Component System Set For Manufacturing Motor Vehicles Of Different Motorization Variants

A technology for motor vehicles and solutions, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve logistics costs and other problems, achieve the effects of reducing pipeline length, saving storage and development costs, and simplifying process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

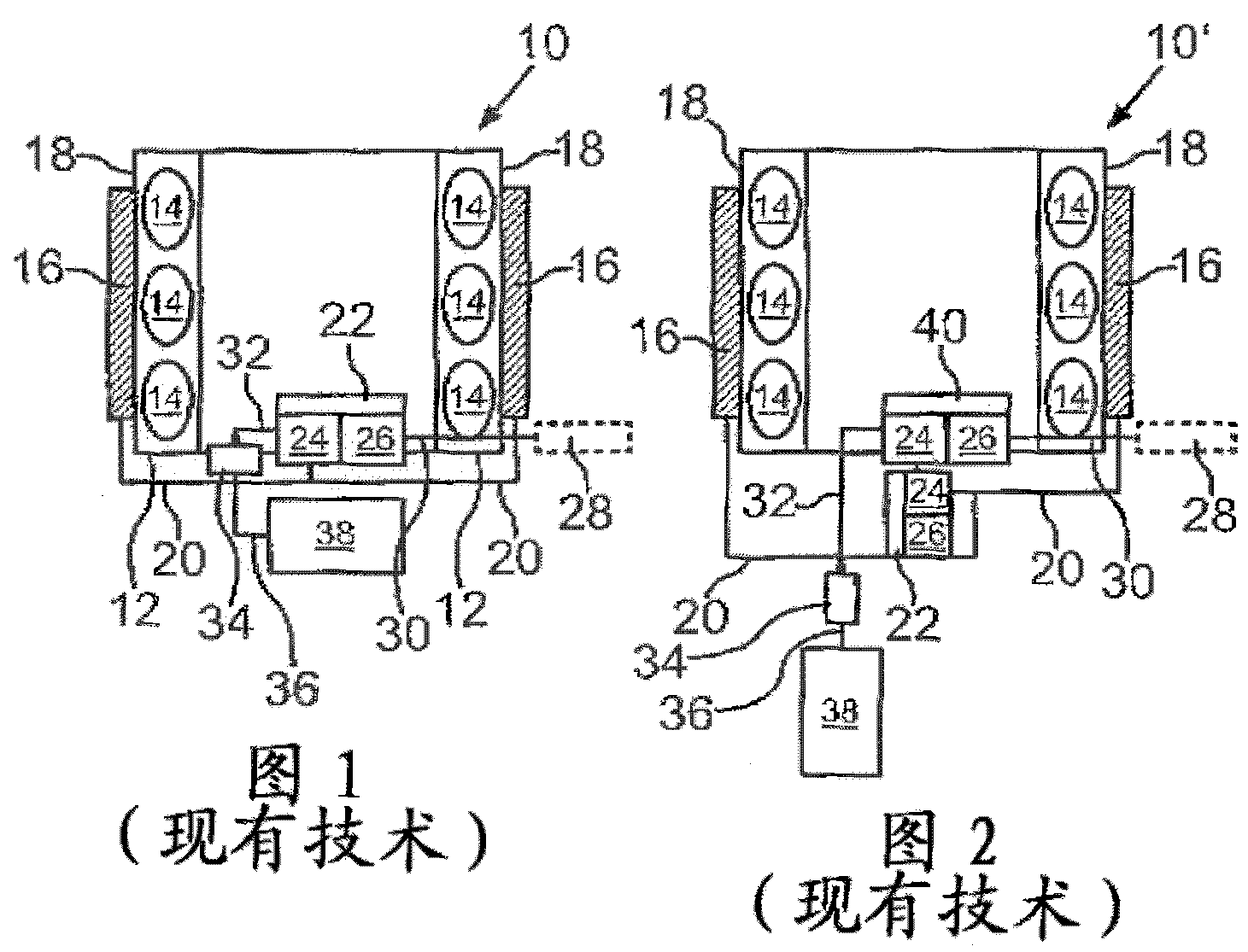

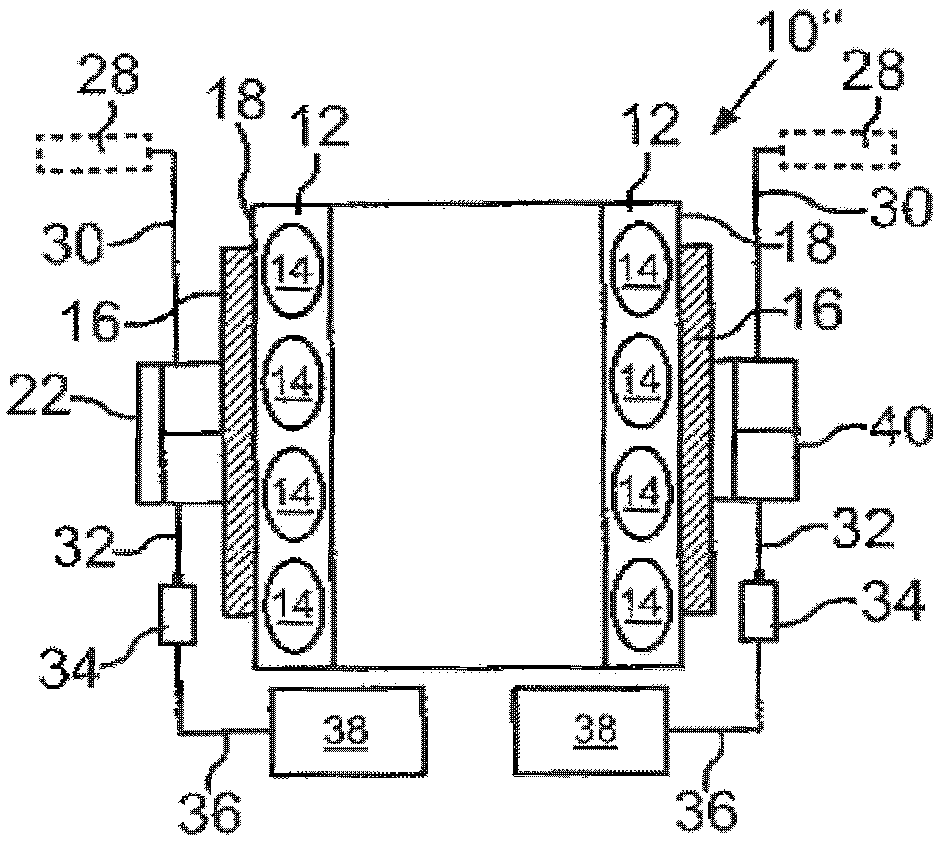

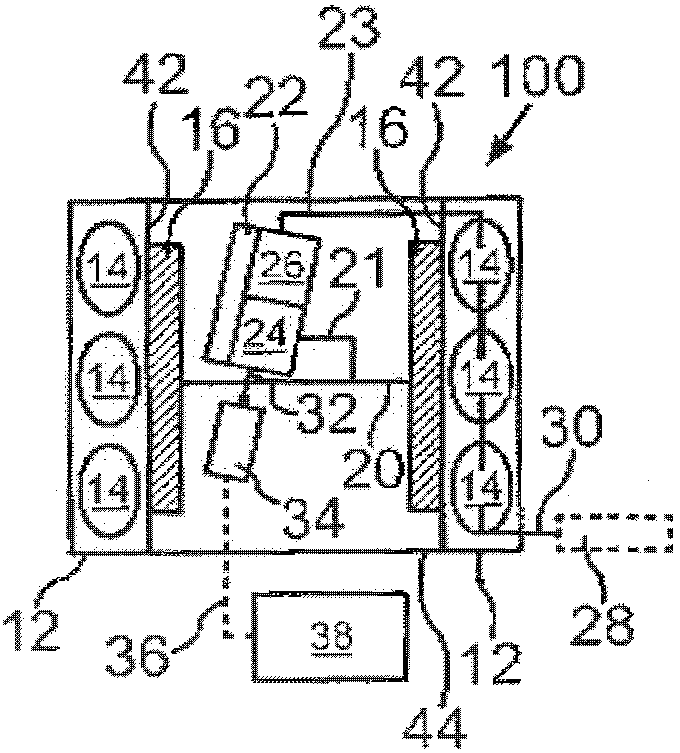

[0023] According to the state of the art, the engine indicated as a whole by 10 is a six-cylinder diesel engine of V-shape construction. The engine 10 thus has two cylinder banks 12 each comprising three cylinders 14 which are inclined relative to one another in a V-shape and which drive a common crankshaft. Exhaust manifolds 16 of the cylinders 14 are disposed on an outer side 18 of the cylinder bank 12 . Exhaust lines 20 lead from these exhaust manifolds 16 to an exhaust gas turbocharger 22 , where hot exhaust gas enters the turbocharger 22 on the turbine side 24 and drives a turbine of the turbocharger there. The turbine drives a compressor wheel arranged on the compressor side 26 of the turbocharger 22 , which sucks in ambient air through an air filter 28 via a line 30 and via other, not shown here The pipe feeds the cylinder 14. The exhaust gas flowing out again at the turbine side 24 of the turbocharger 22 is conducted via a line 32 into an oxidation catalyst 34 , wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com