 g of negative electrode binder SBR to make a rubber compound, add the material in the above-mentioned agitator to the rubber compound, and mix and stir for 7.5 hours to make a negative electrode slurry.

Embodiment 3

[0032] A negative electrode slurry for a lithium ion battery is prepared, and the process includes the following steps.

[0033] (301) 2000g of natural graphite, the negative electrode active material, and 50g of the negative electrode conductive agent, carbon black, are mixed in a stirred tank, and a total of 600g of lubricant methanol and ethanol are added, stirred for 5 to 40 minutes until uniformly mixed;

[0034] (302) The additive sodium carboxymethyl cellulose CMC30g is added in the stirrer and stirred;

[0035] (303) Mix 2000 g of negative electrode solvent distilled water and 60 g of negative electrode binder SBR to make a rubber compound, add the material in the above-mentioned agitator to the rubber compound, and mix and stir for 7 hours to make a negative electrode slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com