Hinge

A hinge and joint technology, applied in the field of hinges, can solve the problems of improper distribution of spring return force, failure to consider, spring elastic fatigue, etc., to avoid elastic fatigue and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

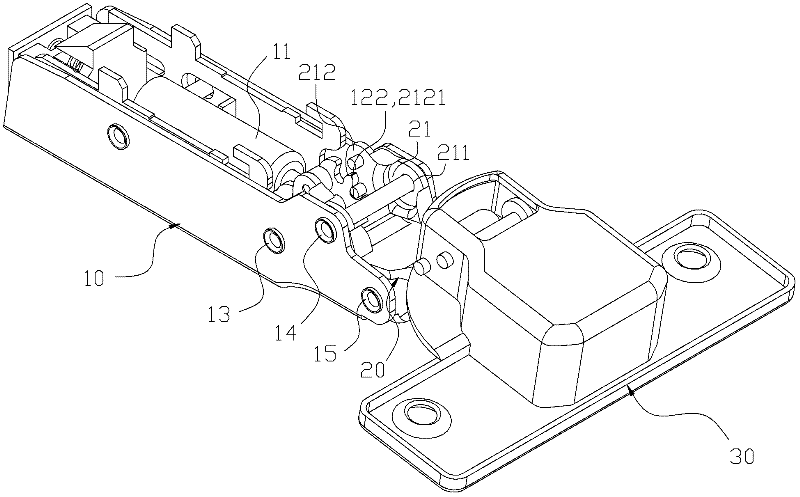

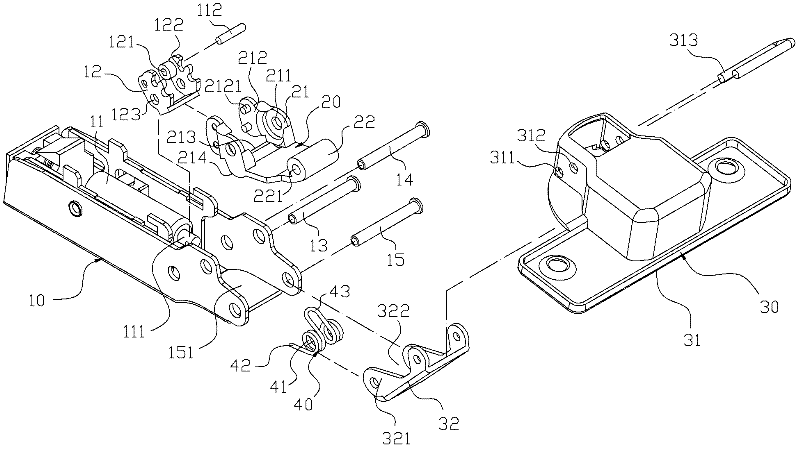

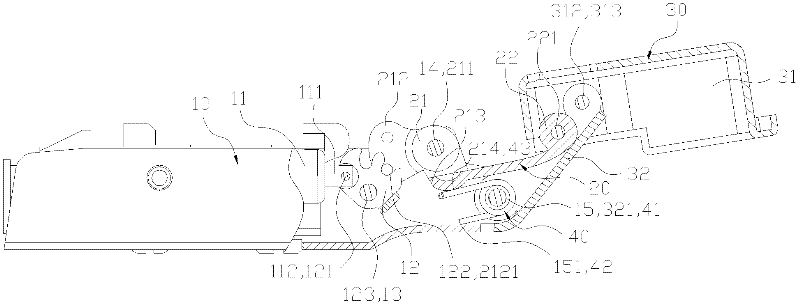

[0040] according to figure 1 with 2 As shown, the hinge of the present invention includes a hinge body 10, a linkage member 20, a movable seat 30, and an elastic member 40. The hinge body 10 is hinged with a buffer member 11, and the telescopic rod 111 of the buffer member 11 A shaft bolt 112 is penetrated at the front end, and the telescopic rod 111 is hinged with a swing block 12 through the shaft bolt 112; the swing block has two connecting pieces connected to each other, and the swing block 12 is provided with one end A first pivot hole 121 is provided through the two connecting pieces. The telescopic rod 111 is placed between the two connecting pieces, and is pivotally connected to the swing block 12 through the cooperation of the shaft bolt 112 and the first pivot hole 121. The block 12 is provided with two engaging concave arcs 122 on the upper edges of the two connecting pieces, and a second pivot hole 123 passing through the two connecting pieces is arranged at the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com