Preparation method of laser cladding coating of tridimensional space stacking net additive

A three-dimensional space, laser cladding technology, applied in laser welding equipment, metal processing equipment, heating inorganic powder coating, etc., can solve the problems of single material, cracks, pores, etc., achieve high energy density, simple preparation method, no Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

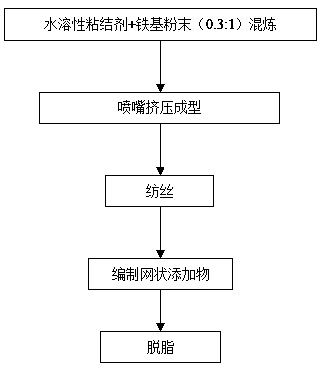

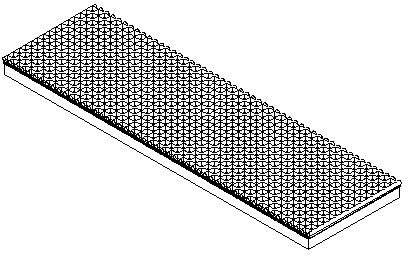

[0029] (1) Manufacture of three-dimensional space stacking net-like additives: iron-based powder is Fe55 powder bonded with water-soluble

[0030] agent (polyethylene glycol and polymethyl methacrylate prepared at a volume ratio of 4:1), the mixture is extruded through the nozzle for spinning, and the metal wire with a thickness of 0.25~1.0mm , Weaving into three kinds of nets with different pitches, the pitches are 0.25, 0.5, 1.0mm respectively. The water-soluble binder and Fe55 powder were mixed at a volume fraction ratio of 0.3:1. Fe55 powder: Hall flow rate is 0.50 s / g, bulk density is 3.8g / cm 3 , the hardness is 23-27HRC, the mass percentage of Cr is 18.00%, Ni is 3.00%, B is 2.60%, Si is 3.50%, C is 1.20%, and Fe is the balance.

[0031] (2) Pre-treatment of the surface of the austenitic stainless steel base material, the process is: the base material is 1Cr18Ni9Ti austenitic

[0032] The body stainless steel first uses 180# metallographic sandpaper to polish the surf...

Embodiment 2

[0043] (1) Manufacture of three-dimensional space stacking mesh additives: knead nickel powder and water-soluble binder to form a mixture, extrude the mixture into metal wires with a diameter of 0.25~1.0mm through spinning nozzles, and weave them into Three meshes with different spacing, the spacing is 0.25, 0.5, 1.0mm respectively.

[0044] (2) Pre-treatment of the surface of the austenitic stainless steel substrate: firstly polish the surface of the austenitic stainless steel substrate 1Cr18Ni9Ti to be clad, and then clean it with absolute ethanol;

[0045] (3) Laser cladding material preparation: put the metal powder in an oven and dry it at a temperature of 100-150°C for 1-2 hours. After natural cooling, add it to the powder feeder, and coat it on the preset surface by synchronous powder feeding. On the surface of the austenitic stainless steel substrate with three-dimensional space stacking mesh, the powder feeding rate is 0.2g / s, and the thickness of the coating reaches ...

Embodiment 3

[0050] (1) Manufacture of three-dimensional space stacking mesh additives: knead chromium powder and water-soluble binder to form a mixture, extrude the mixture into metal wires with a diameter of 0.25~1.0mm through spinning nozzles, and weave them into Three meshes with different spacing, the spacing is 0.25, 0.5, 1.0mm respectively.

[0051] (2) Pre-treatment of the surface of the austenitic stainless steel substrate: firstly polish the surface of the austenitic stainless steel substrate 1Cr18Ni9Ti to be clad, and then clean it with absolute ethanol;

[0052] (3) Laser cladding material preparation: Put the chrome powder in an oven and dry it at a temperature of 100-150°C for 1-2 hours. After natural cooling, add it to the powder feeder, and coat it on the preset surface by synchronous powder feeding. On the surface of the austenitic stainless steel substrate with three-dimensional space stacking mesh, the powder feeding rate is 0.2g / s, and the thickness of the coating reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com