High-cleanness blended gasoline and its preparation method

A blending and clean technology, applied in the field of blending gasoline, can solve the problems of unutilized, low yield, high cost, etc., and achieve the effects of good environmental protection, excellent flame resistance, and low emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The components are in the following percentages by weight: aromatics 45%, naphtha 25%, MTBE 8%, anti-knock additives 2%, heavy carbon five 9%, light carbon five 11%;

[0029] Described antiknock additive is by following weight percentage:

[0030] 1# Raw materials: 8% tert-butylbenzene, 42% methyl ether, 46% dimethyl phosphate, 4% methyl naphthalene;

[0031] 2# raw materials: tert-butylbenzene 16%, TAME 30%, dimethyl phosphate 50%, p-formic acid 4%;

[0032] 3# raw materials: TAME 40%, dimethyl phosphate 45%, p-formic acid 11%, methylnaphthalene 4%.

[0033] Under room temperature and normal pressure conditions, its preparation method adopts the following process steps:

[0034] Step 1: Put the raw materials that have not been used in the petrochemical plant as gasoline blending components into the raw material tank respectively, and use a sampler to take samples in the raw material tank for raw material analysis, mainly in accordance with the National III and Nation...

Embodiment 2

[0040] The components are in the following percentages by weight: aromatics 42%, naphtha 28%, MTBE 7%, additives 3%, heavy carbon five 10%, light carbon five 10%;

[0041] Described antiknock additive is by following weight percentage:

[0042] 1# raw materials: tert-butylbenzene 9%, methyl ether 45%, dimethyl phosphate 40%, methylnaphthalene 6%;

[0043] 2# raw materials: tert-butylbenzene 16%, TAME 38%, dimethyl phosphate 42%, p-formic acid 4%;

[0044] 3# raw materials: TAME 40%, dimethyl phosphate 45%, p-formic acid 9%, methylnaphthalene 6%.

[0045] Its preparation method is identical with embodiment 1.

Embodiment 3

[0047] Each component is in the following percentages by weight: aromatics 40%; naphtha 30%; MTBE 8%; antiknock additive 2%; heavy carbon five 8%; light carbon five 12%;

[0048] Described antiknock additive is by following weight percentage:

[0049] 1# raw materials: tert-butylbenzene 10%, methyl ether 40%, dimethyl phosphate 45%, methyl naphthalene 5%;

[0050] 2# Raw materials: 15% tert-butylbenzene, 35% TAME, 45% dimethyl phosphate, 5% p-formic acid;

[0051] 3# raw materials: TAME 45%, dimethyl phosphate 40%, p-formic acid 10%, methylnaphthalene 5%.

[0052] Its preparation method is identical with embodiment 1.

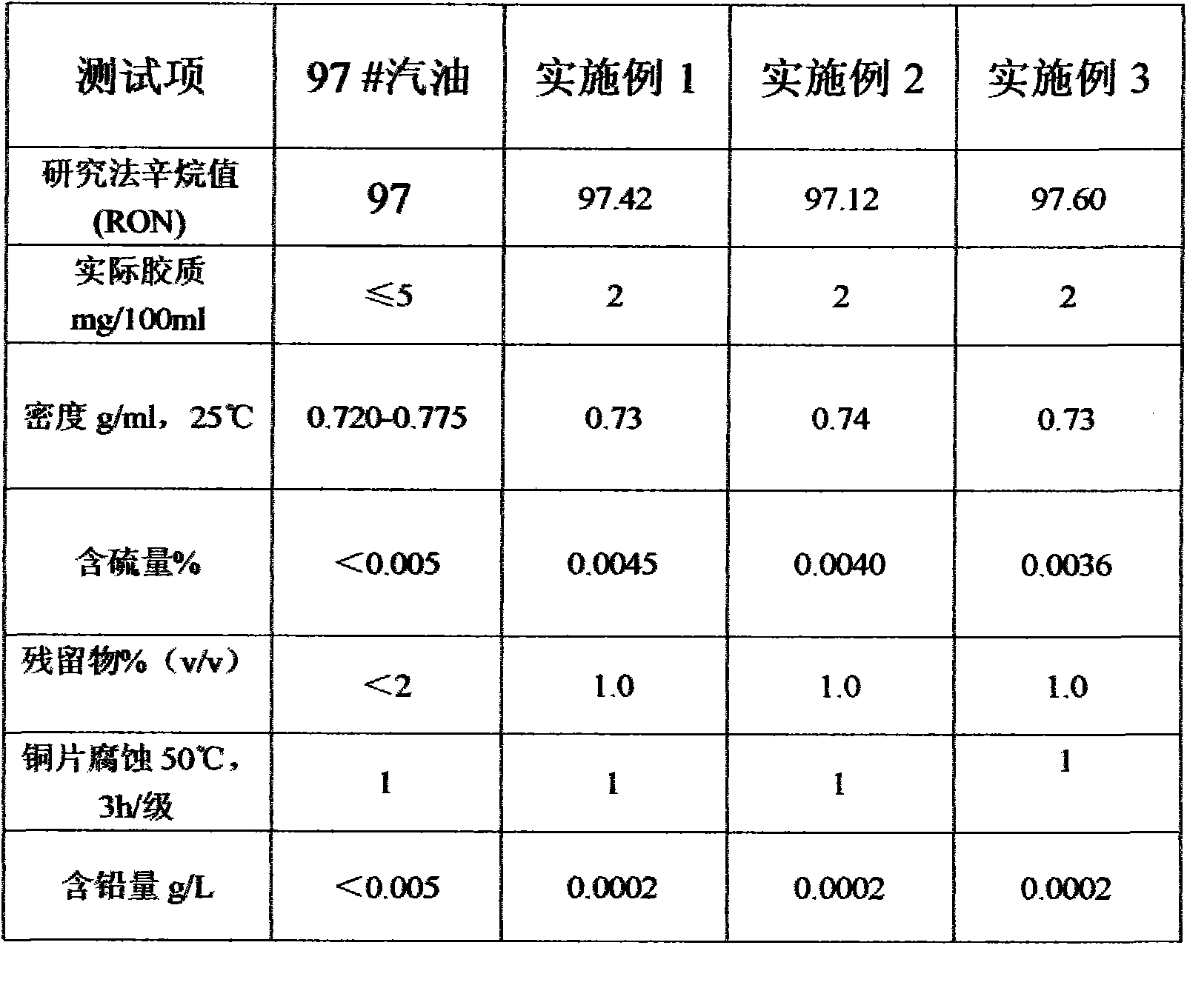

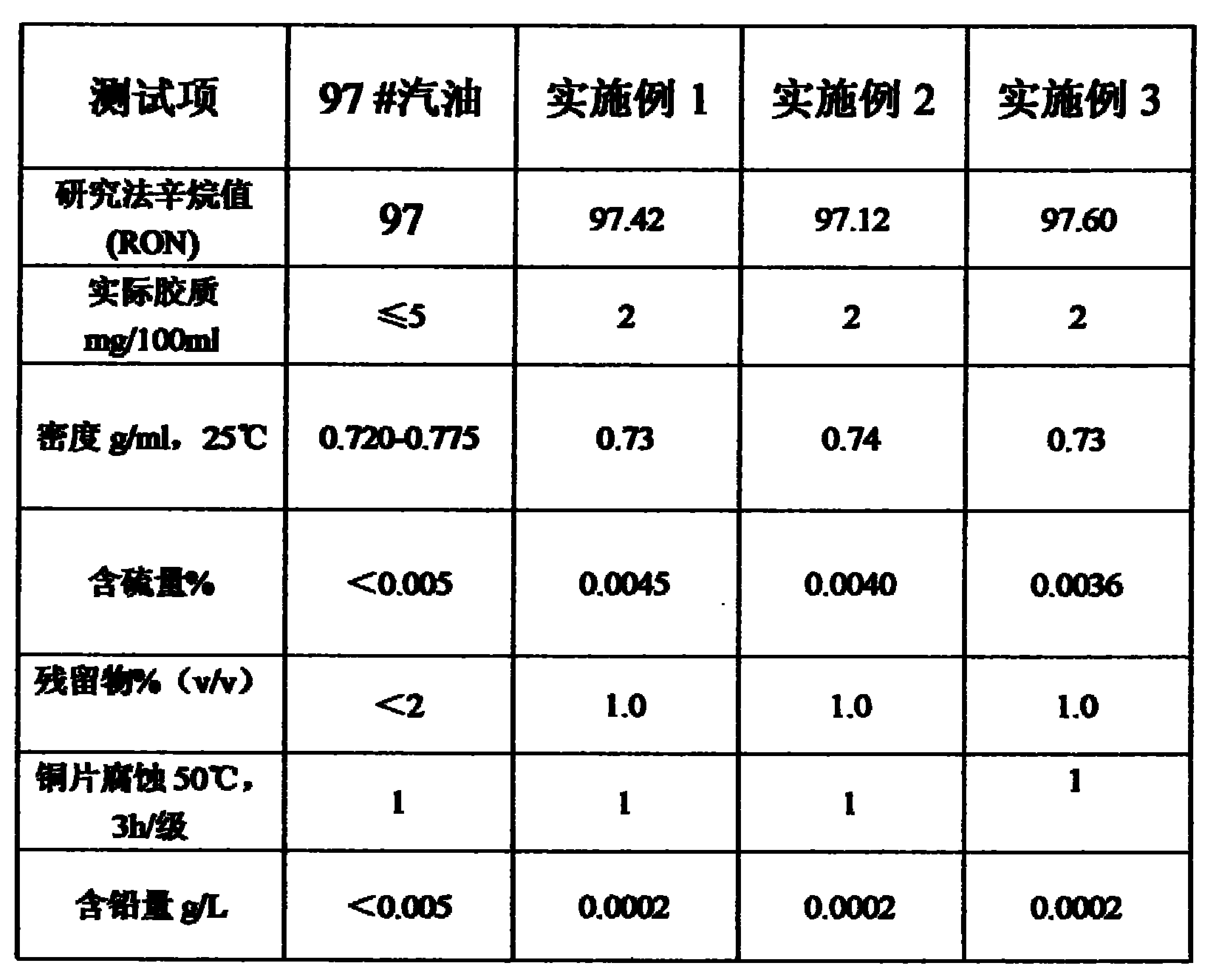

[0053] A kind of high-clean blend gasoline of the present invention and 97# gasoline quality index comparison example figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com